Mesoporous titania material with highly crystalline framework, preparation method and application thereof

A mesoporous titanium dioxide, highly crystalline technology, applied in the field of physical chemistry, can solve the problems of pore wall collapse, affecting material structure and catalytic performance, specific surface area and pore volume decline, etc. The effect of sintering properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

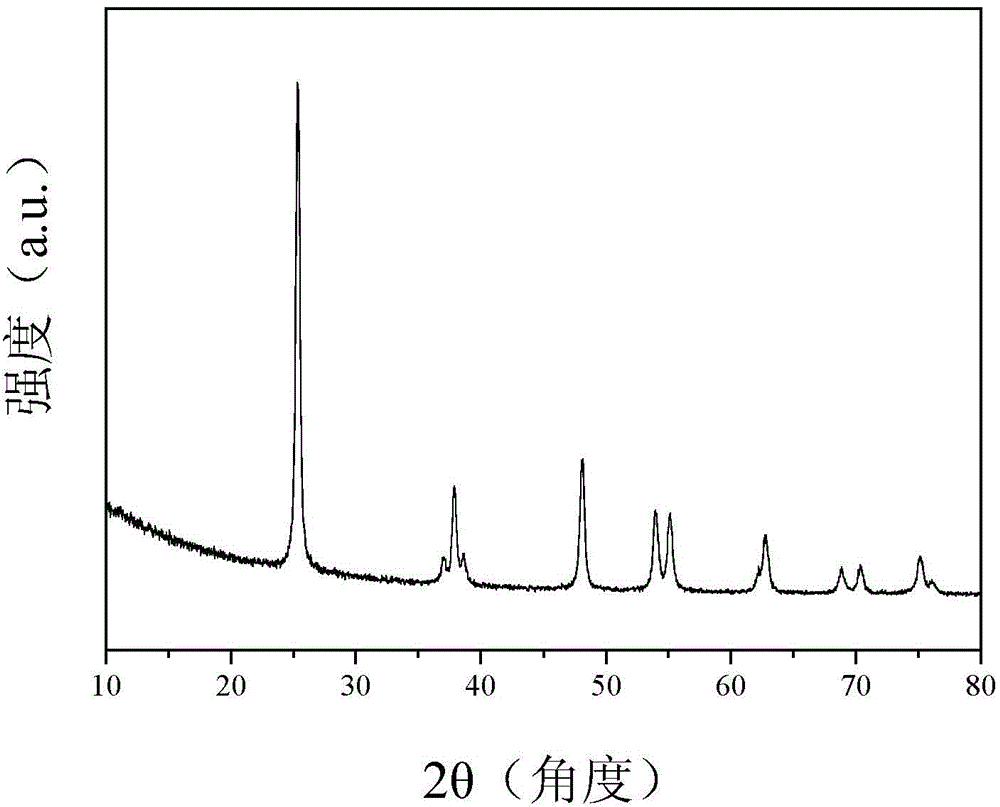

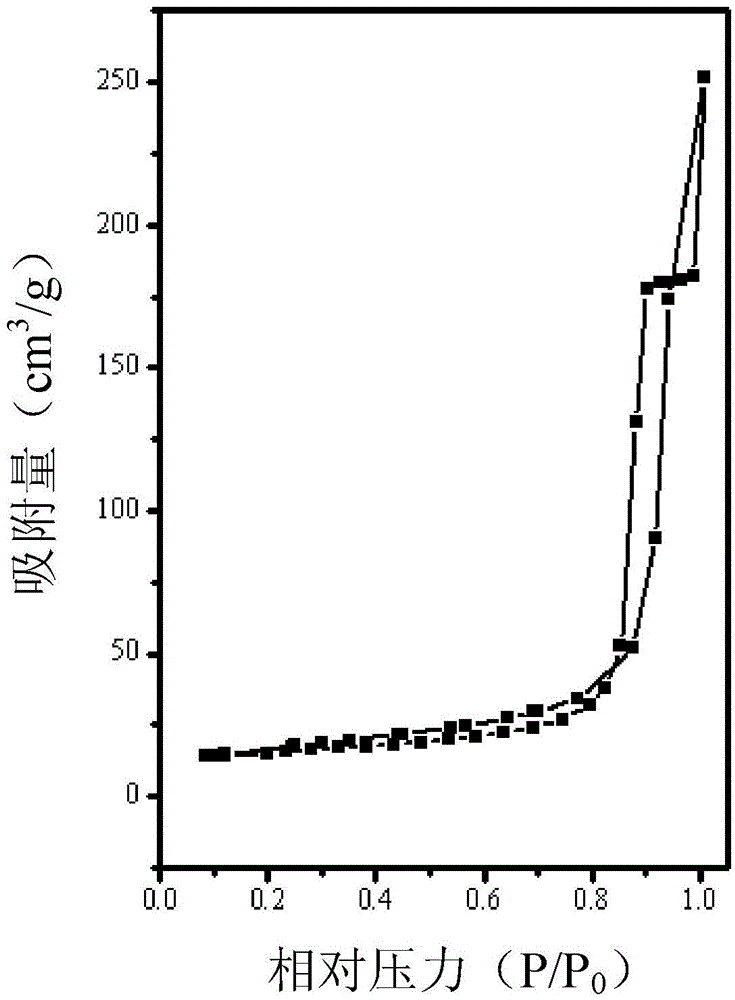

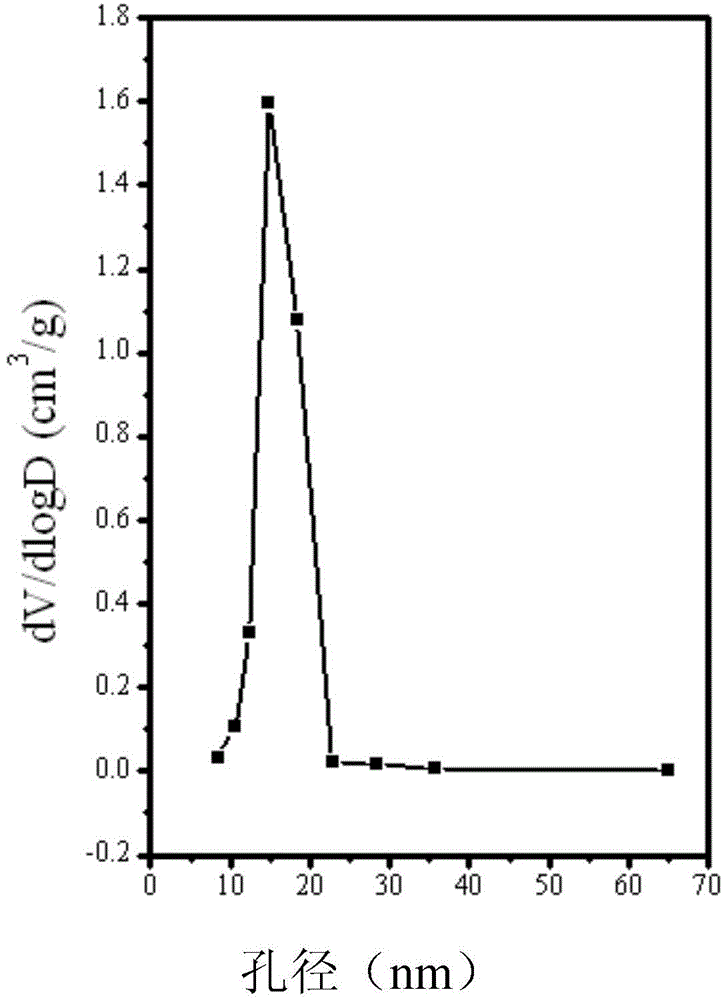

[0019] Example 1: Using polyethylene glycol-6000 as a template, DMSO as a solvent, and 180°C to synthesize CM-TiO 2 .

[0020] Add 1.0g of polyethylene glycol-6000 into 35g of dimethyl sulfoxide solvent and slightly heat to dissolve, then add 3.5g of n-butyl titanate, and at the same time add 1ml of water to promote the hydrolysis of the titanium source. After stirring and reacting at room temperature for 6 hours, the The reaction mixture was transferred into a stainless steel reaction kettle, and subjected to hydrothermal treatment at 180°C for 24 hours, then the reaction kettle was taken out, cooled, filtered with suction, washed and dried to obtain the primary product, which had a high degree of crystallinity. The primary product is calcined under air conditions at 500°C to obtain a mesoporous titanium dioxide material with open channels and highly crystallized framework. , the specific surface area of the material reaches 60m 2 / g, pore diameter 18 nanometers, pore vol...

Embodiment 2

[0021] Example 2: Using polyethylene glycol-600 as a template, DMSO as a solvent, and 140°C to synthesize CM-TiO 2 .

