Method for solving short circuit of signal through hole and packaging bonding pad

A signal via hole and soldering technology, which is applied to printed circuit components, electrical connection printed components, etc., can solve problems such as PCB board burnout, open flame burning, function debugging, etc., to ensure quality, avoid short circuits, and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

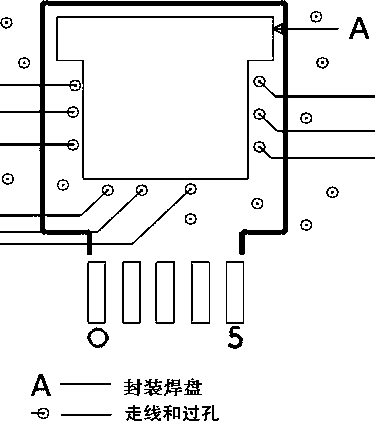

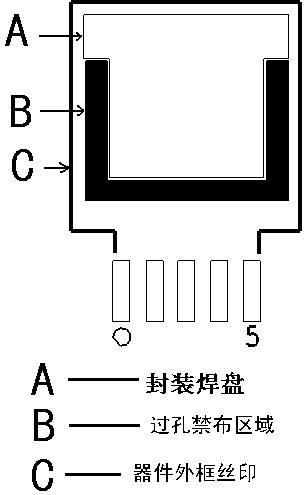

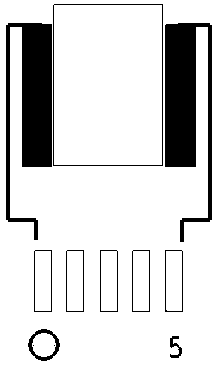

[0015] In this embodiment, the LDO device is taken as an example, such as figure 2 , 3 , the large pad at the bottom of the LDO is larger than its package pad, and a no-distribution area is set around the package pad to ensure that when there are traces and vias in this area, there will be a DRC error reminder, or it will not be possible directly. Holes are punched, so designers can avoid punching holes here. In this way, the risk of short circuit between the package pad and the via hole after soldering can be prevented, such as Figure 4 .

[0016] Using this method can improve the reliability of the product: the forbidden area can prevent the PCB from punching wrong signal lines and vias around the packaging pads of electronic components during the design process, and ensure that signal lines o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com