A flat tube counterflow heat exchanger

A counter-current heat exchange and heat exchanger technology, applied in the direction of heat exchanger type, indirect heat exchanger, heat exchange equipment, etc., can solve the problem that the distribution of liquid fluid in the evaporator is not uniform, consumes too much circulating pump power, and fin exchange Short thermal flow and other problems, to achieve the effect of obvious field synergy, eliminate the effect of the entrance section, and increase the average temperature difference of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

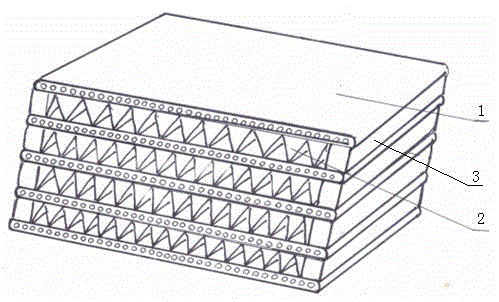

[0041] refer to figure 1 , this embodiment includes flat tubes 1 and fins 2, the two sides of the fins 2 are equipped with sealing strips 3, the flat tubes 1 and the fins 2 are alternately arranged in parallel, and the flow path direction of the flat tubes 1 Parallel to the flow channel direction of the fins 2 on the outside of the flat tube to form a counter-current heat exchange.

[0042] In this embodiment, the heat exchange capacity on both sides can be better balanced, and the length of each small channel of the flat tube is consistent, and the resistance is equal, so that the coordination of the flow velocity field and the temperature gradient field is very ideal.

Embodiment 2

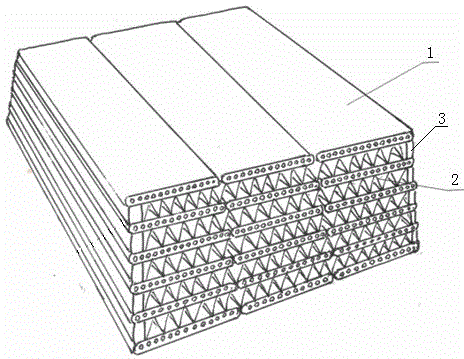

[0044] refer to figure 2 , this embodiment includes flat tubes 1 and fins 2, the two sides of the fins 2 are equipped with sealing strips 3, and on the same plane, there are three flat tubes 1, which are connected to each other to form wide flat tubes, so The wide flat tubes and the fins 2 are alternately arranged in parallel, and the flow channel direction of the wide flat tubes is parallel to the flow channel direction of the fins, forming countercurrent heat exchange.

[0045] Of course, the number of flat tubes 1 can also be other numbers, and they are connected to each other to form different wide flat tubes, which will not be repeated here. Utilizing this embodiment, the limitation of the manufacturing process due to the width of the flat tube can be overcome, and the purpose of large-scale heat exchange can be achieved.

Embodiment 3

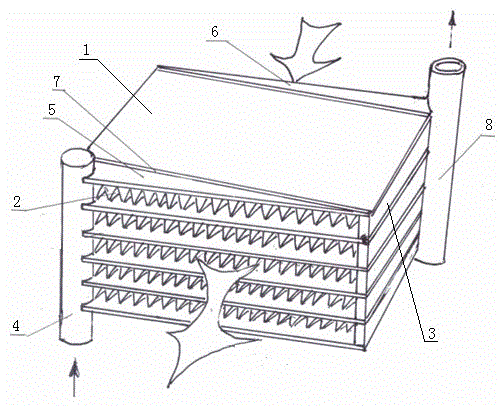

[0047] refer to image 3, this embodiment includes flat tubes 1, fins 2, and headers. Sealing strips 3 are installed on both sides of the fins 2. The flat tubes 1 and fins 2 are alternately arranged in parallel. The flat tubes 1 The flow channel direction is parallel to the flow channel direction of the fins 2 on the outside of the flat tube, forming countercurrent heat exchange; On the opposite corners of the heater, the direction of the fluid channel that goes in and out from the bottom is formed. The distribution header 4 is connected to the distribution flat tubes 5 of each layer, and the distribution flat tubes 5 of each layer are connected to the flat tubes of the corresponding layer through the flat tube connecting device 7. 1 connection, the confluence header 8 is connected to the confluence flat tubes 6 of each layer, and each layer of confluence flat tubes 6 is connected to the flat tubes 1 of the corresponding layer through the flat tube connecting device, forming a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com