Membrane element, membrane block, and membrane separation system

A membrane element and branching technology, which is applied in the field of membrane blocks, membrane separation systems and membrane elements, can solve the problems of filter membrane clogging times, uneven pressure loss of filter membrane, and increased burden of air diffuser, etc., and achieve uniform pressure loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

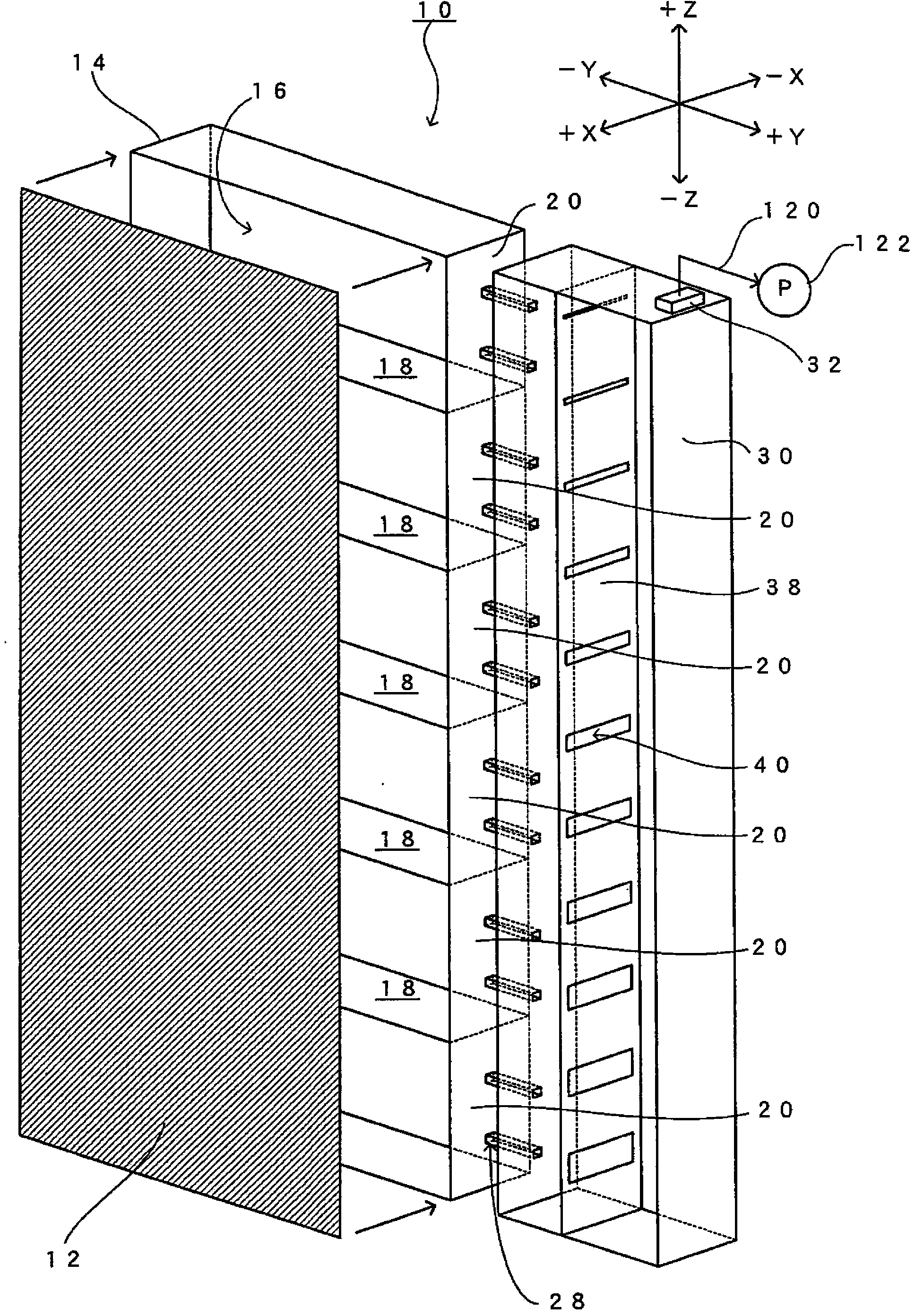

[0038] Hereinafter, the present invention will be specifically described using the illustrated embodiments. However, unless otherwise specified, the components, types, combinations, shapes, and relative arrangements thereof described in this embodiment do not limit the scope of the present invention thereto, but are merely examples for illustration. In addition, in the drawings and the description below, it is assumed that the X axis (horizontal direction), the Y axis (horizontal direction), and the Z axis (vertical direction) are perpendicular to each other.

