Thermoset and thermoplastic fibers and preparation thereof by uv curing

A technology of thermosetting and thermoplastic polymers, applied in the direction of fiber chemical characteristics, fiber processing, medical preparations of non-active ingredients, etc., can solve problems such as inability to melt and reshape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

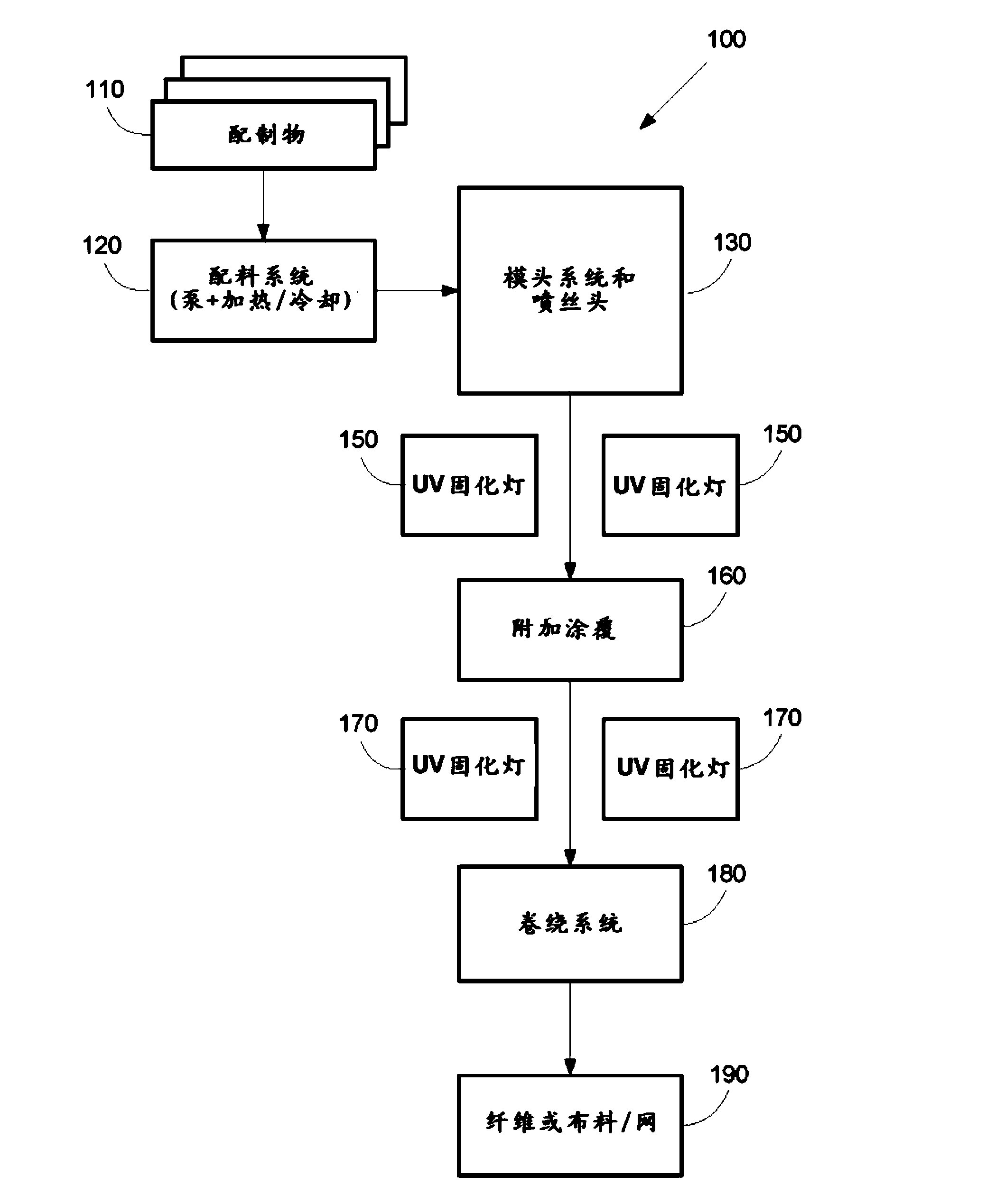

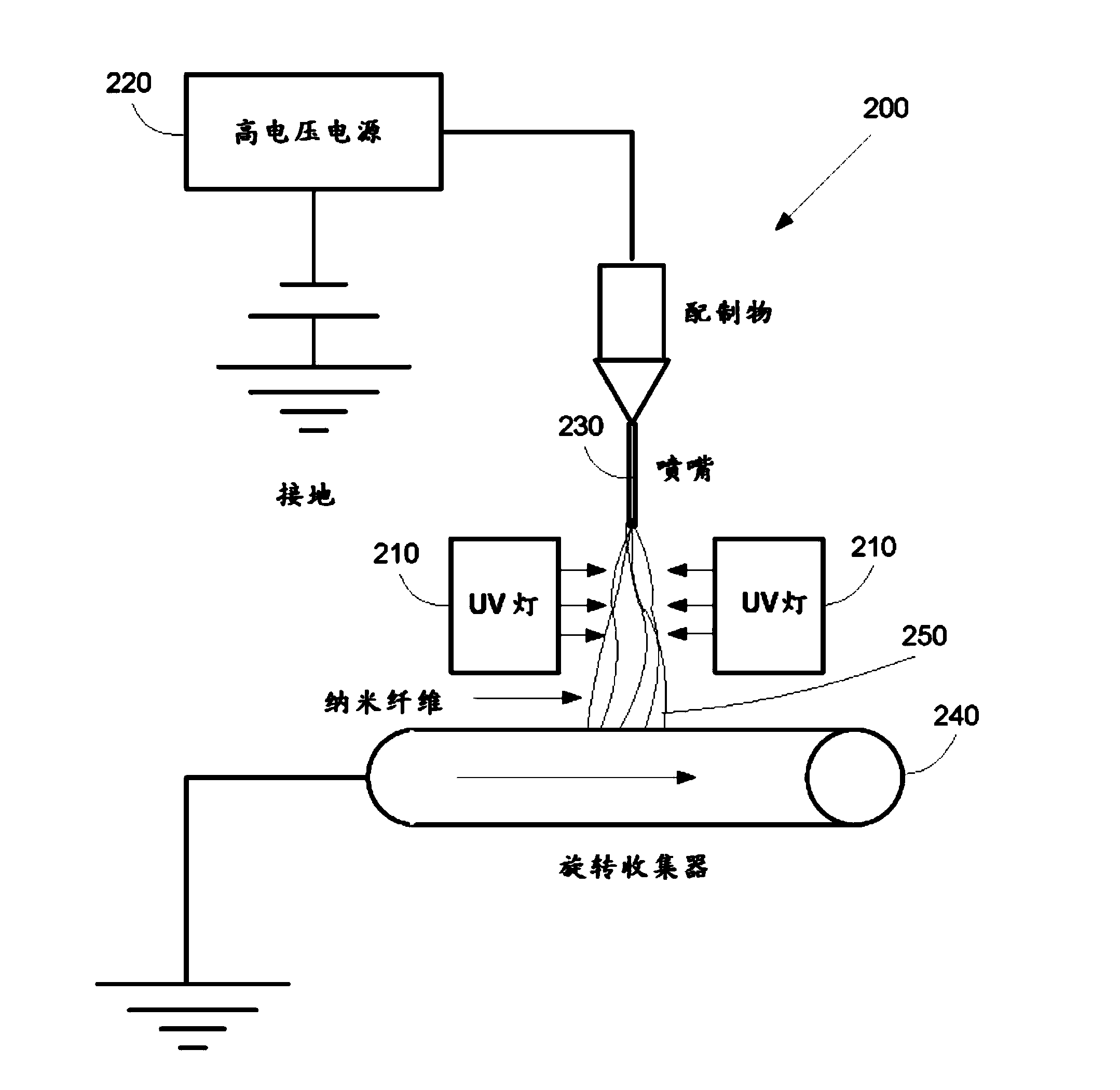

[0121] Process for preparing the polymer fibers of the present invention

[0122] For the preparation of thermoset fibers the following compositions were prepared

[0123]

[0124] All ingredients of Example 1 were mixed and heated slightly (approximately 50° C.) until clear; a single phase solution was obtained. After cooling the solution to room temperature, the viscosity of the solution at room temperature was 620 cPs.

[0125] The cooled solution was poured into a flask, which was attached to a die with a single hole having a diameter of 400 microns. A pressure equal to 1.2 atmospheres was applied to the reaction mixture, which resulted in the formation of a liquid jet, which poured through the orifice. Three UV lamps (MHL-250, USHIO) were arranged vertically just below the die hole. Due to the presence of UV radiation, the reaction mixture polymerizes immediately to form solid thermoset fibers. The fibers were collected with a twin-head winder at a speed of 250 m...

Embodiment 2

[0128] Process for preparing the polymer fibers of the present invention

[0129]

[0130] The cooled solution was poured into a flask, which was attached to a die with a single hole having a diameter of 400 microns. A pressure equal to 1.2 atmospheres was applied to the reaction mixture, which resulted in the formation of a liquid jet, which poured through the orifice. Six UV lamps (MHL-250, USHIO) were arranged vertically just below the die hole. Due to the presence of UV radiation, the reaction mixture polymerizes immediately to form solid thermoset fibers. The fibers were collected with a twin-head winder at a speed of 250 m / min.

Embodiment 3

[0132] Process for preparing the polymer fibers of the present invention

[0133] For the preparation of thermoset fibers the following compositions were prepared

[0134]

[0135] The cooled solution was poured into a flask, which was attached to a die with a single hole having a diameter of 400 microns. A pressure equal to 1.2 atmospheres was applied to the reaction mixture, which resulted in the formation of a liquid jet, which poured through the orifice. Six UV lamps (MHL-250, USHIO) were arranged vertically just below the die hole. Due to the presence of UV radiation, the reaction mixture polymerizes immediately to form solid thermoset fibers. The fibers were collected with a twin-head winder at a speed of 250 m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com