Moisture type CC cream composition and preparation method thereof

A composition and water-discharging technology, which is applied in the direction of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., can solve the problems of greasy skin, clogged pores, and unsatisfactory skin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Water type CC cream (I)

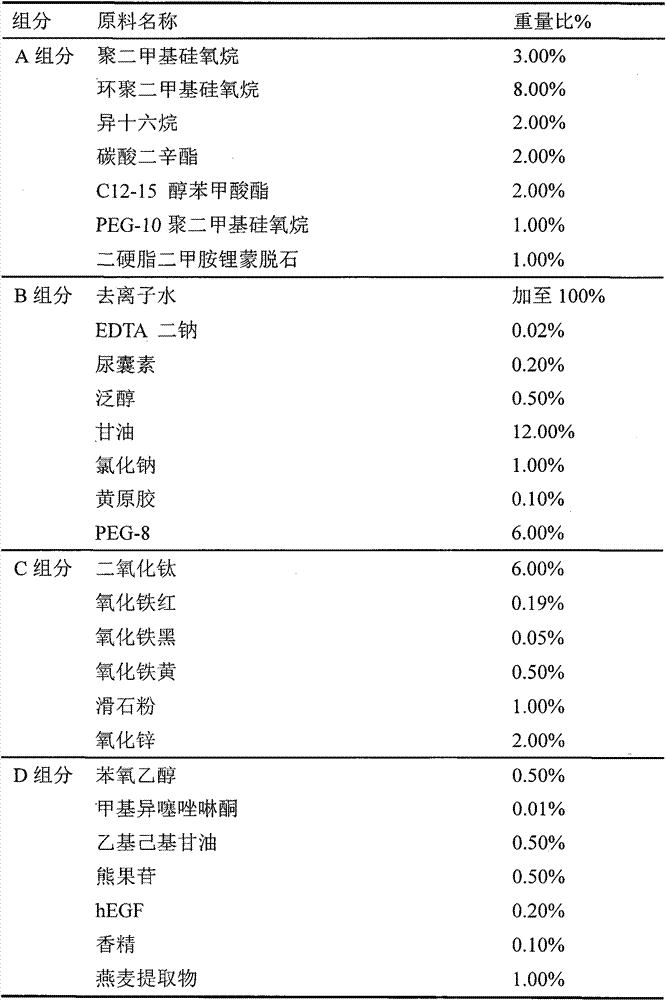

[0025] The formula is shown in Table 1.

[0026] Table 1

[0027]

[0028] The preparation method is as follows:

[0029] (1) Grind the C component with an appropriate amount of A component grease through a colloid mill, so that the powder is completely infiltrated and put into

[0030] Emulsifying pot.

[0031] (2) Put the remaining A component into the emulsifying pot, stir and disperse evenly, as the oil phase.

[0032] (3) Dissolve and disperse the B component materials uniformly at room temperature, and set aside.

[0033] (4) Add B component slowly and uniformly into the oil phase under stirring conditions, which takes 1.0 to 3.0 minutes. After the addition is complete, emulsify for 0.5 to 5.0 minutes at a homogenizing speed of 1000 to 6000 rpm.

[0034] (5) Cool down to 40°C and add component D to the emulsifying pot and stir evenly.

[0035] (6) Stir evenly, evacuate, cool to 35°C and discharge.

Embodiment 2

[0036] Example 2 Water type CC cream (II)

[0037] The formula is shown in Table 2.

[0038] Table 2

[0039]

[0040]

[0041] The preparation method is as follows:

[0042] (1) Grind the C component with an appropriate amount of A component grease through a colloid mill, and put the powder into the emulsification pot after being completely infiltrated.

[0043] (2) Put the remaining A component into the emulsifying pot, stir and disperse evenly, as the oil phase.

[0044] (3) Dissolve and disperse the B component materials uniformly at room temperature, and set aside.

[0045] (4) Add B component slowly and uniformly into the oil phase under stirring conditions, which takes 1.0 to 3.0 minutes. After the addition is complete, emulsify for 0.5 to 5.0 minutes at a homogenizing speed of 1000 to 6000 rpm.

[0046] (5) Cool down to 40°C and add component D to the emulsifying pot and stir evenly.

[0047] (6) Stir evenly, evacuate, cool to 35°C and discharge.

Embodiment 3

[0048] Example 3 Water type CC cream (III)

[0049] The formula is shown in Table 3.

[0050] table 3

[0051]

[0052]

[0053] The preparation method is as follows:

[0054] (1) Grind the C component with an appropriate amount of A component grease through a colloid mill, and put the powder into the emulsification pot after being completely infiltrated.

[0055] (2) Put the remaining A component into the emulsifying pot, stir and disperse evenly, as the oil phase.

[0056] (3) Dissolve and disperse the B component materials uniformly at room temperature, and set aside.

[0057] (4) Add B component slowly and uniformly into the oil phase under stirring conditions, which takes 1.0 to 3.0 minutes. After the addition is complete, emulsify for 0.5 to 5.0 minutes at a homogenization speed of 1000 to 6000 rpm.

[0058] (5) Cool down to 40°C and add component D to the emulsifying pot and stir evenly.

[0059] (6) Stir evenly, evacuate, cool to 35°C and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com