Preparation method of reflective film for laser resonator cavity mirror

A resonant cavity and reflective film technology, which is applied in the field of reflective film preparation, can solve problems such as narrowing of the working area, low reflectivity of the reflective film, and increased difficulty in plating, so as to increase reflectivity, increase output light intensity, and improve Effect of Laser Beam Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

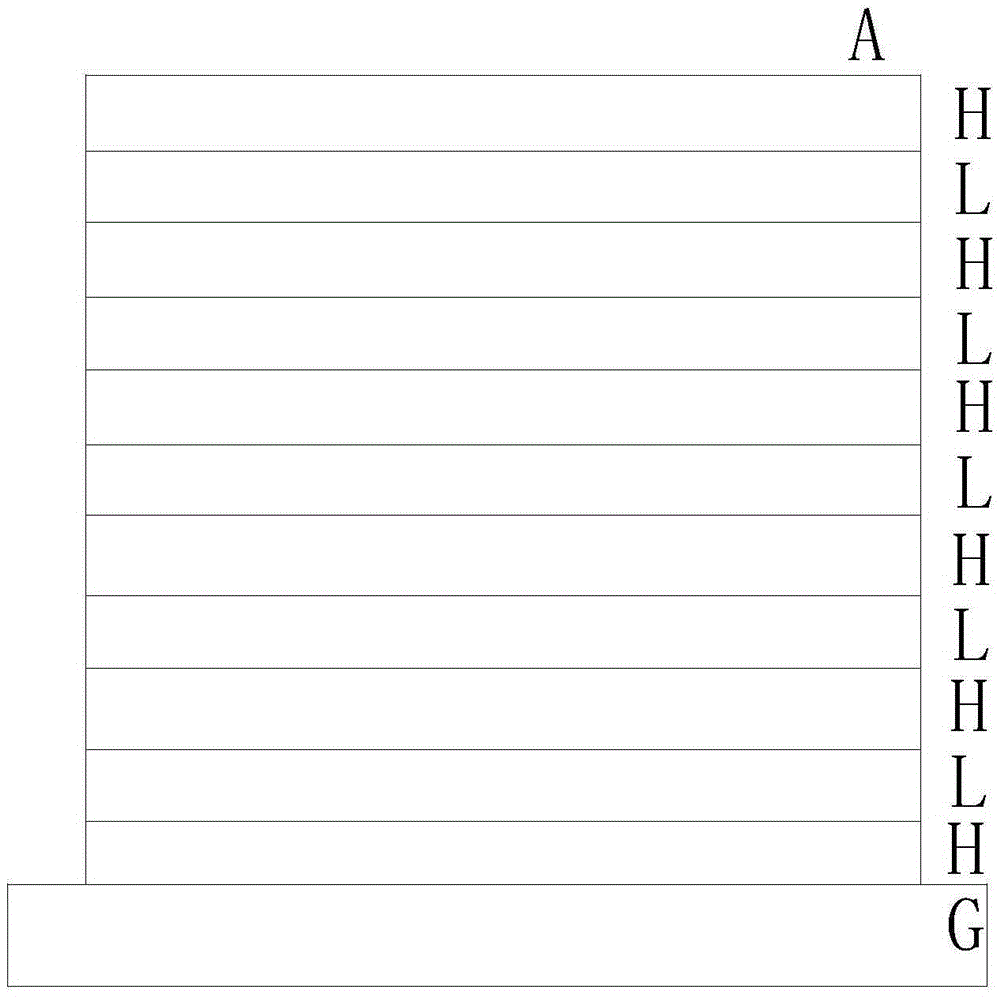

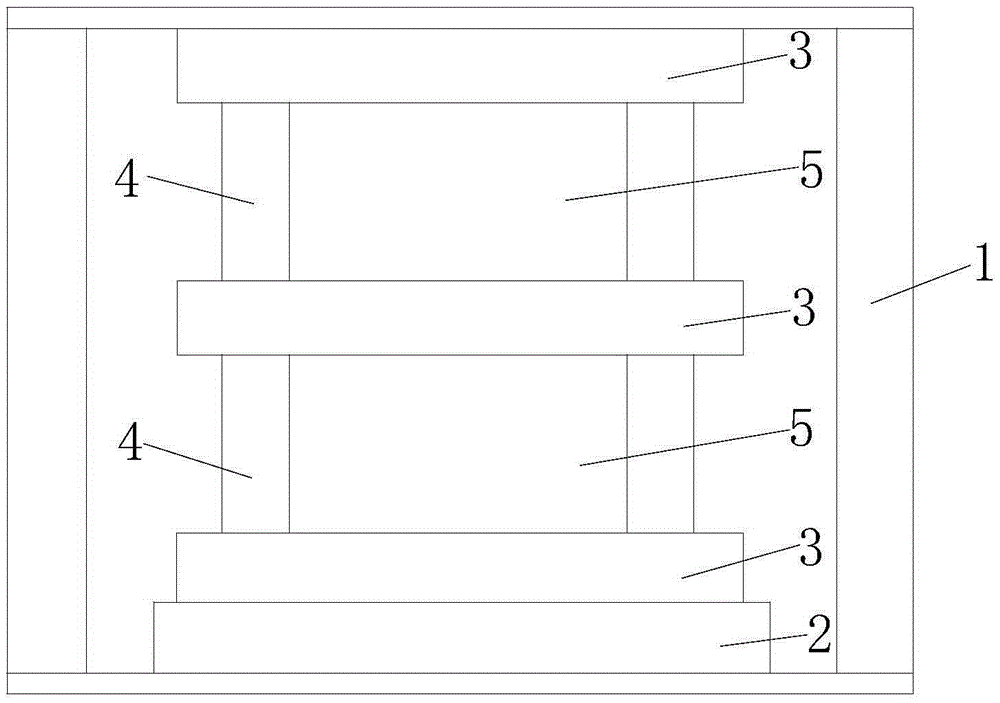

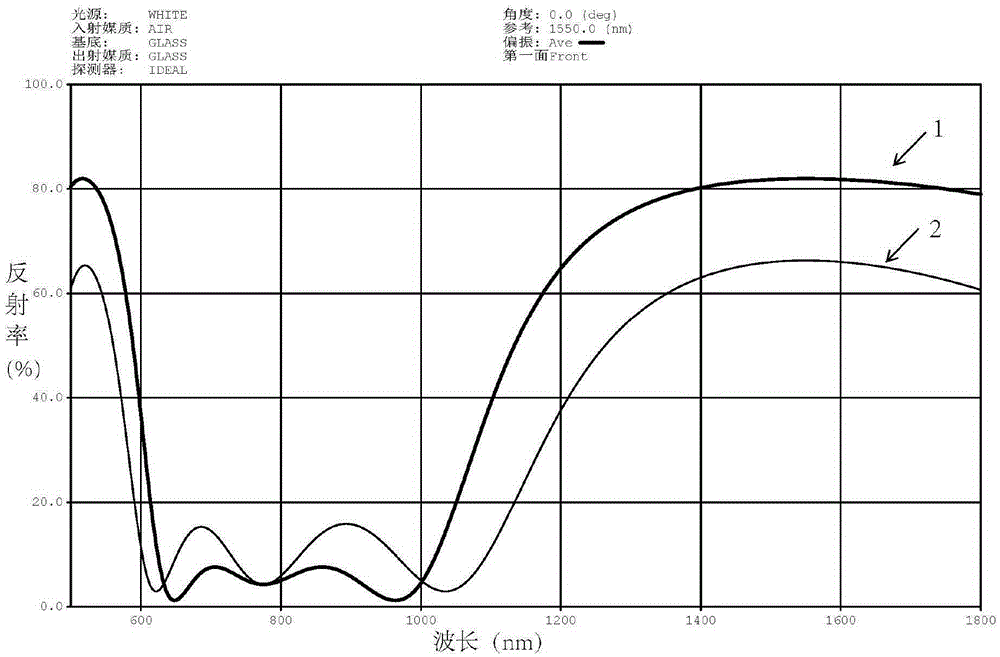

[0028] In this embodiment, the reflective film used for the laser resonator cavity mirror is a five-layer film structure, that is, three high-refractive-index film layers 3 and two vacuum layers 5, and the optical thickness of the high-refractive-index film layer 3 is λ 0 / 4, the optical thickness of the vacuum layer 5 is λ 0 / 4, λ 0 For the wavelength of incident light, the high refractive index film layer 3 uses TiO 2 It is fabricated, the incident medium is air, the substrate 2 is ordinary glass, and the working window is 1550 nm; the traditional five-layer reflective film for laser resonator cavity mirror includes a substrate, and the upper surface of the substrate is sequentially stacked with high refractive index Film layer, low refractive index film layer, high refractive index film layer, low refractive index film layer, high refractive index film layer, high refractive index film layer using TiO 2 The low refractive index film is made of SiO 2 Made, the incident me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com