Method for preparing adipic acid polyester polyol by utilizing recycled alcohol

A technology for adipic acid polyester and alcohol recovery, which is applied in the direction of chemical recovery, can solve the problems of difficult water removal, refining and purification costs, high energy consumption, and large consumption, and achieves low production costs, high heating efficiency, The effect of environmentally friendly and low energy consumption reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

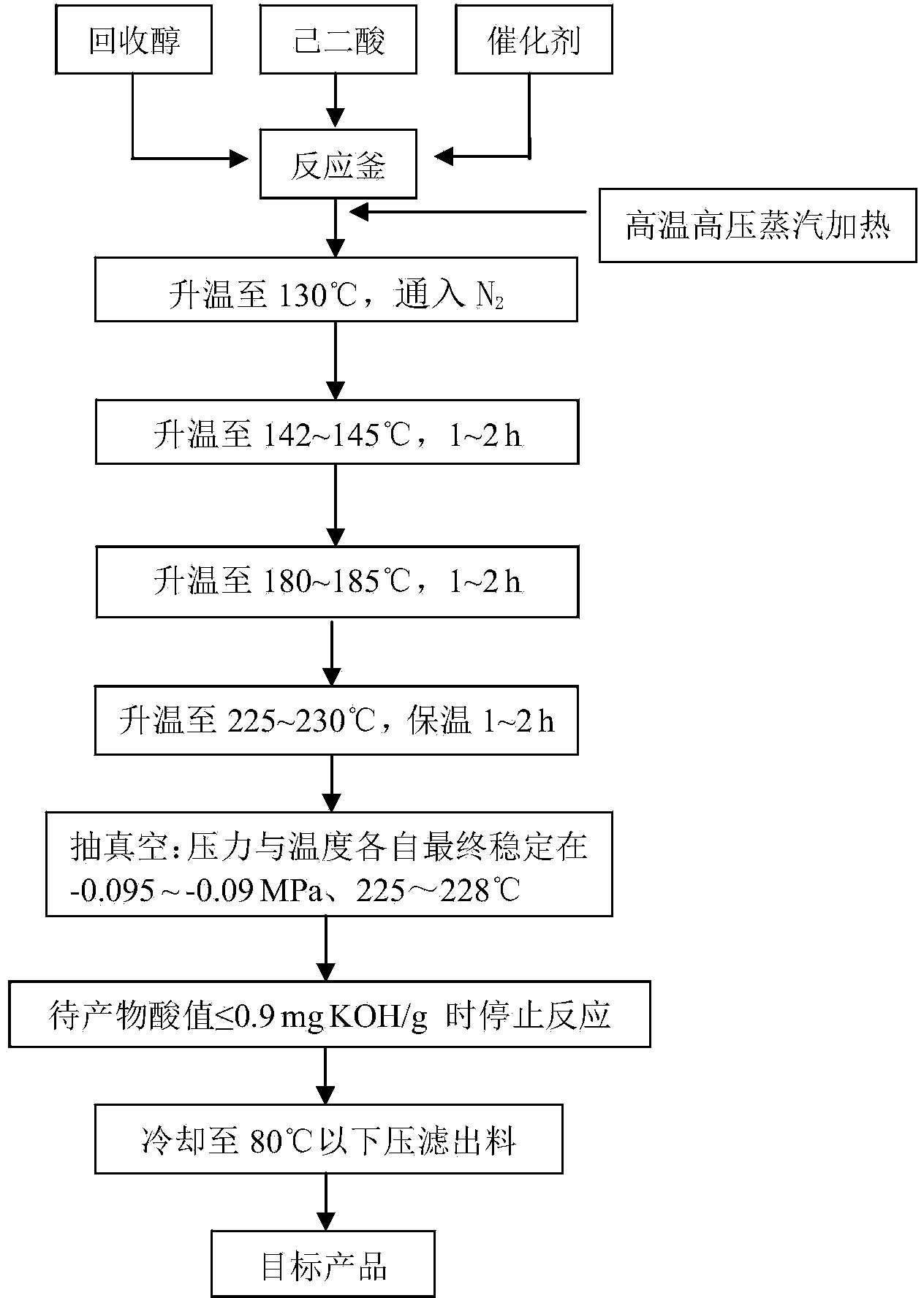

[0026] 1): Put 50Kg of recycled solar wafer cutting fluid (hydroxyl value 500mg KOH / g), 50Kg of recycled 1,2-propanediol (content 95%), 100Kg of adipic acid and 25g of monobutyltin oxide into the polyester reaction at one time in the kettle

[0027] 2): Using high temperature and high pressure steam heating method, after the temperature rises to 130°C, N 2 , continue to heat up to 142°C, and react for 2h;

[0028] 3): pass into N 2 Use as protective gas and keep it uninterrupted, continue to heat up to 180°C, and react for 2 hours;

[0029] 4): heat up to 225°C, keep warm for 2 hours;

[0030] 5): Start vacuuming, the pressure and temperature are finally stabilized at -0.09MPa and 225°C, and the reaction is stopped when the acid value of the product is ≤0.9mg KOH / g.

[0031] 6): Cool to below 80°C and filter the material to obtain viscous transparent adipic acid polyester polyol (hydroxyl value 75mg KOH / g, acid value 0.8mg KOH / g, moisture 0.03%, chroma 230 Hazen).

Embodiment 2

[0033] 1): Put 68Kg of recycled solar wafer cutting fluid (hydroxyl value 598mg KOH / g), 35Kg of recycled 1,2-propanediol (90% content), 100Kg of adipic acid and 61g of monobutyltin oxide into polyester at one time In the reactor;

[0034] 2): Using high temperature and high pressure steam heating method, after the temperature rises to 130°C, N 2 , continue to heat up to 145°C, and react for 1h;

[0035] 3): pass into N 2 Use as protective gas and keep it uninterrupted, continue to heat up to 185°C, and react for 1h;

[0036] 4): Heat up to 230°C and keep warm for 1 hour;

[0037] 5): Start vacuuming, the pressure and temperature are finally stabilized at -0.095MPa and 225°C, and the reaction is stopped when the acid value of the product is ≤0.9mg KOH / g.

[0038] 6): Cool down to below 80°C and press filter to get viscous transparent adipic acid polyester polyol (hydroxyl value 40mg KOH / g, acid value 0.7mg KOH / g, moisture 0.02%, chroma 270 Hazen).

Embodiment 3

[0040] 1): Add 80Kg of recycled solar wafer cutting fluid (hydroxyl value 750mg KOH / g), 30Kg of recycled 1,2-propanediol (content 90%), 100Kg of adipic acid and 32g of monobutyltin oxide into polyester at one time In the reactor;

[0041] 2): Using high temperature and high pressure steam heating method, after the temperature rises to 130°C, N 2 , continue to heat up to 144°C, and react for 1.5h;

[0042] 3): pass into N 2 Use as protective gas and keep it uninterrupted, continue to heat up to 182°C, and react for 1.5h;

[0043] 4): heat up to 228°C, keep warm for 1.5h;

[0044] 5): Start vacuuming, the pressure and temperature are finally stabilized at -0.095MPa and 226°C, and the reaction is stopped when the acid value of the product is ≤0.9mg KOH / g.

[0045] 6): Cool down to below 80°C and filter the material to obtain viscous transparent adipic acid polyester polyol (hydroxyl value 126mg KOH / g, acid value 0.8mg KOH / g, moisture 0.03%, chroma 300 Hazen).

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com