Novel bearing running in machine

A bearing, a new type of technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of bearing temperature cannot be detected, pressure cannot be accurately controlled, and mass production cannot be satisfied, so as to ensure the running-in effect and quality, The effect of simple structure and convenient card installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

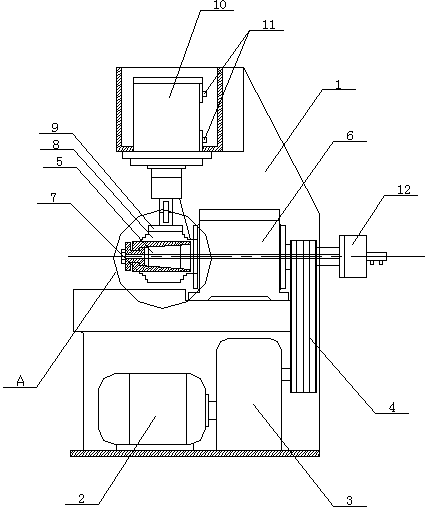

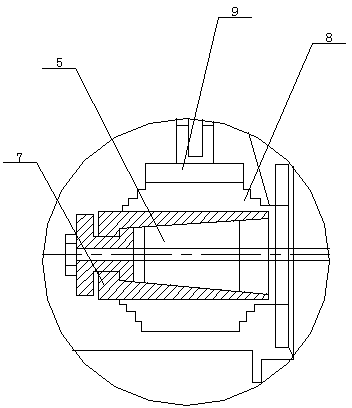

[0013] Referring to Fig. 1 and Fig. 2, this specific embodiment adopts the following technical scheme: it is composed of a body 1, a motor 2, a gearbox 3, a belt 4, a main shaft 5, a main shaft box 6, an expansion sleeve 7, a bearing 8, and a pressure head 9 , a pressure device 10, an oil inlet hole 11, and a clamping hydraulic cylinder 12; the lower end of the body 1 is provided with a motor 2, and the motor 2 is connected to the gearbox 3, and the gearbox 3 is connected to the main shaft 5 through the belt 4, and the main shaft 5 is installed on Inside the spindle box 6, the tail end of the spindle 5 is provided with a clamping pressure cylinder 12, the spindle 5 is provided with an expansion sleeve 7, the bearing 8 is installed on the expansion sleeve 7, the bearing 8 is provided with a pressure head 9, and the pressure head 9 It is connected with the pressure applying device 10, and the pressure applying device 10 is provided with an oil inlet hole 11.

[0014] The pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com