General clamp for machining blade molded line

A blade profile and fixture technology, used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of affecting work efficiency, long debugging time, unstable blade profile processing dimensions, etc., to achieve strong versatility, The effect of improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

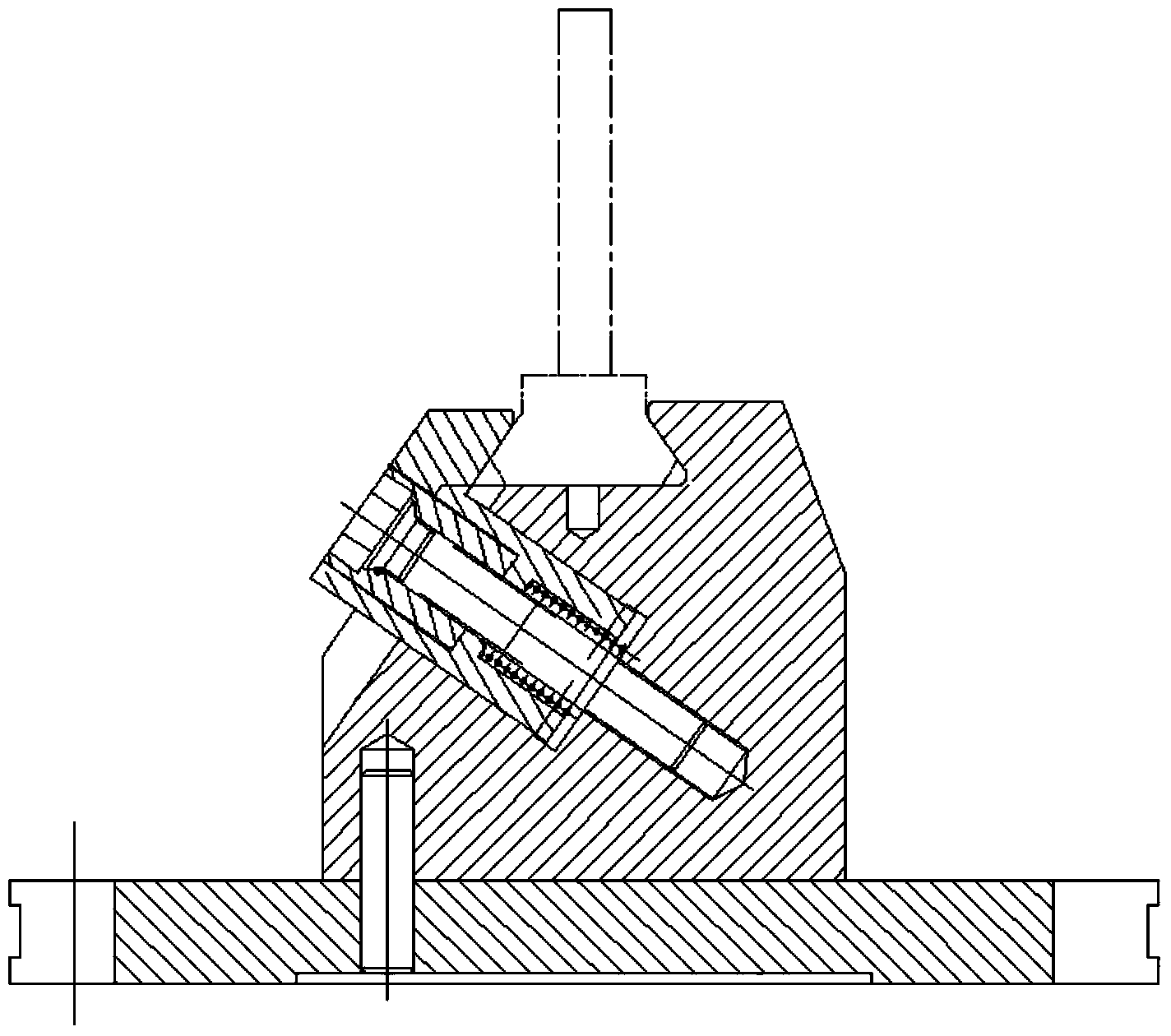

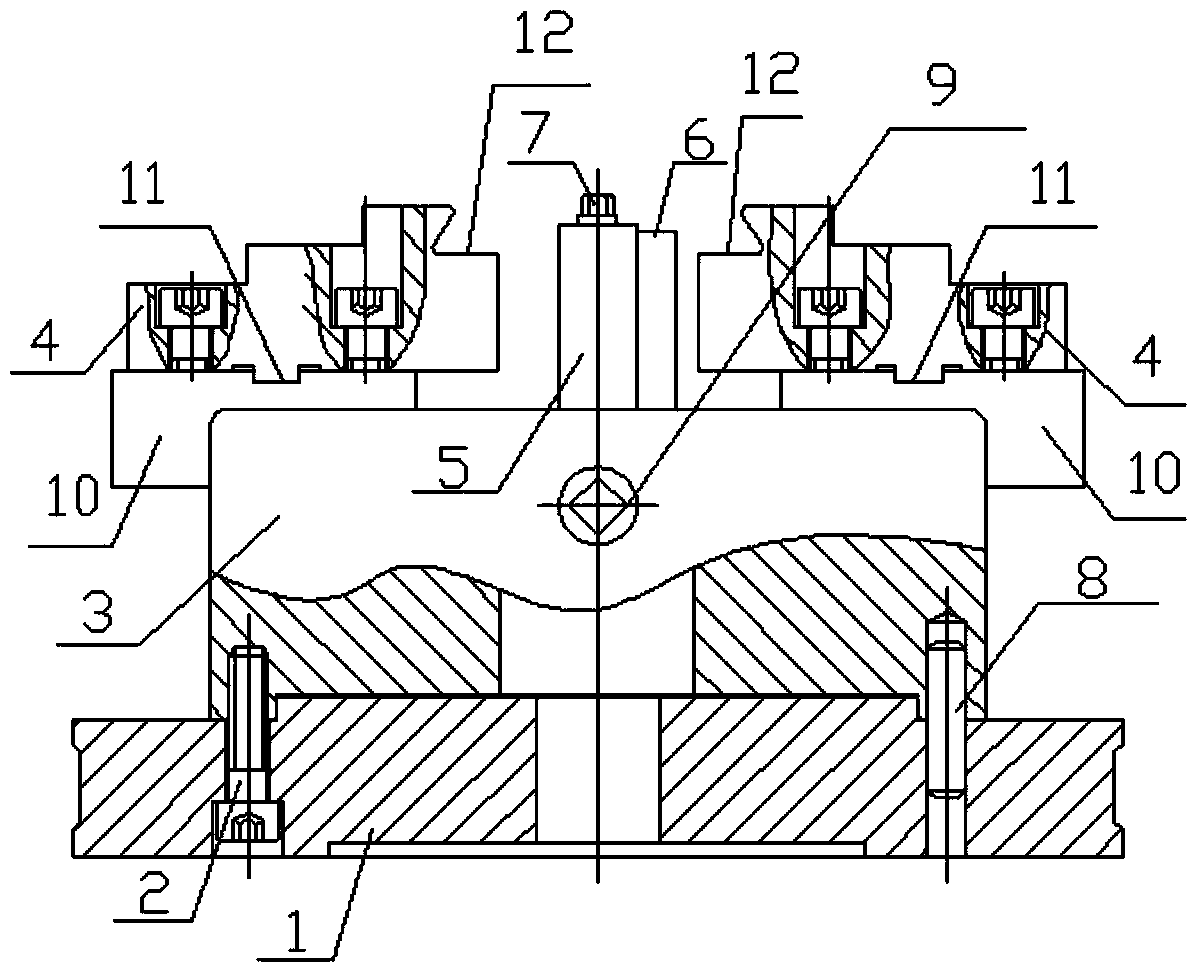

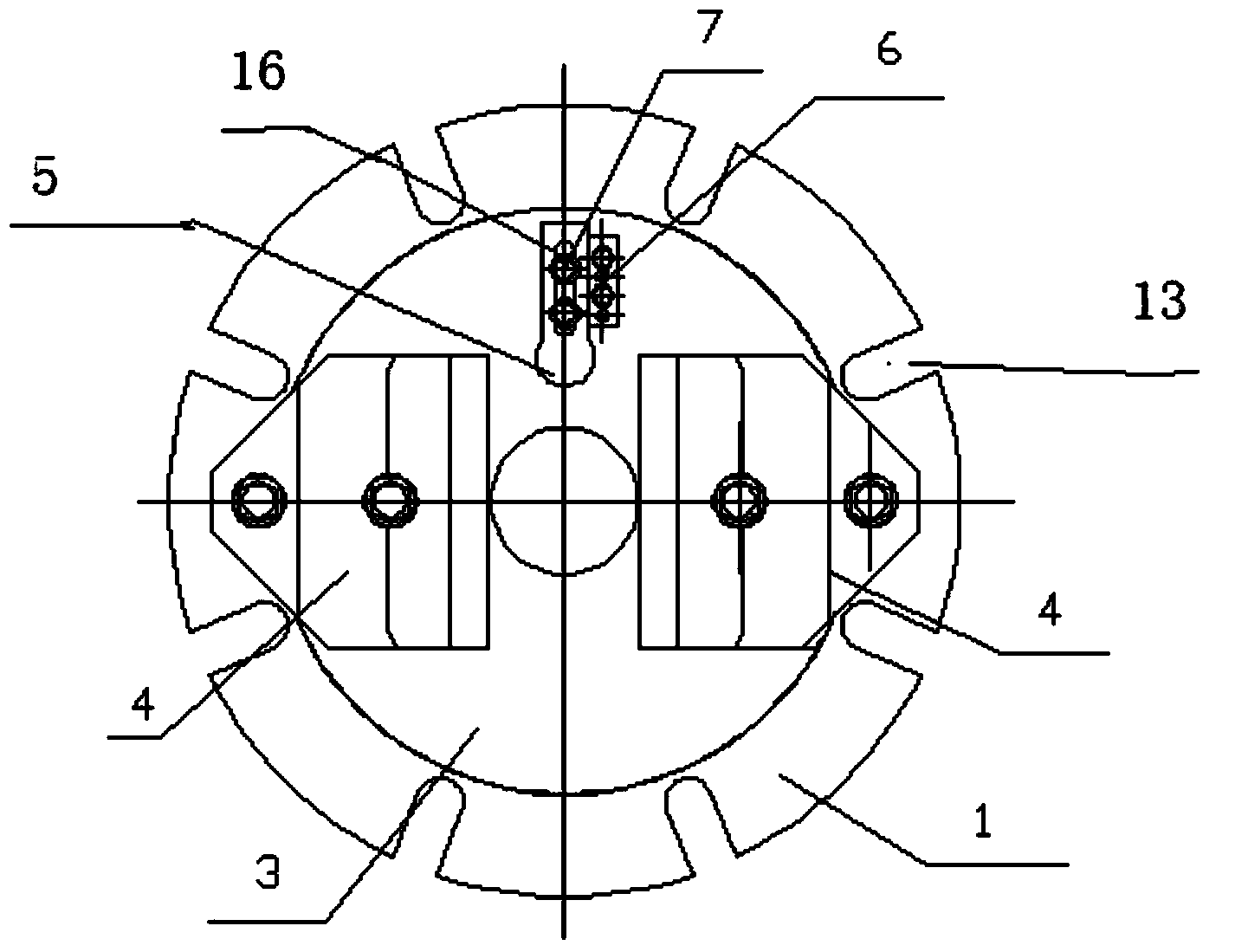

[0039] In this embodiment, the structure of the universal fixture for processing the profile of the blade is as follows: figure 2 , image 3 As shown, it includes a base 1, a self-centering two-jaw chuck, a blade tenon fixing seat 4, an adjustable positioning block 5 and a guide block 6. The structure of base 1 is as follows