An integrated power supply servo control system

A servo control system and controller technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of large volume of power board control part, large waste of electric resources, poor anti-interference ability, etc. Achieve the effects of convenient expansion, wire saving and strong anti-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

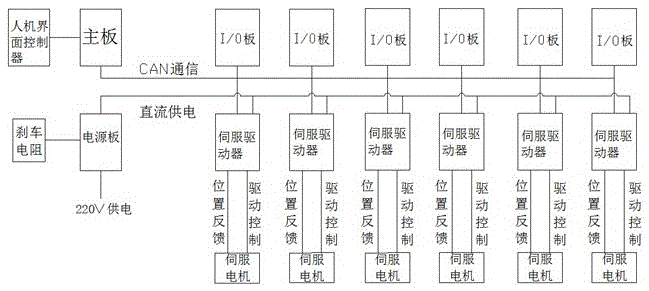

[0015] In this example, refer to figure 1 As shown, an integrated power supply servo control system includes a man-machine interface controller, a main board connected with the man-machine interface controller, an I / O board connected with the main board, a servo driver connected with the main board, and a The power board connected to the servo driver, the servo motor, and the braking resistor connected to the power board, the connection communication between the main board and the I / O board is CAN communication, and the main board is also connected to the servo driver through CAN communication; The power supply board provides DC power supply for the servo driver; the man-machine interface controller is touch screen type and button type.

[0016] Wherein, more than one servo driver can be installed, and more than one servo driver is connected in series to realize line saving, simple wiring, and reduce production cost; the servo driver receives the work sent by the main board th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com