High temperature solar energy thermal absorber

A solar heat absorber, high temperature technology, applied in the direction of solar heat collector, solar thermal energy, solar thermal power generation, etc., can solve the problem of reduced thermal insulation and sealing performance of optical window, shortened service life of heat absorber, deformation of inlet flange, etc. problems, to achieve the effect of being conducive to sealing installation, prolonging service life and reducing air leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

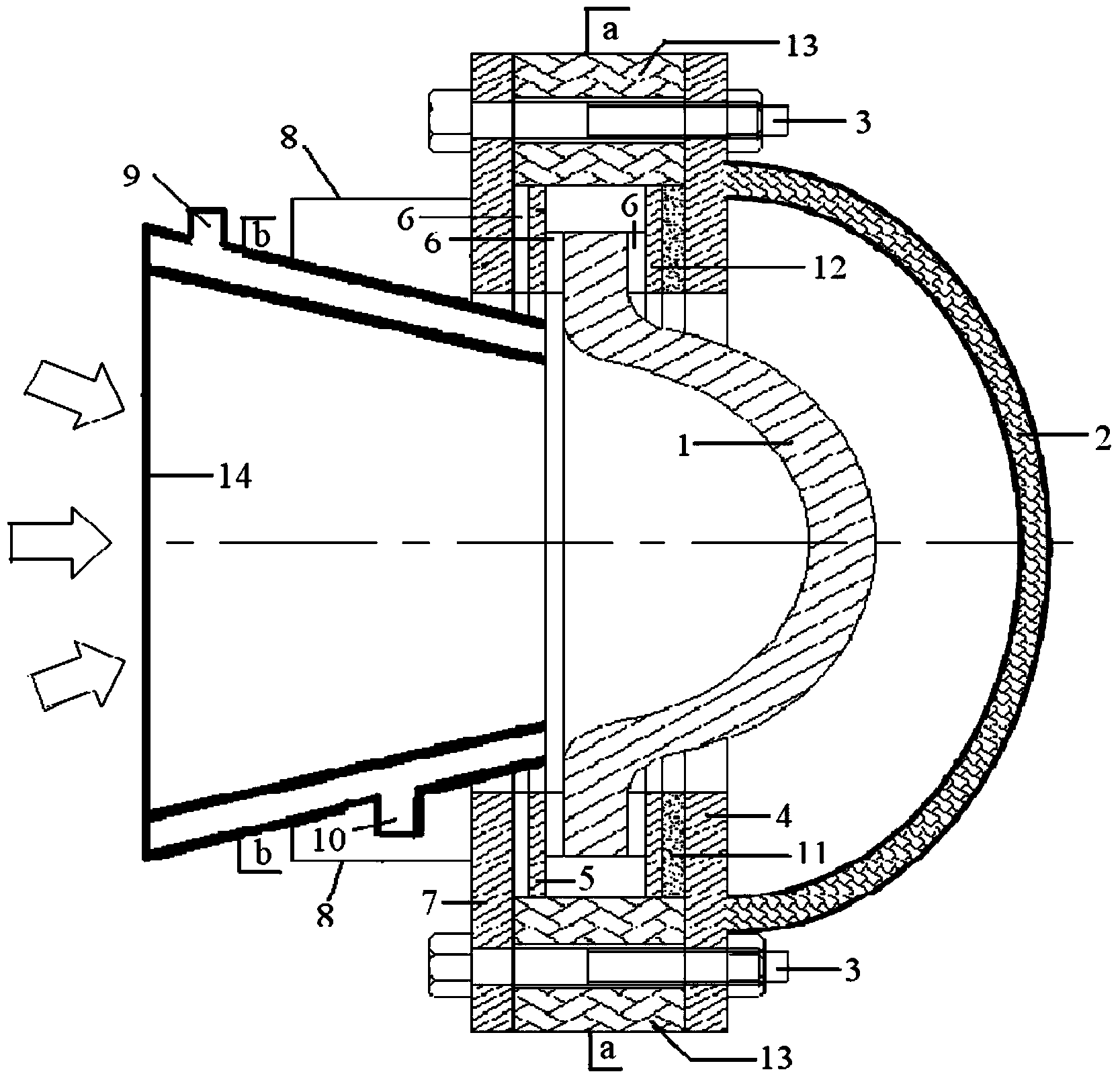

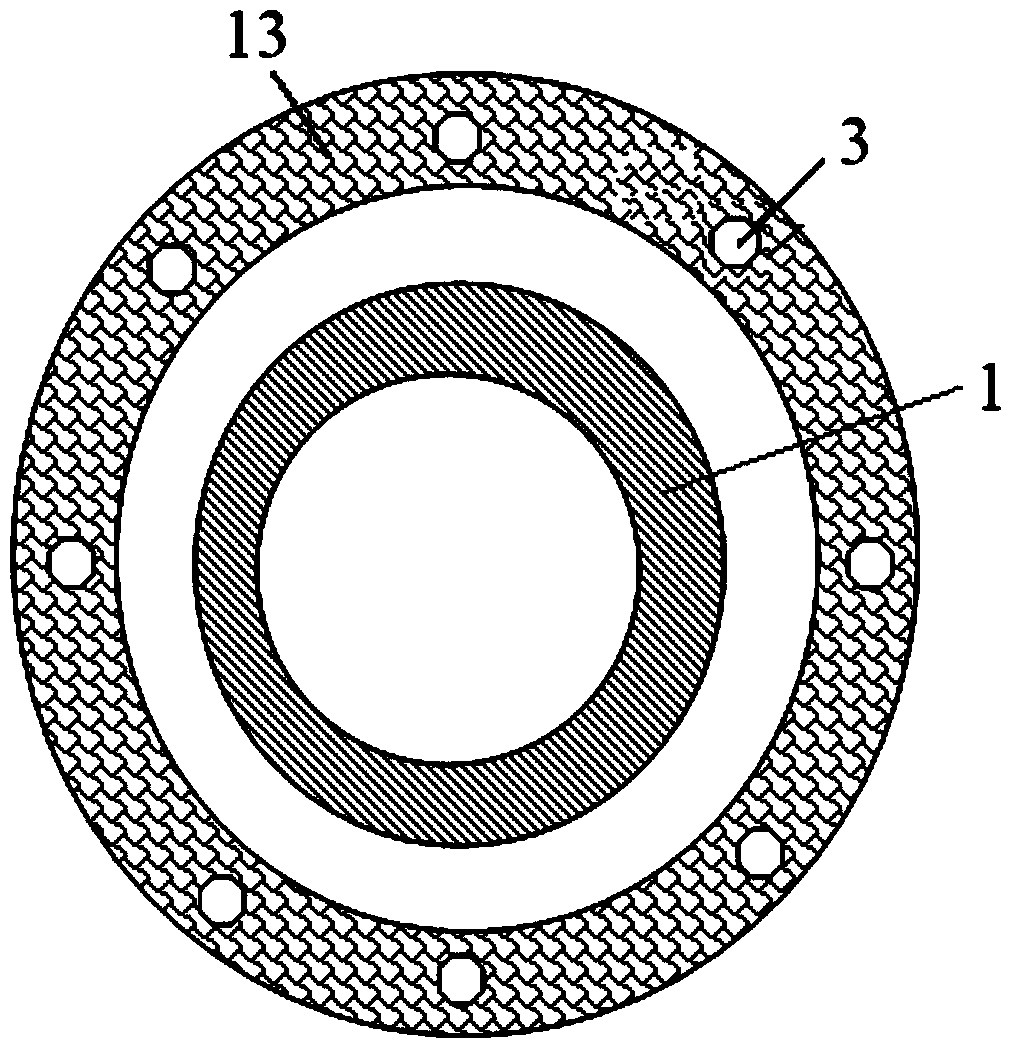

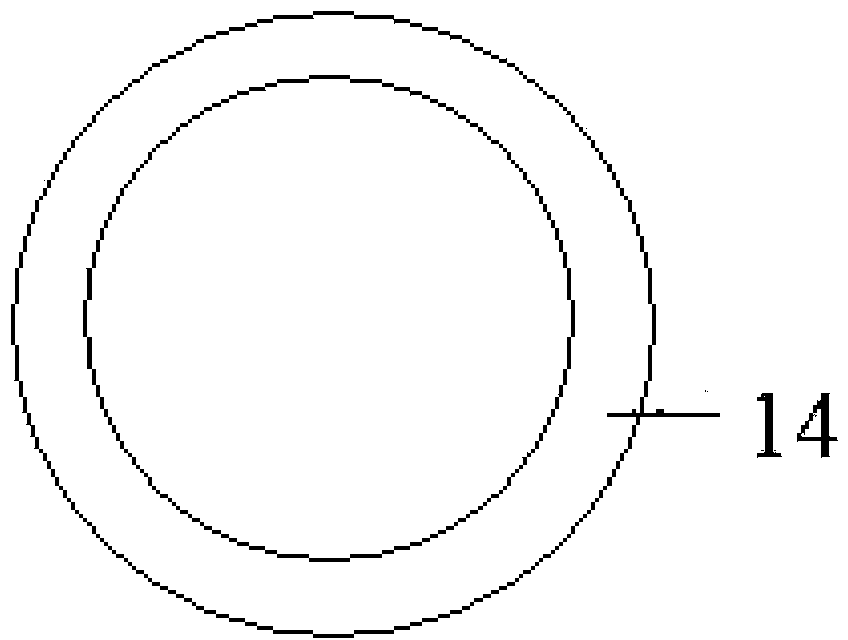

[0022] Specific implementation mode one: combine Figure 1-3 , a high-temperature solar heat absorber of the present embodiment, which includes a heat-absorbing cavity 2 and a semi-ellipsoidal optical window 1, and is characterized in that it also includes a high-temperature-resistant resin glue 6, an annular inner metal sheet 12, and an annular outer metal sheet 5 , annular ceramic fiber mat 11, annular inner flange 4, annular outer flange 7, bolts 3, annular graphite gasket 13, frustum-shaped water-cooled target stage 14 and target stage support 8; semi-ellipsoidal optical window 1 has an annular platform , the semi-ellipsoid shape of the semi-ellipsoidal optical window 1 is smoothly transitioned to the annular platform, and the annular inner metal sheet 12 and the annular outer metal sheet 5 are respectively connected to the semi-ellipsoidal optical window with the annular platform through the high temperature resistant resin glue 6. The upper and lower planes of the annula...

specific Embodiment approach 2

[0037] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the materials of the annular inner flange 4 and the annular outer flange 7 are both steel. Others are the same as the first embodiment.

specific Embodiment approach 3

[0038] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that: the materials of the annular inner metal sheet 12 and the annular outer metal sheet 5 are both steel. Others are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com