A fully automatic solder dipping machine

A fully automatic, dip-soldering technology, applied in tin feeding devices, welding equipment, auxiliary devices, etc., can solve the problems of unstable process, rapid cooling of molten tin, high requirements for operators' skills and physical fitness, and overcome the problems of manual operation. , to ensure the production process, to avoid the effect of wasting resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

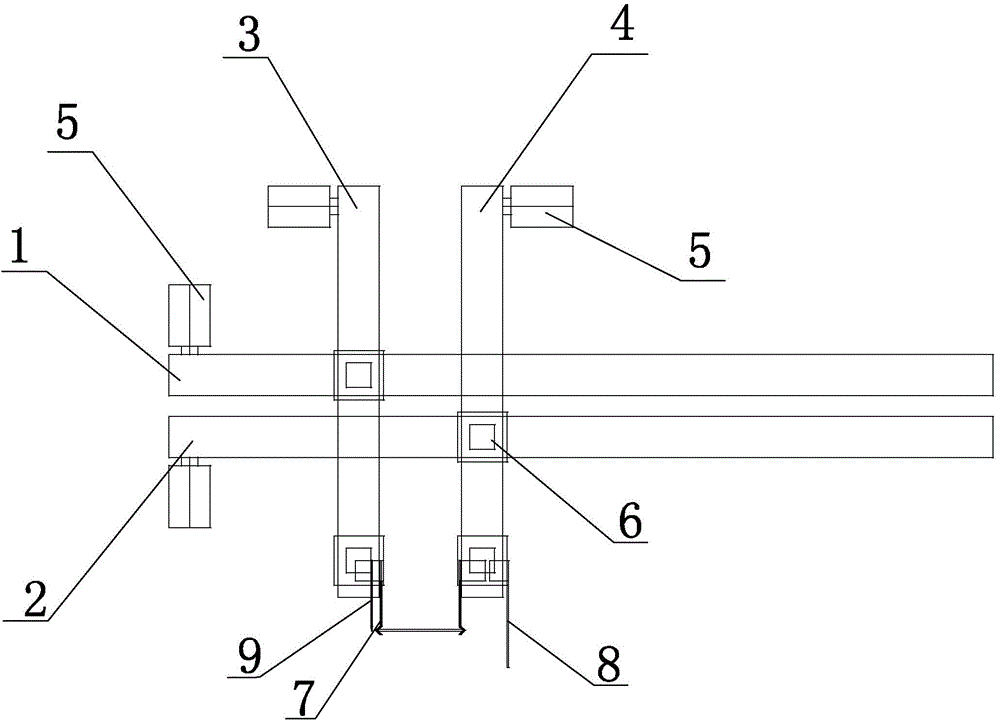

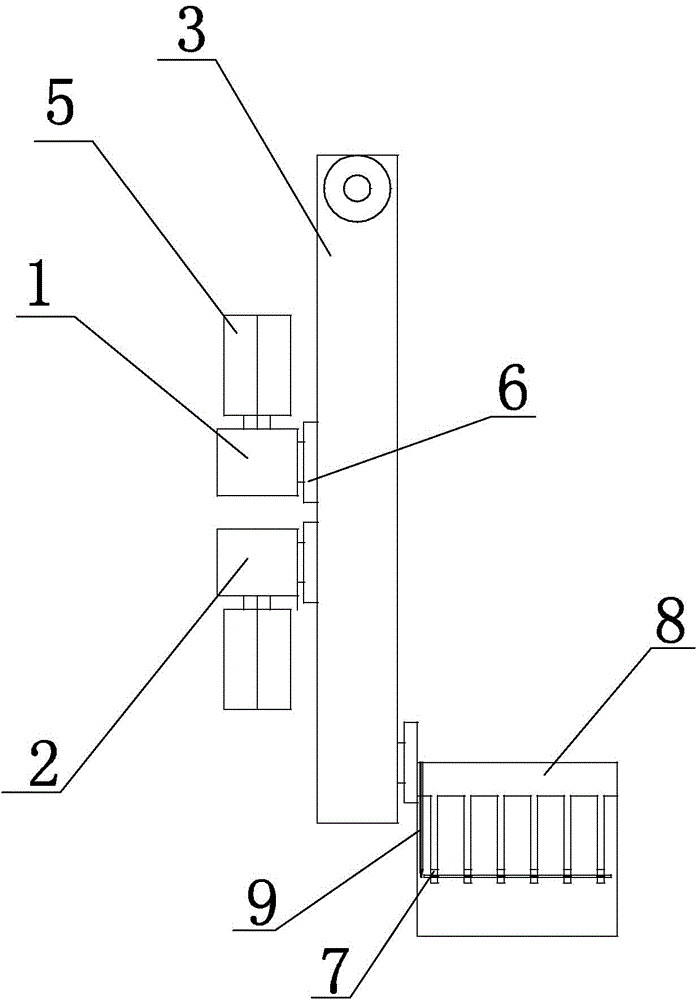

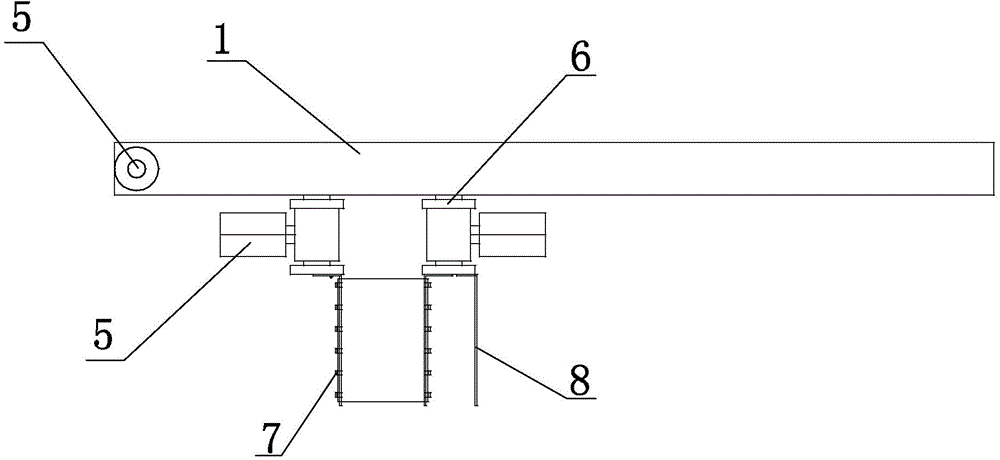

[0020] refer to Figure 1 to Figure 3 As shown, a fully automatic dip soldering machine includes a body, a transmission mechanism installed on the body and a control circuit for controlling the transmission mechanism. The transmission mechanism includes two parallel upper linear molds for controlling horizontal movement. Group 1 and lower linear module 2, two parallel left linear module 3 and right linear module 4 and stepper motor 5 for controlling vertical movement, the upper linear module 1 and lower linear module 2 Each is provided with a sliding table 6 for fixedly connecting the left linear module 3 and the right linear module 4, while the left linear module 3 and the right linear module 4 are each provided with a sliding table 6 respectively connected to a circuit board clamp 7, so The above-mentioned control circuit is connected to the linear module corresponding to the drive control of each stepper motor 5 to work. According to the different ways of use, the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com