Drilling and tapping combined clamp for inner gantry steel channel and outer gantry steel channel of forklift and machining method thereof

A combination fixture and channel steel technology, applied in metal processing equipment, metal processing machinery parts, clamping, etc., can solve the problems of reducing the accuracy of forklift parts, reducing the clamping accuracy, and affecting the efficiency of forklifts, so as to improve the clamping accuracy , Improving the processing accuracy and improving the efficiency of production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

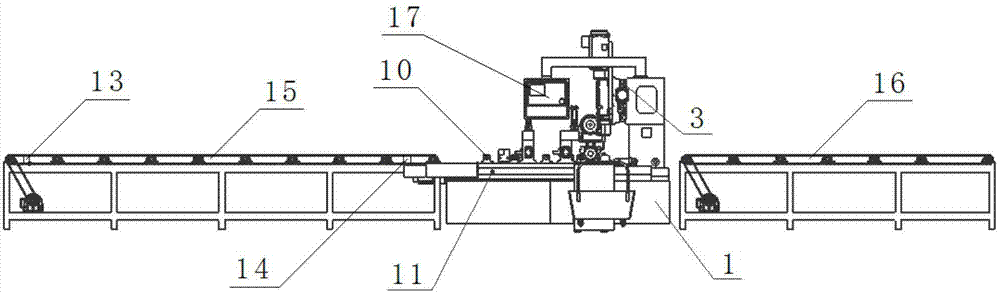

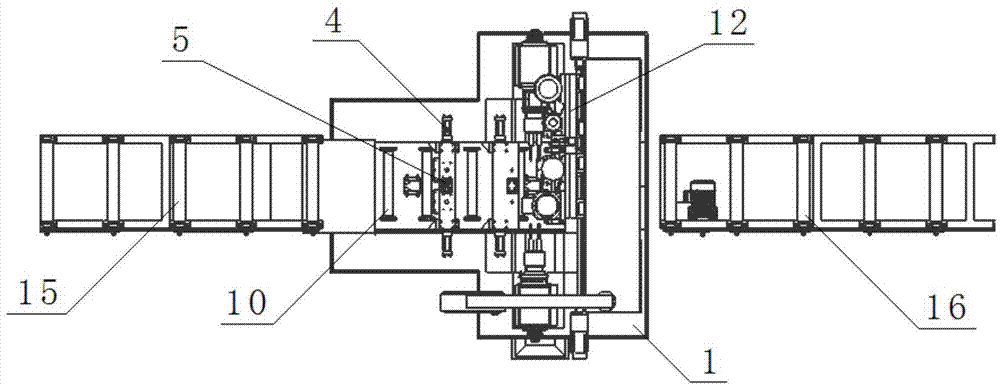

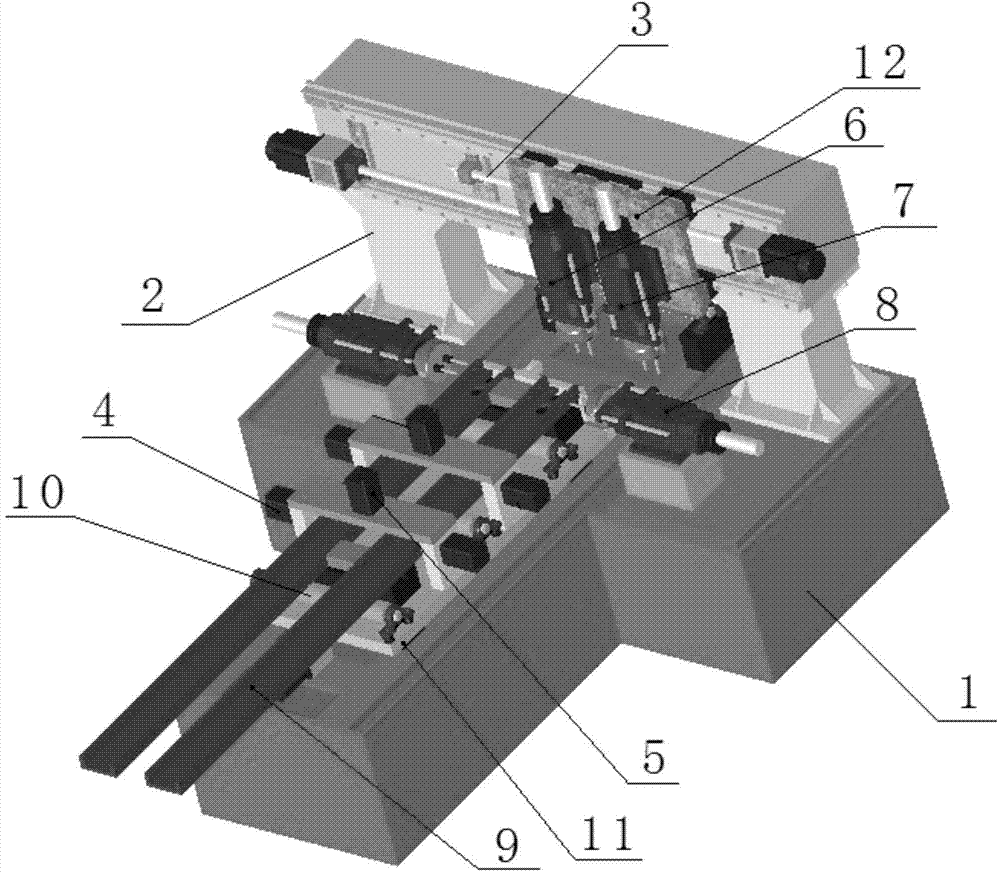

[0025] figure 1 It is a structural schematic diagram of the drilling and tapping combined fixture used for the channel steel of the inner and outer masts of the forklift according to the present invention, figure 2 for figure 1 A top view of the structure shown, image 3 It is a structural schematic diagram of the drill-tapping combination fixture part in the present invention. Depend on Figure 1-3 From the combination of the shown structures, it can be known that the drilling and tapping combined fixture for the channel steel of the inner and outer masts of the forklift includes a T-shaped base 1, and an inlet conveying roller table 15 and an outlet conveying roller table 16 located at both ends of the T-shaped base 1; the T-shaped base 1 is equipped with an X-direction CNC slide table 11, and the X-direction CNC slide table 11 is equipped with a conveying raceway 10 for automatically sending the workpiece 9 to be processed to the area to be processed; A pressing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com