Stone mill and stone mill flour processing process

A stone grinding and flour technology, applied in grain milling, cocoa, grain processing, etc., can solve the problems of machine-made flour with many additives, low nutrient content, and rapid wear, and achieve fast wear, reduce the loss of nutrients, reduce The effect of the grinding wheel speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

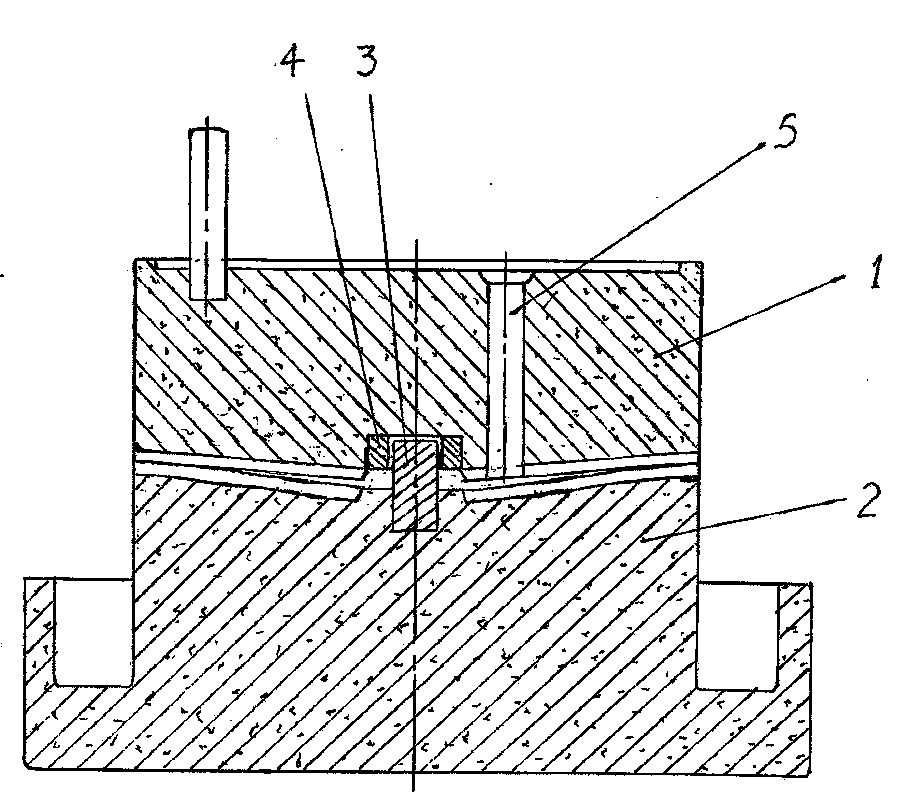

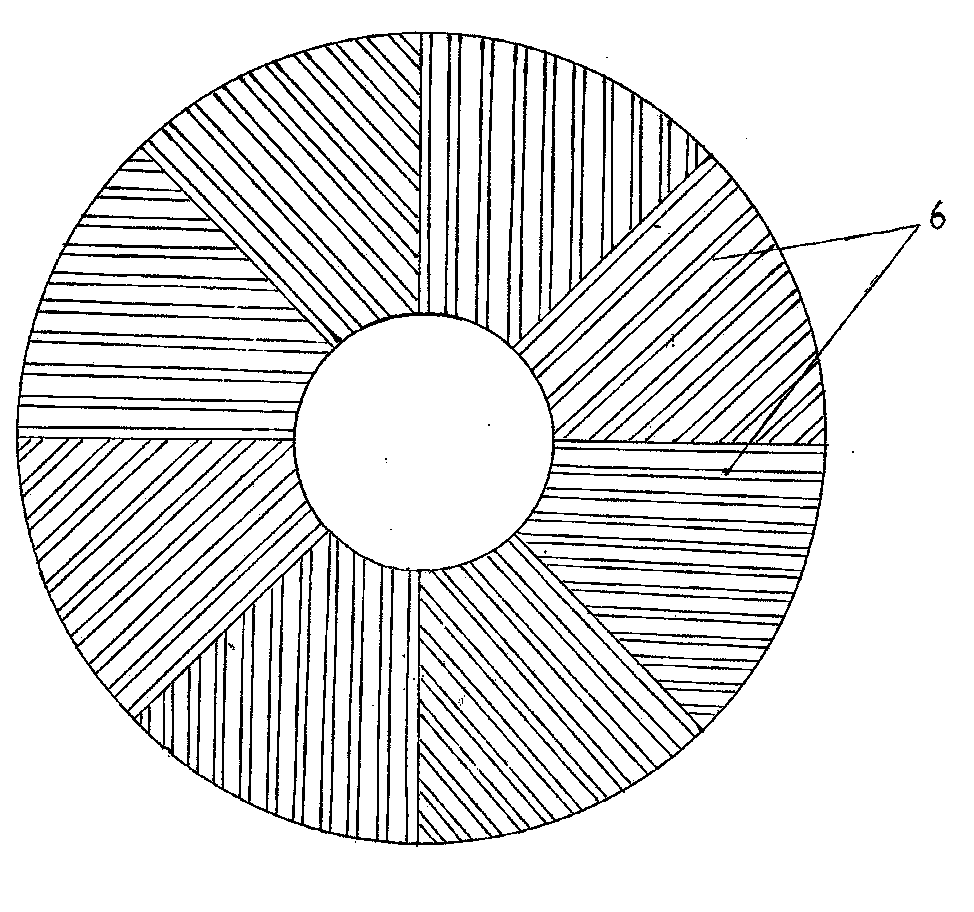

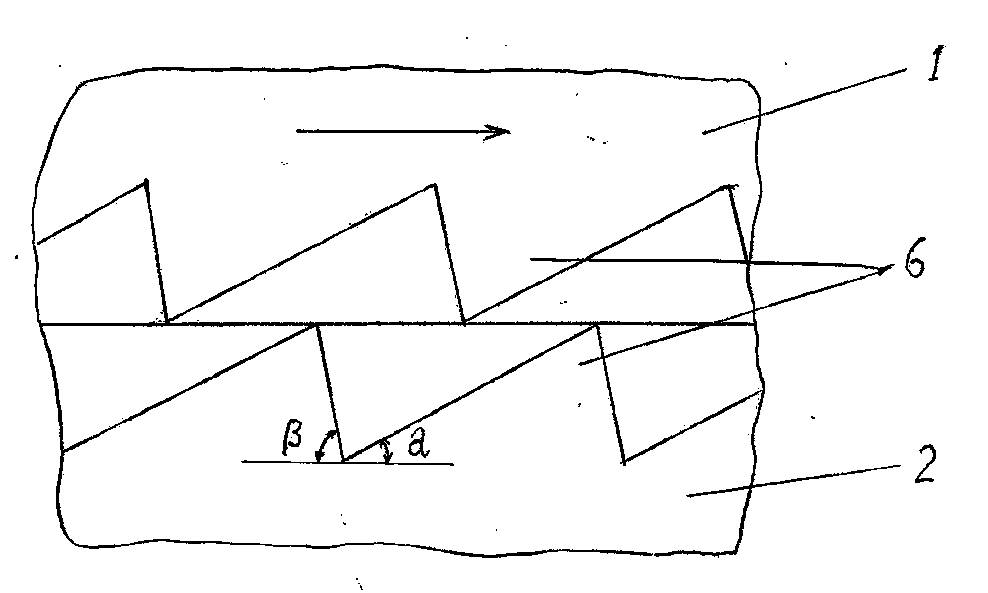

[0031] Such as figure 2As shown, the stone mill of the present invention comprises an upper millstone 1 and a lower millstone 2 carved with stones, a short vertical shaft 3 is fixed at the center of the lower millstone 2, a shaft sleeve 4 is arranged at the center of the upper millstone 1, and the shaft on the upper millstone 1 Cover 4 is socketed downwards on the short vertical shaft 3 on the lower millstone 2, so that the upper millstone 1 can rotate on the lower millstone 2, and can prevent the upper millstone 1 from slipping out of the lower millstone 2 during the rotation process. The top surface of the lower grinding disc 2 is a concave surface, and the bottom surface of the upper grinding disc 1 is a convex surface, and the gap space between the two is combined to form a grinding chamber. There is a blanking hole 5 on the upper grinding table 1, and the lower opening of the blanking hole 5 leads to the grinding chamber of the stone mill, and the wheat falling from the ...

Embodiment 2

[0035] A stone-milled flour processing technology is carried out in the following steps:

[0036] a. Cleaning and removing impurities: cleaning the raw grain to remove various impurities;

[0037] b. Moisturizing: According to the different types of raw grains, for hard wheat, the moisture content of the wheat is 13-20%, and the time of moisturizing is 17-25 hours; for soft wheat, the moisture content of the wheat is 13-16.5%, and the time of moisturizing is 13-17 hours Hour;

[0038] c. Grinding and milling: Utilize the stone mill of the present invention for grinding, the grinding speed is 15 rpm, the water content in the flour is controlled at 12.5-13.5, and the flour fineness is controlled at 70-160 orders. Grinding and milling to 6 times can meet the standard requirements of grade flour.

[0039] The present invention uses a special stone mill to process flour, low-speed grinding, and low-temperature processing, which avoids the damage of starch chains and the destructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com