Smoke dust removing and waste heat recovering integrated box of boiler

A technology of waste heat recovery and boiler flue gas, applied in lighting and heating equipment, chemical instruments and methods, combustion methods, etc., can solve the problems of polluting the environment, energy loss, increasing production costs, etc., and achieves the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

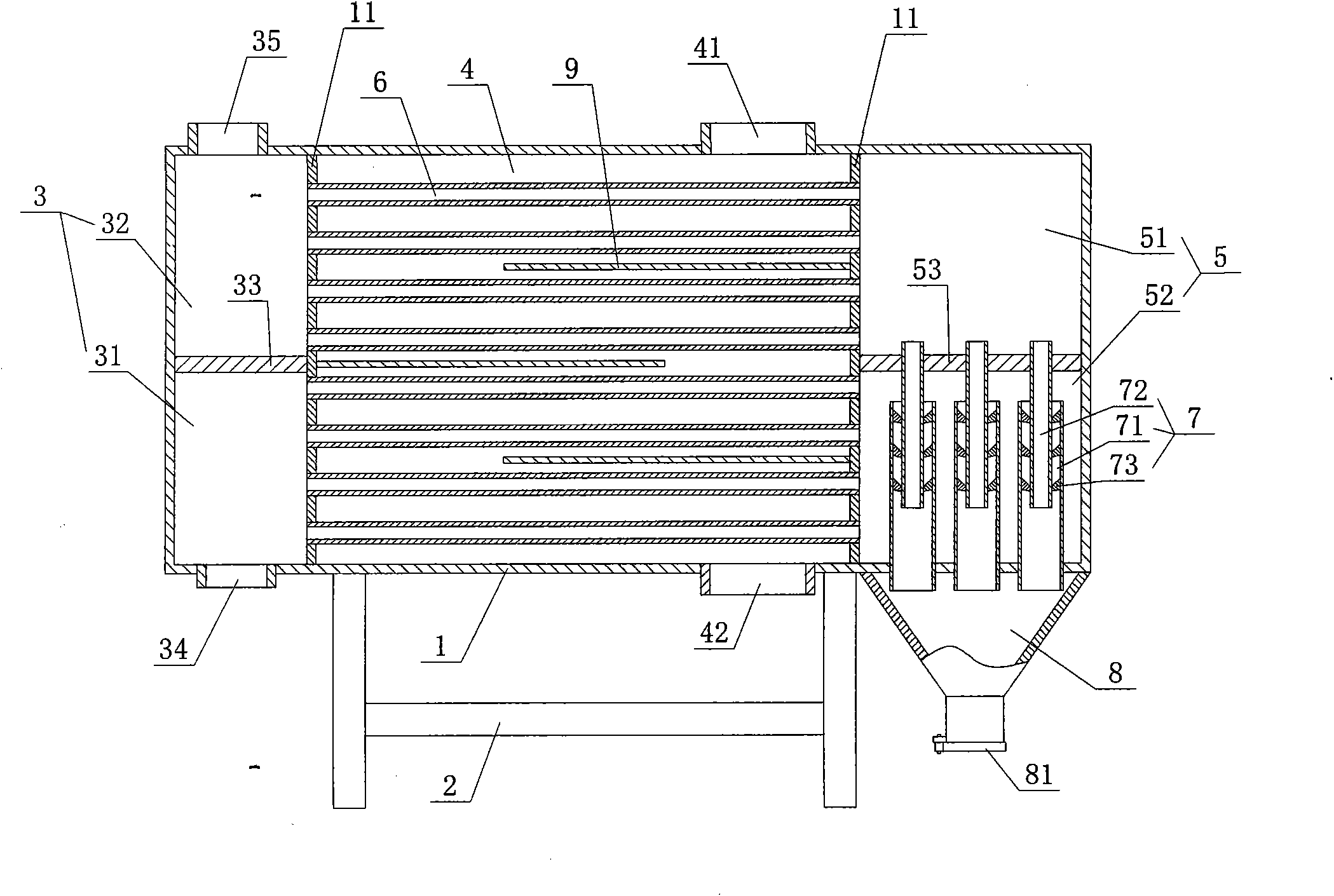

[0011] Referring to the accompanying drawings, the boiler flue gas dust removal and waste heat recovery integrated box of the present invention includes a box body 1 and a bracket 2 connected to the bottom of the box body 1. The inner cavity of the box body 1 is divided into flue gas chamber 3, heat exchange chamber 4 and dust removal chamber 5, the flue gas chamber 3 is provided with a first transverse partition 33 that separates it into a smoke chamber 31 and a smoke chamber 32, and the dust chamber 5 is provided with a partition that separates it into The second transverse partition 53 of the upper dust chamber 51 and the lower dust chamber 52, a plurality of heat exchange tubes 6 are arranged at intervals in the heat exchange chamber 4, and a part of the heat exchange tubes 6 communicates with the smoke chamber 31 and the lower dust chamber 52, The other part connects the upper dust chamber 51 and the smoke outlet chamber 32; the smoke inlet chamber 31 is provided with a sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com