Processing method for full-nutrition sweetend roll from persimmon

A processing method and technology of fruit peel, applied in the confectionary industry, confectionery, food science, etc., can solve the problems of indigestibility, etc., and achieve the effect of easy digestion, mechanized production of process flow, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

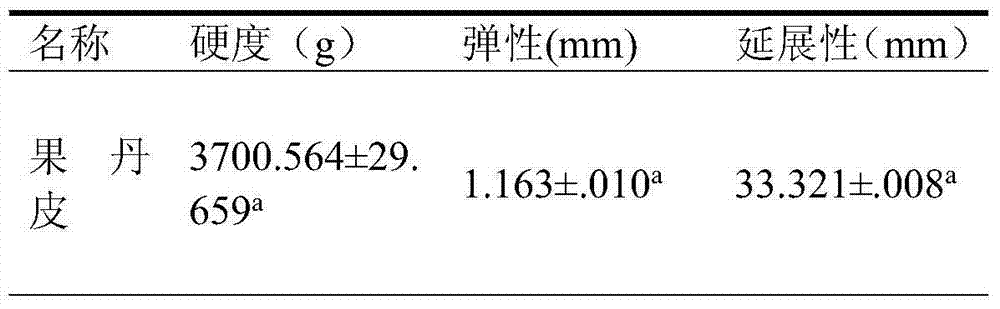

Image

Examples

Embodiment 1

[0032] A kind of processing method of persimmon full-nutrition fruit peel, its steps are as follows:

[0033] (1) Selection: The maturity of persimmons is 9 minutes;

[0034] (2) Cleaning: Wash the persimmons mentioned in (1) with clean water to remove surface impurities and dust;

[0035] (3) Remove astringency: Pass the persimmons mentioned in (2) evenly through the cleaning tank filled with 65-75% ethanol, 3-5% acetic acid (acetic acid can break the membrane), and 0.8% sodium glutamate aqueous solution through the conveyor belt. Sodium glutamate can keep the meat fresh, crisp and fragrant), and put it flat in the plastic basket with holes, stack it layer by layer, and quickly wrap the stacked persimmons in a large plastic tent to form an airtight environment, and remove the astringency for 4 days ;

[0036] (4) Squeeze and separate: Squeeze and break the persimmons after (3) deastringency to separate the stalk, peel and pulp, and filter out the peel and stalk through a 40...

Embodiment 2

[0049] A kind of processing method of persimmon full-nutrition fruit peel, its steps are as follows:

[0050] (1) Selection: The maturity of persimmons is 7 minutes;

[0051] (2) Cleaning: Wash the persimmons mentioned in (1) with clean water to remove surface impurities and dust;

[0052] (3) Remove astringency: Pass the persimmons mentioned in (2) evenly through the cleaning tank filled with 65-75% ethanol, 3-5% acetic acid (acetic acid can break the membrane), and 0.8% sodium glutamate aqueous solution through the conveyor belt. Sodium glutamate can keep the meat fresh, crisp and fragrant), and put it flat in the plastic basket with holes, stack it layer by layer, and quickly wrap the stacked persimmons in a large plastic tent to form an airtight environment, and remove the astringency for 4 days ;

[0053] (4) Squeeze and separate: Squeeze and break the persimmons after (3) deastringency to separate the stalk, peel and pulp, and filter out the peel and stalk through a 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com