Recording disk drive device and resin component therefor

A technology for recording magnetic disks and drive devices, which is used in magnetic recording, data recording, recording information storage, etc. to achieve the effects of high cycle molding, improved reliability, and excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

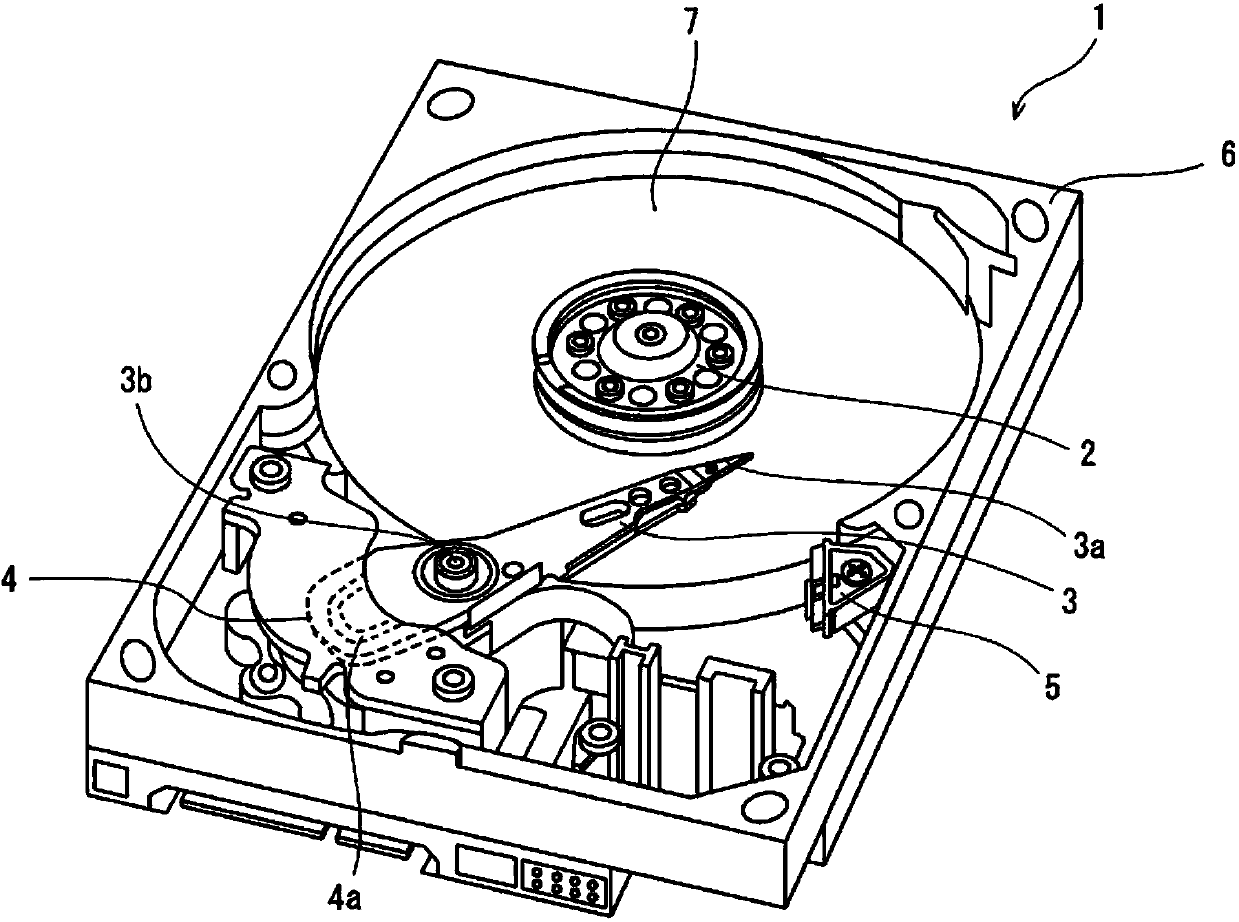

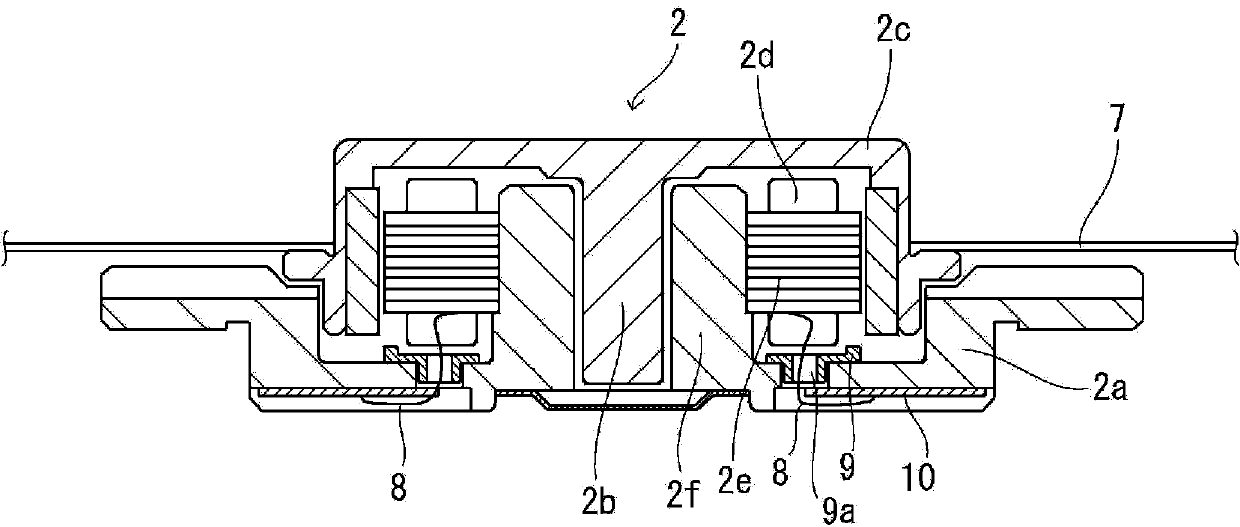

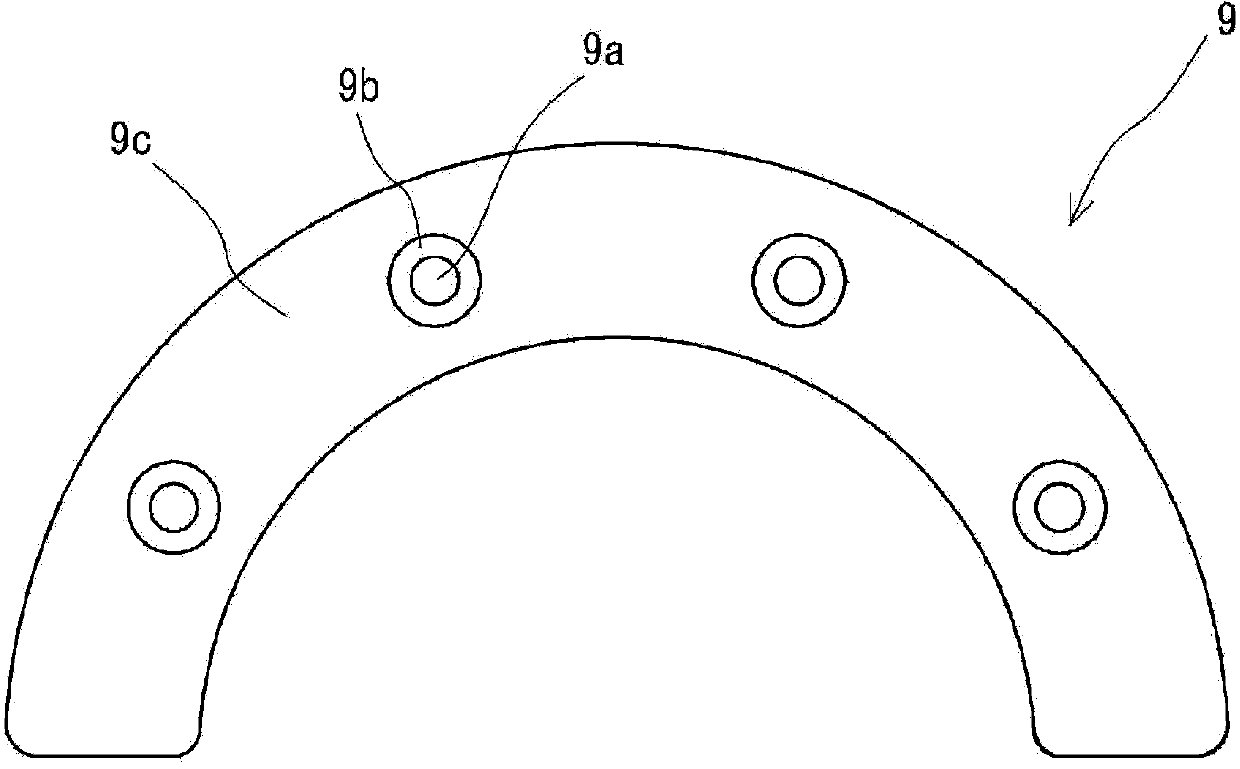

[0034] The resin part (resin molded body) of the present invention is (1) an insulating sleeve, (2) a carriage, or (3) a slideway used inside a recording disk drive device. The recording disk drive device using the resin part of the present invention has passed figure 1 Be explained. figure 1 It is a perspective view with the top cover of the recording disk drive unit removed. The recording magnetic disk drive device 1 rotates the magnetic disk 7 fixed to the motor 2 in the resin case 6, and at the same time reads information from the magnetic disk 7 and transfers information to the magnetic disk 7 by the reading head 3a provided at the front end of the swing arm 3. The disk device to write to. In addition, the carriage 4 integrally formed with the coil 4a for swinging the swing arm 3 around the shaft 3b is provided to maintain weight balance with the swing arm 3 . Furthermore, a slideway 5 for retracting the head 3 a when the magnetic disk 7 is stopped is provided in the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com