Micro-emulsified diesel oil

A micro-emulsion and diesel technology, applied in the petroleum field, can solve the problems of difficulty in re-starting, large particle size of water droplets, instability, etc., and achieve the effects of high practical value, good effect and stable system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

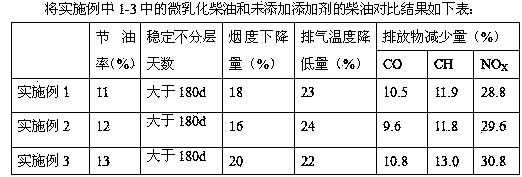

Embodiment 1

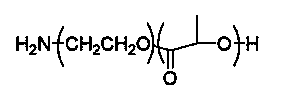

[0035] Synthesis of amino-terminated ethylene oxide-polylactic acid copolymer:

[0036] Under an inert gas atmosphere, first add 4 parts of lactide into tank A, then inject 5 parts of tetrahydrofuran, 1 part of potassium hexamethyldisilazide and 1.8 parts of ethylene oxide into tank B at 10°C, Stir the reaction in tank B at 0°C for 10 h, then quickly pour the reaction solution into tank A, stir and react at 20°C for 3 h, and finally terminate the reaction with degassed anhydrous methanol, and finally vacuum-dry at 40°C for 24 h to obtain a milky white viscous Thick product.

[0037] Microemulsion diesel blending:

[0038] After mixing the prepared amino-terminated oxirane-polylactic acid copolymer and other components according to the metering, under the condition of 70°C, stir for 40 minutes at a speed of 100 rpm in a vertical stirring tank to obtain this product Invention of micro-emulsion diesel.

[0039] The specific components are as follows:

[0040] 0# Diesel 80 par...

Embodiment 2

[0049] Synthesis of amino-terminated ethylene oxide-polylactic acid copolymer:

[0050] Under an inert gas atmosphere, first add 6 parts of lactide into tank A, then inject 10 parts of tetrahydrofuran, 2 parts of potassium hexamethyldisilazide and 1 part of ethylene oxide into tank B at 0°C, Stir the reaction in tank B at 20°C for 20h, then quickly pour the reaction liquid into tank A, stir and react at 25°C for 2h, and finally terminate the reaction with degassed anhydrous methanol. Finally, vacuum-dry at 50°C for 20 h to obtain a milky white viscous product.

[0051] Microemulsion diesel blending:

[0052] After mixing the prepared amino-terminated ethylene oxide-polylactic acid copolymer and other components according to the metering, under the condition of 30 ℃, stir in a vertical stirring tank at a speed of 300 rpm for 30 minutes to obtain this product Invention of micro-emulsion diesel.

[0053] The specific components are as follows:

[0054] 0# Diesel 60 parts

[...

Embodiment 3

[0063] Synthesis of amino-terminated ethylene oxide-polylactic acid copolymer:

[0064] Under an inert gas atmosphere, firstly add 5g of lactide (lactic acid dimer) into tank A, then sequentially add 8 parts of tetrahydrofuran, 1.5 parts of potassium hexamethyldisilazide and 1.0 parts of ethylene oxide at 5°C Pour alkanes into tank B, stir and react in tank B at 10°C for 15h, then quickly pour the reaction solution into tank A, stir and react at 22°C for 2.5h, and finally terminate the reaction with degassed anhydrous methanol. Finally, vacuum-dry at 45°C for 22 hours to obtain a milky white viscous product.

[0065] Microemulsion diesel blending:

[0066] After mixing the prepared amino-terminated ethylene oxide-polylactic acid copolymer and other components according to the metering, under the condition of 50 ℃, stir in a vertical stirring tank at a speed of 200 rpm for 35 minutes to obtain this product Invention of micro-emulsion diesel.

[0067] The specific components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com