Figure 4 , Figure 5 As shown, it is a circular seat body, the seat body is provided with a central hole, and its periphery is provided with eight U-shaped grooves 13 equiangularly distributed, and its top surface is provided with a positioning protrusion for installing a self-centering two-jaw chuck. Table 14, the bottom surface of which is provided with grooves to reduce the contact surface with the blade profile processing equipment; the structure of the blade tenon fixing seat 4 is as follows Figure 6 , Figure 7 , Figure 8 As shown, the bottom surface is provided with a positioning structure for installation, and one side is provided with a j...

Embodiment 2

[0044] In this embodiment, the structure of the universal fixture for processing the profile of the blade is as follows: Figure 14 As shown, it includes a base 1 , a self-centering two-jaw chuck, a blade tenon fixing seat 4 , a block 18 , an adjustable positioning block 5 and a guide block 6 . The difference from Embodiment 1 is that two blocks 18 are added, and the two blocks are respectively installed on the sides of the two blade tenon fixing seats 4 facing the center of the self-centering two-jaw chuck body 3, and the two blocks are The provided jaws 12 are directed toward the center of the body 3 of the self-centering two-jaw chuck.

[0045] The universal jig for processing blade profiles described in this embodiment only needs to replace two blocks 18 instead of two blade tenon fixing seats 4 when the tenon root shape of the blade to be processed is changed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com