[0022] Add 2.0g of polyethylene glycol-6000 into 90g of dimethyl sulfoxide solvent and slightly heat to dissolve, then add 3.0g of n-butyl titanate, and at the same time add about 1ml of water to promote the hydrolysis of the titanium source, stir and react at room temperature for 6 hours, Transfer the reaction mixture into a stainless steel reaction kettle, conduct hydrothermal treatment at 140°C for 24 hours, take out the reaction kettle, cool, filter with suction, wash, and dry to obtain the primary product, which has a high degree of crystallinity. The primary product is calcined under air conditions at 600°C to obtain a mesoporous titanium dioxide material with open pores and highly crystallized framework. The specific surface area of the material reaches 120m 2 / g, pore diameter 4 nanometers, pore volume 0.23cm 3 / g.

Embodiment 3

[0023] Example 3: Using polyethylene glycol-2000 as a template, DMSO as a solvent, and 220°C to synthesize CM-TiO 2 .

[0024] Add 2.0g of polyethylene glycol-6000 into 90g of dimethyl sulfoxide solvent and slightly heat to dissolve, then add 3.0g of n-butyl titanate, and at the same time add about 1ml of water to promote the hydrolysis of the titanium source, stir and react at room temperature for 6 hours, Transfer the reaction mixture into a stainless steel reaction kettle, conduct hydrothermal treatment at 220°C for 24 hours, take out the reaction kettle, cool, filter with suction, wash, and dry to obtain the primary product, which has a high degree of crystallinity. The primary product is calcined under air conditions at 1000°C to obtain a mesoporous titanium dioxide material with open pores and a highly crystallized framework. The specific surface area of the material reaches 50m 2 / g, pore diameter 20 nanometers, pore volume 0.1cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com