Foaming easily-degradable green packaging bottle

An easy-degradable, packaging bottle technology, applied in packaging, wrapping paper, packaging recycling, etc., can solve the problems of unfavorable environmental protection, liquid leakage, high production cost, etc., and achieve the effect of material saving, simple structure of the bottle body, and easy degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

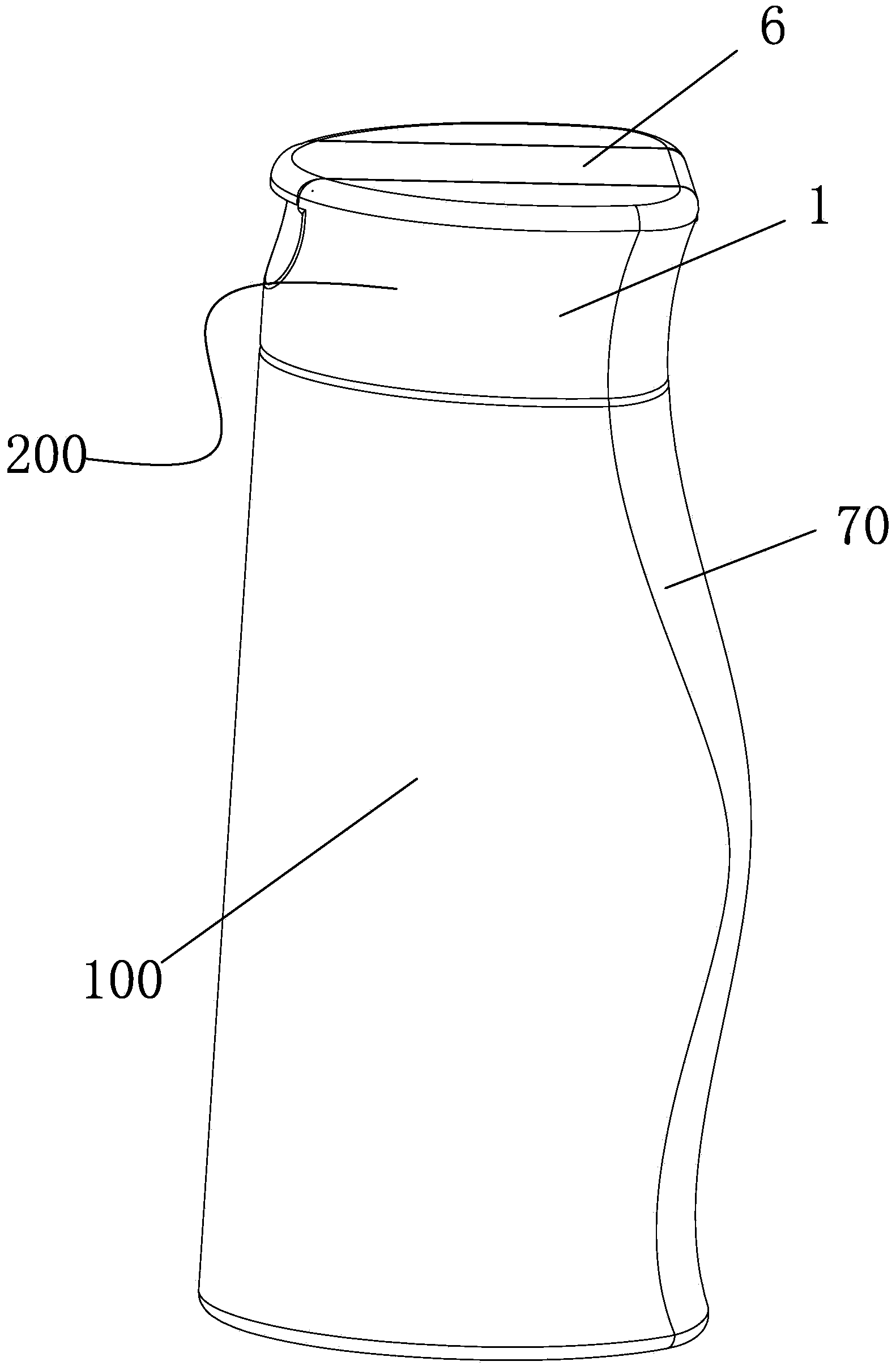

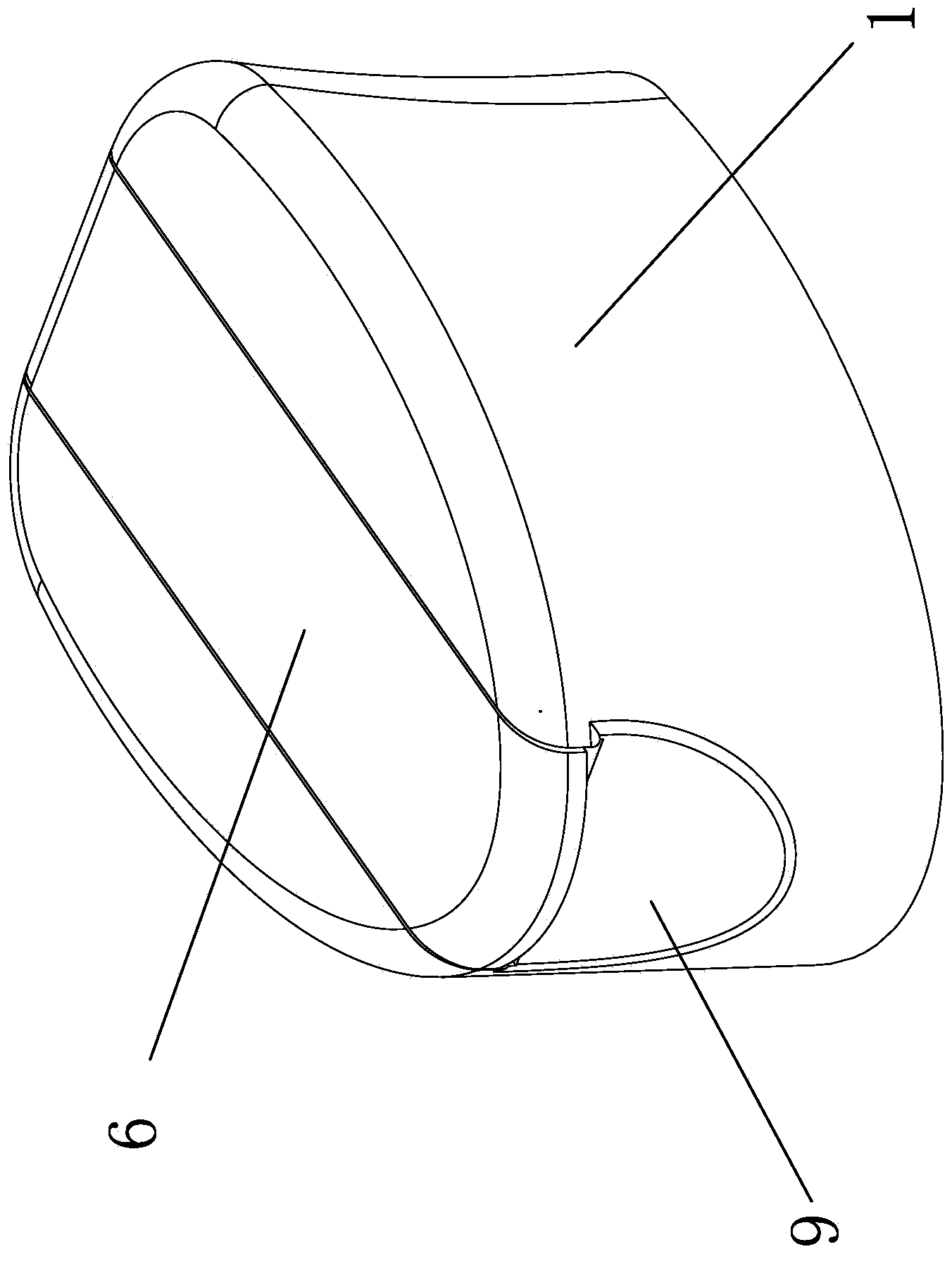

