Crude oil coagulated pipe plug removal device and plug removal method with plug removal device

A technology of pipeline condenser and block remover, which is applied in chemical instruments and methods, cleaning methods and utensils, cleaning hollow objects, etc., can solve the problems of complicated blocking removal process, long construction time, structural damage of oil pipelines, etc. The blocking process is simple, the construction time is short, and the risk of environmental pollution is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

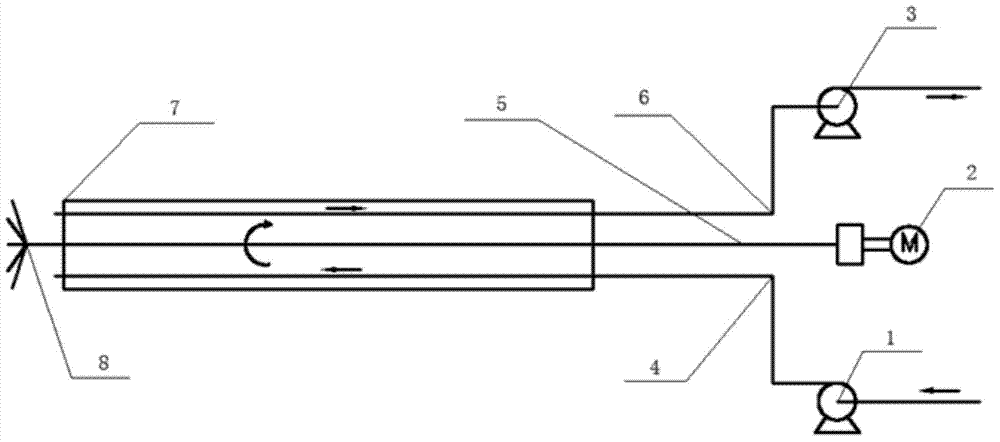

[0031] Specific Embodiment 1: A crude oil pipeline coagulation pipe unblocking device in this embodiment includes a liquid injection pump 1, a motor 2, a liquid suction pump 3, a casing 7, a liquid inlet pipe 4, a liquid outlet pipe 6, and an agitator drive shaft 5 and the agitator stirring head 8, the liquid inlet pipe 4, the liquid outlet pipe 6 and the agitator drive shaft 5 are set in the casing 7, the liquid inlet pipe 4 is connected with the injection pump 1, and the agitator transmission The shaft 5 is connected with the motor 2 , the liquid outlet pipe 6 is connected with the pump 3 , and the drive shaft 5 of the agitator is connected with the stirring head 8 of the agitator.

[0032] Further: the infusion pump 1 is made of stainless steel.

[0033] Further: the casing 7 is made of a rubber hose reinforced with stainless steel wire.

[0034] Further: The liquid inlet pipe 4 is made of a rubber hose reinforced with stainless steel wire.

[0035] Further: Motor 2 adopt...

specific Embodiment approach 2

[0040] Specific implementation mode two: the specific steps of the crude oil pipeline coagulation tube deblocking method of the present embodiment are:

[0041] Step 1: Determine the position of the condensation pipe section and determine the available openings near the pipe;

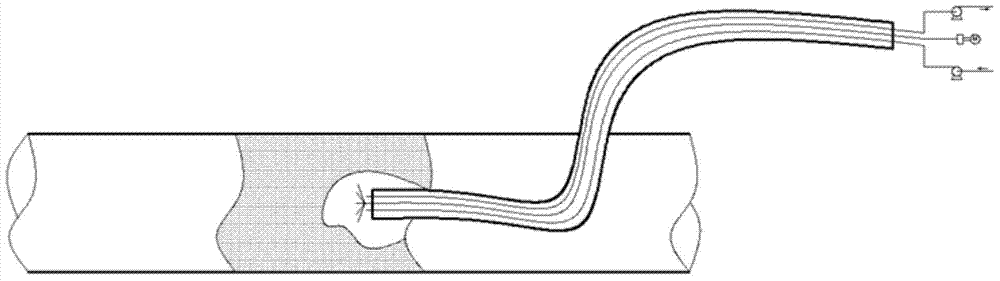

[0042] Step 2: Insert the casing 7 of the plug remover into the available opening, so that the stirring head 8 of the agitator touches the solidified crude oil;

[0043] Step 3: Turn on the motor 2, drive the agitator transmission shaft 5, drive the agitator stirring head 8, and crush the solidified crude oil;

[0044] Step 4: Prepare the blocking solution, turn on the injection pump 1, pour the blocking solution into the solidified crude oil section through the liquid inlet pipe 4, and use the blocking solution to heat the solidified crude oil and broken particles;

[0045] Step 5: Turn on the liquid suction pump 3, and pump out the mixed liquid formed by the deblocking liquid after heat exchange and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com