Lithium ion battery negative electrode piece packaged integrally by using diaphragm paper through coating and hot melting

A lithium-ion battery and negative electrode technology, which is applied in the field of lithium-ion batteries, can solve problems such as battery cell short-circuit hazards and affect battery safety, and achieve the effects of improving safety and reliability and eliminating short-circuit hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

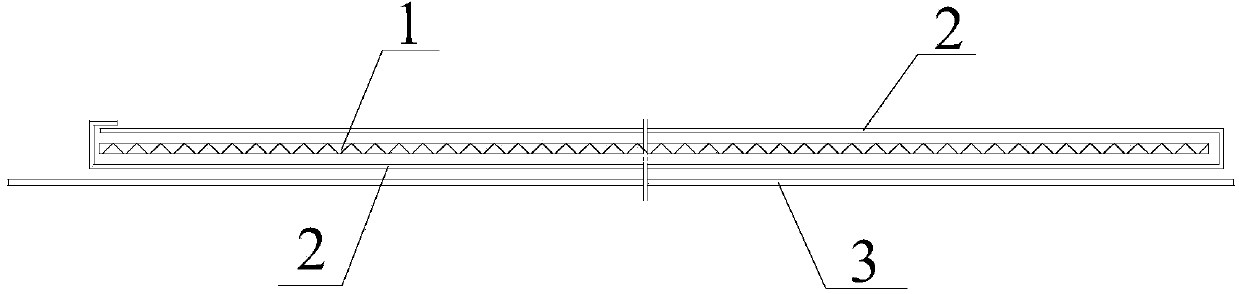

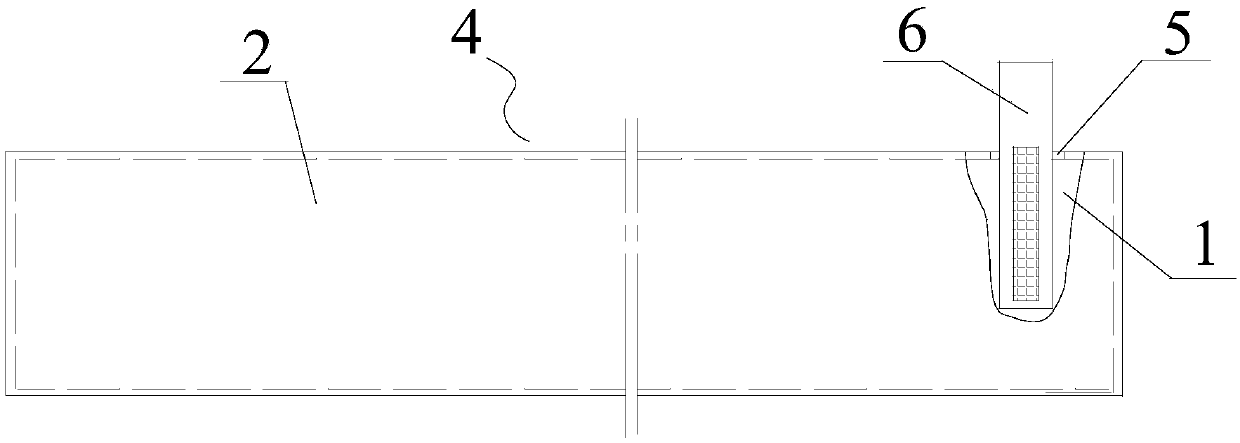

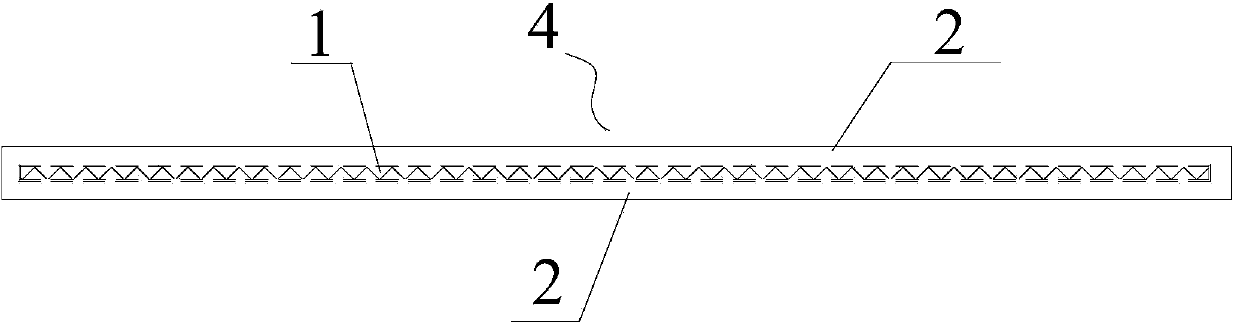

[0012] A negative electrode of a lithium-ion battery that is encapsulated by separator paper and encapsulated by hot-melt packaging, such as figure 2 and image 3 As shown, it includes a negative electrode sheet 1 of a lithium-ion battery, and the negative electrode sheet 1 is covered by two layers of separator paper 2 slightly larger than the negative electrode sheet 1, which is thermally fused around the separator paper 2 and packaged with the negative electrode sheet 1 as a whole. One end of the lithium ion battery negative electrode 4 packaged in one is provided with an opening 5 on one side of the separator paper 2 .

[0013] In the present invention, the negative electrode of the lithium-ion battery that is encapsulated with separator paper and hot-melt-packaged is integrated. When the battery core is wound, two layers of separator pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com