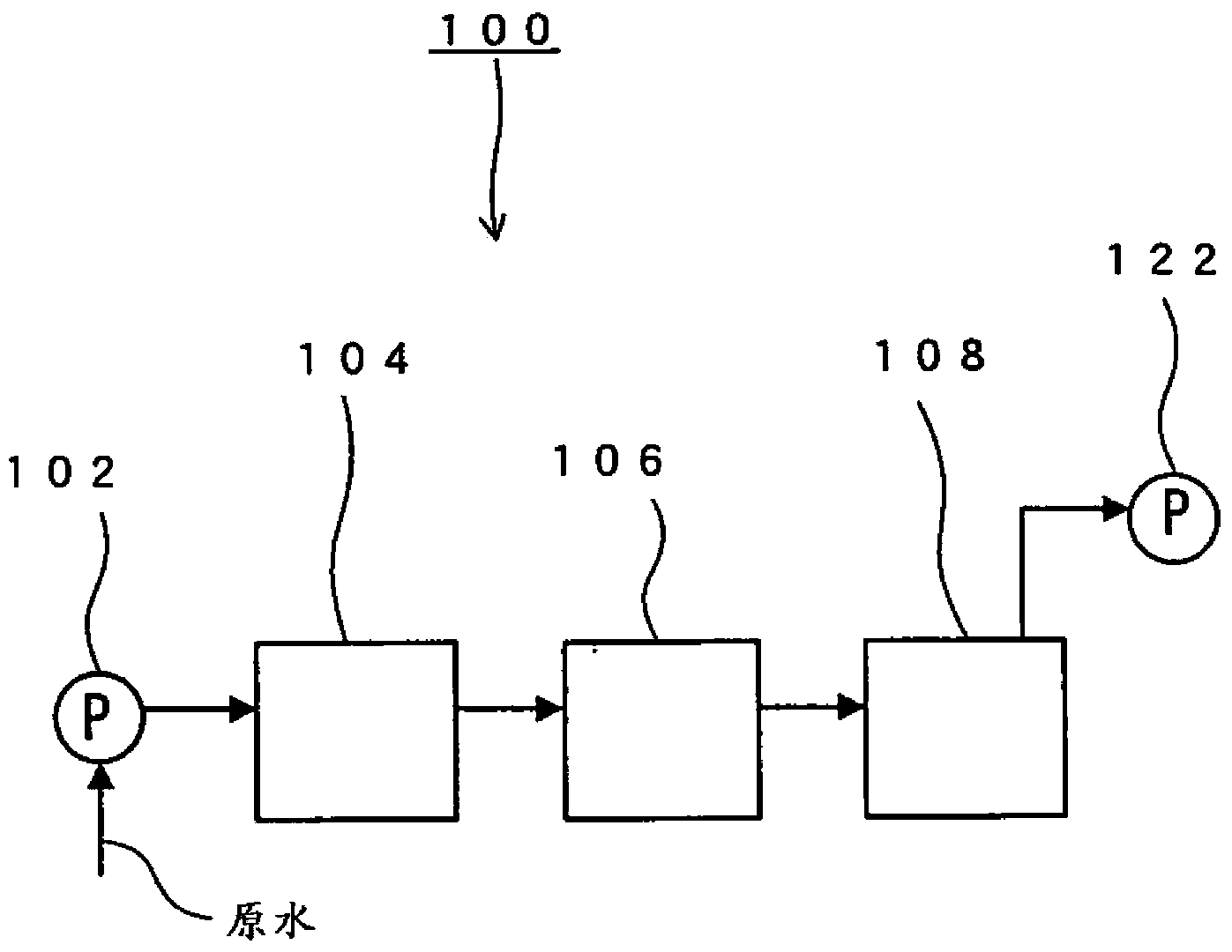

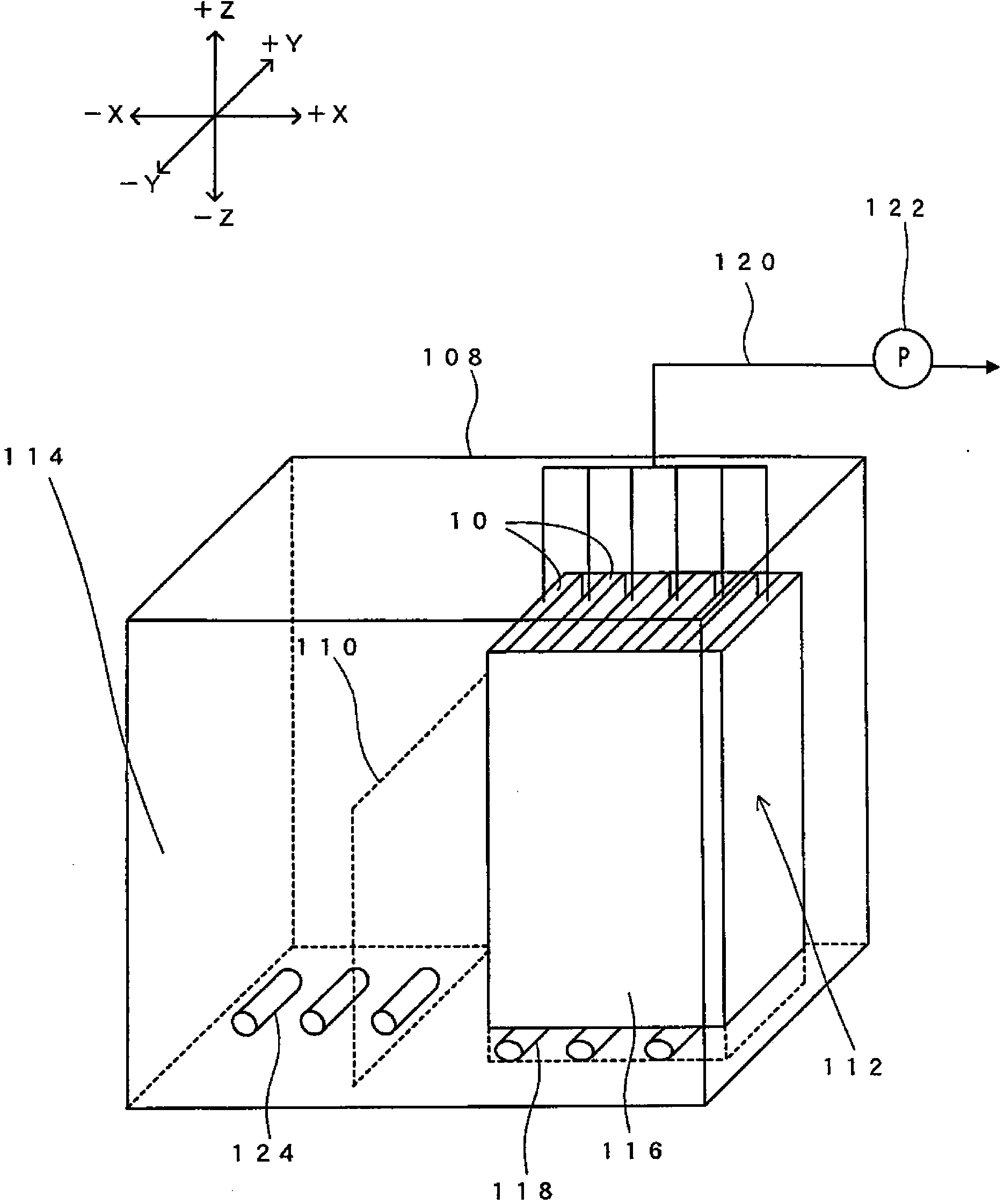

[0039] figure 2A block diagram showing the membrane separation system of this embodiment. The membrane separation system 100 of the present embodiment has a structure including: an anaerobic tank 104 in which raw water is supplied by a raw water pump 102 and phosphorus is temporarily released from activated sludge; and an anaerobic tank 106 in which denitrification reaction of raw water is performed. and a reaction t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com