Method for efficiently preparing positive and negative electrode paste

A technology of electrode slurry and positive electrode slurry, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as product quality differences, unreasonable coordination, and restrictions on lithium battery production efficiency, and achieve improved performance, high capacity, and long life. The effect of cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

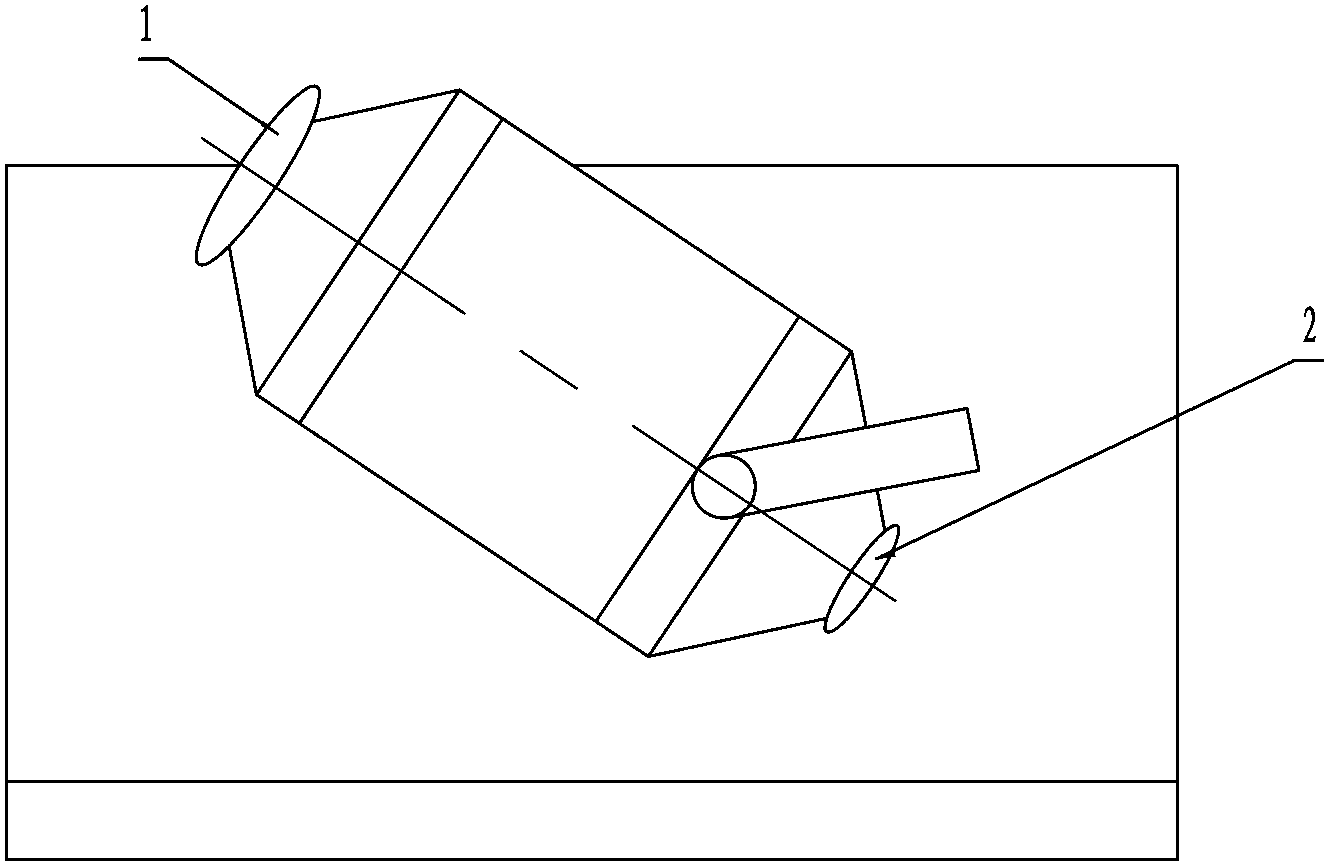

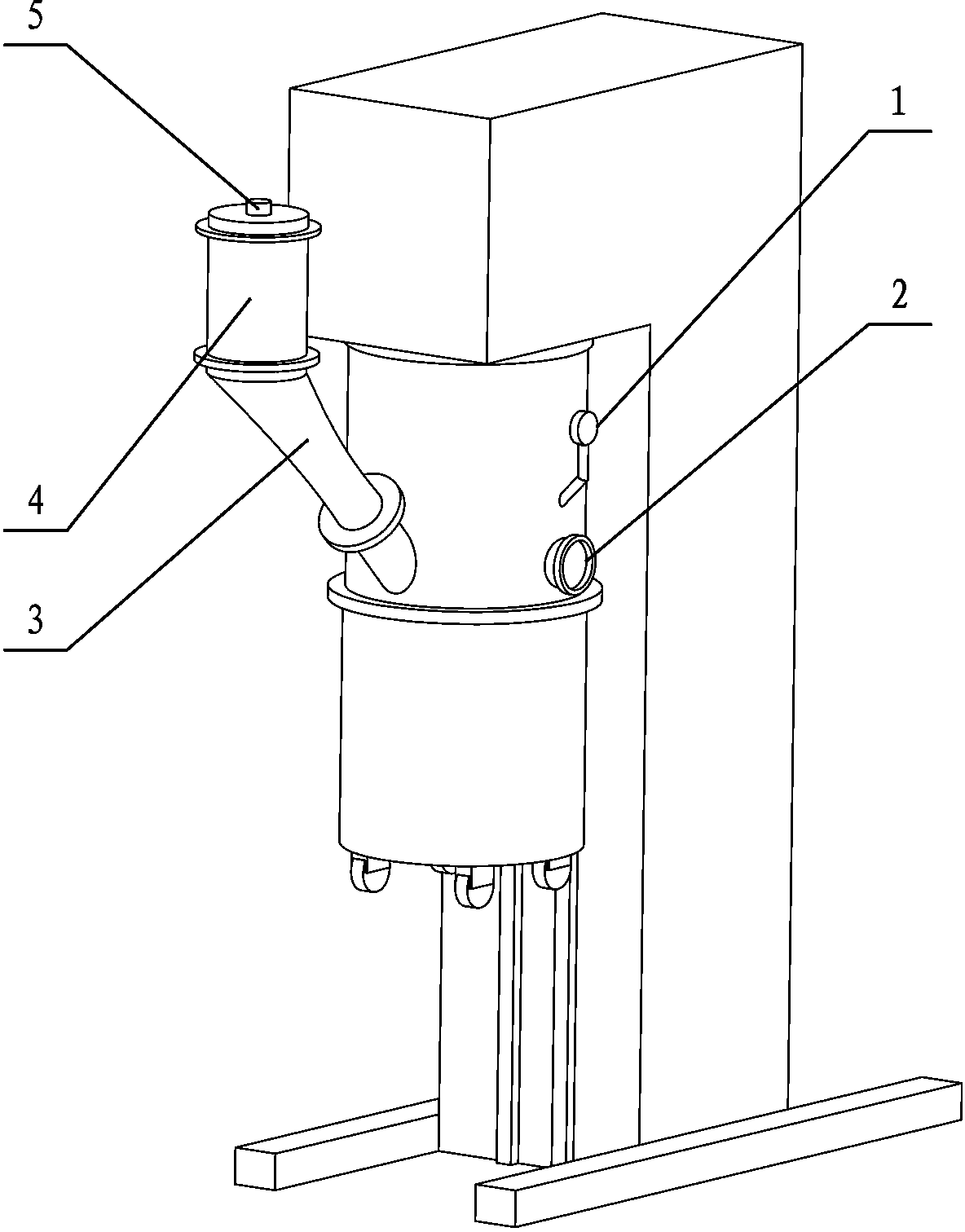

Method used

Image

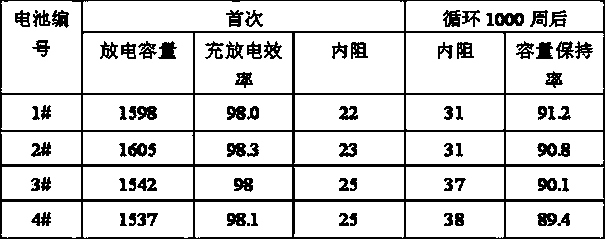

Examples

Embodiment 1

[0015] Positive electrode slurry preparation: lithium iron phosphate LiFePO 4 The active material, carbon black SP and conductive graphite KS-6 conductive agent are mixed in a three-dimensional mixer. The mixing time is 2 hours and the frequency is set to 30Hz. Tetrafluoroethylene (PVDF) was added into the nitrogen methyl pyrrolidone (NMP) solvent to stir and dissolve. The automatic feeding mixer had a rotation speed of 500 rpm and a revolution speed of 10 rpm. After stirring for 0.5 hours, vacuumize. The vacuum value is -0.05Mpa, and the rotation and revolution speeds are increased to 1500 rpm and 25 rpm respectively, and the stirring time is 2 hours. Slowly add the uniformly mixed positive electrode powder into the automatic feeding mixer along the feeding port. In the mixing tank, the addition is completed within 30 minutes. At the same time, the rotation and revolution speed of the mixer are adjusted to 500 rpm and the revolution speed is 10 rpm, that is, stirring while fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com