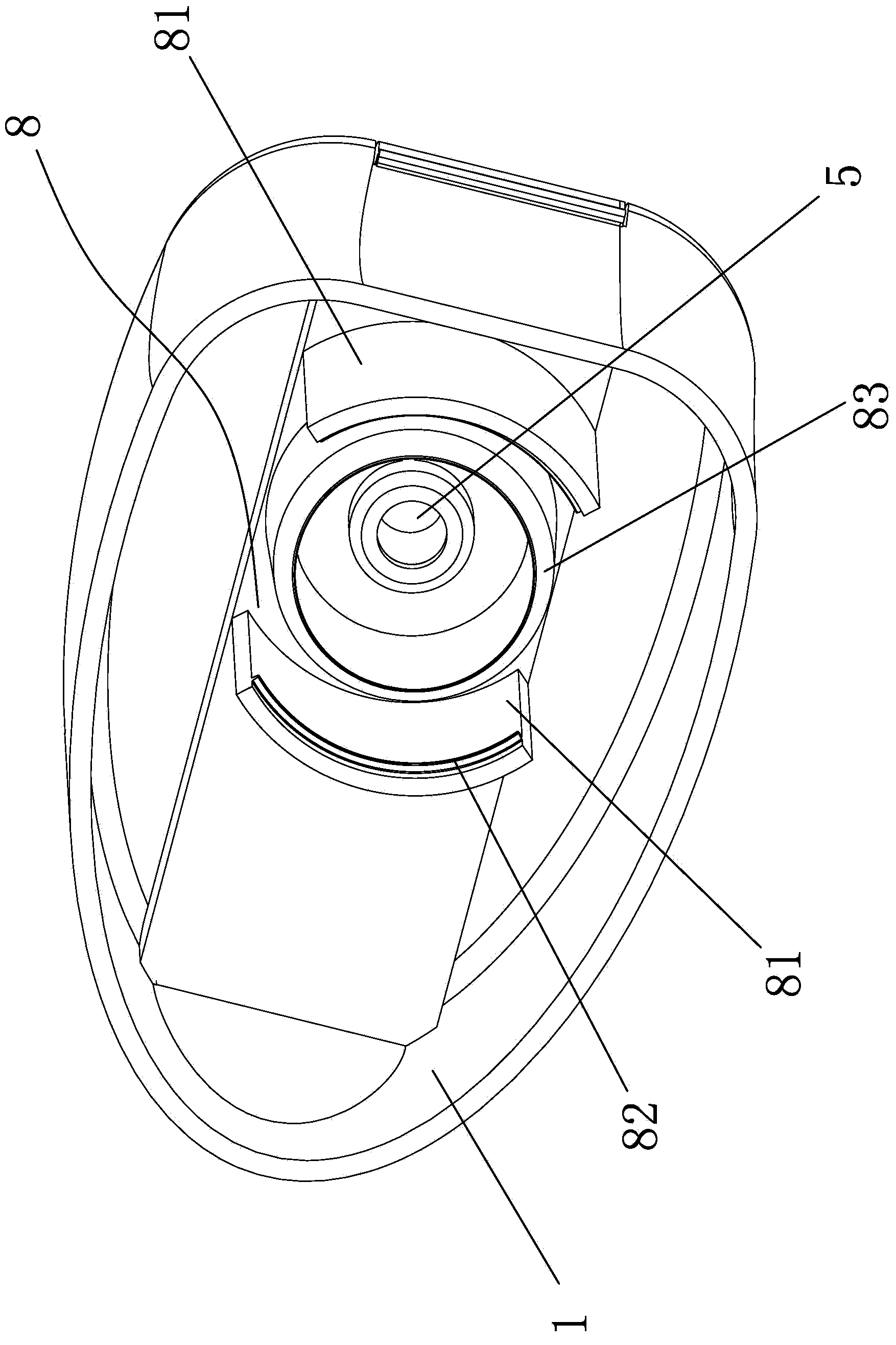

[0027] like Figures 1 to 6 A foaming easily degradable green packaging bottle shown includes a bottle body 100 and a bottle cap 200. The bottle cap 200 includes a foamed cap body 1, and a groove 4 is arranged on the top of the cap body 1 along the length direction. , an opening 5 is provided on the groove 4, a cover 6 that can be arranged in the groove 4 is hinged on the rear end of the groove 4, and a cover 6 is provided at the corresponding position of the cover 6 and the opening 5. There is a sealing column 7 capable of closing the opening 5, and a connection positioning mechanism 8 for connecting with the bottle body is provided in the foam cover body 1. The bottle body 100 includes a bottle body 10 made of recycled materials, The bottle mouth 20 connected with the inner cavity of the bottle body 10 is provided on the upper end surf...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap