Workpiece surface machining system

A surface processing and workpiece technology, which is applied in the field of workpiece surface processing system, can solve the problems that the clamping angle of the workpiece cannot be guaranteed, reduce the production efficiency of the enterprise, waste labor intensity and other problems, achieve accurate movement, high grinding precision and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

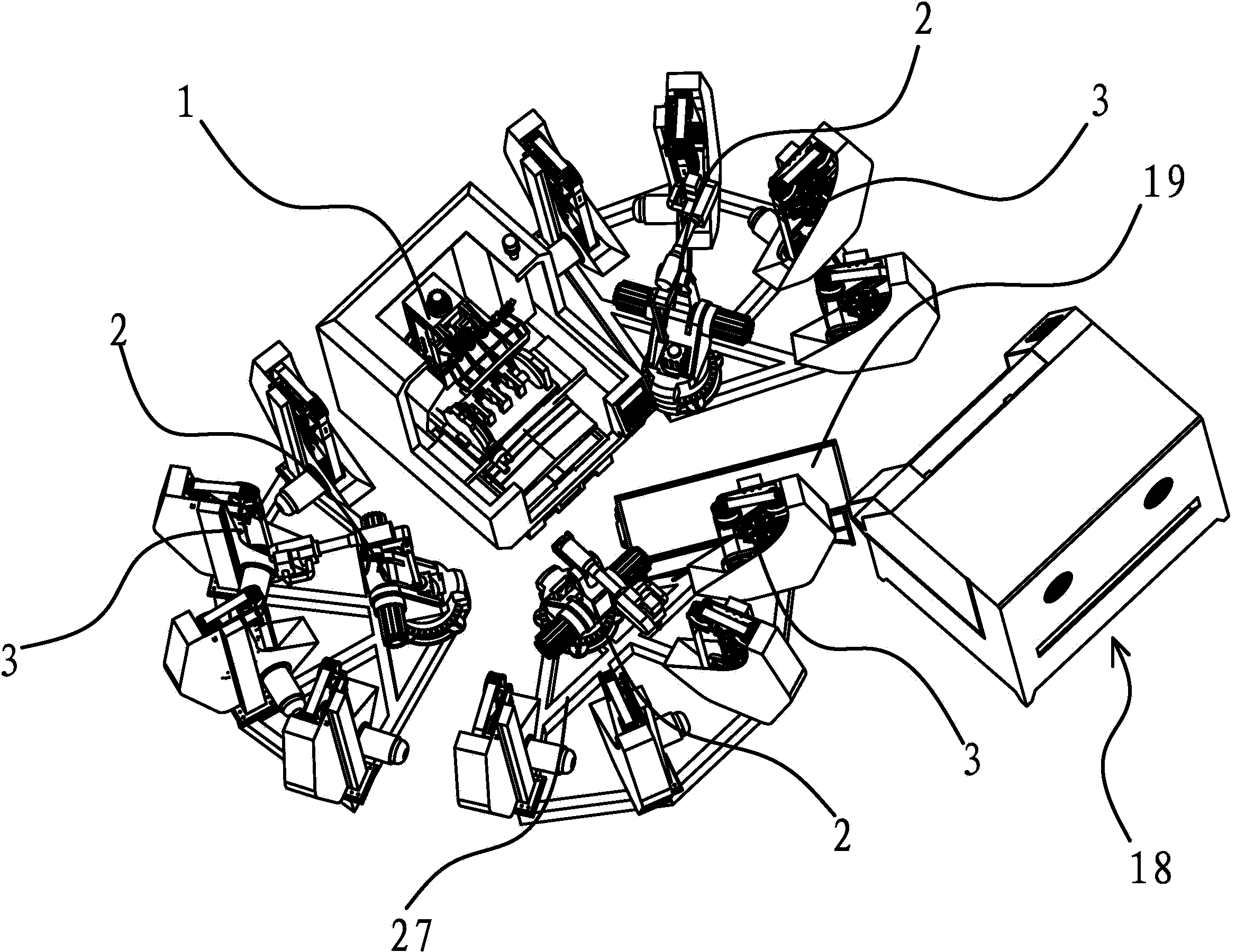

[0047] Such as figure 1 As shown, a workpiece surface processing system is arranged on the side of the machining center 1 for machining the workpiece. conveyor belt 19. The number of grinding units is 3 and is evenly distributed around the machining center 1 , and each grinding unit has a manipulator 2 and 4 grinding machines 3 . Each grinding unit is equipped with a mounting bracket, the manipulator 2 and each grinding machine 3 are installed on the mounting bracket 27, the mounting bracket 27 is fan-shaped, the manipulator 2 is fixed at the center of the mounting bracket 27, and each grinding machine 3 is evenly distributed on the On the arc edge of the mounting bracket 27.

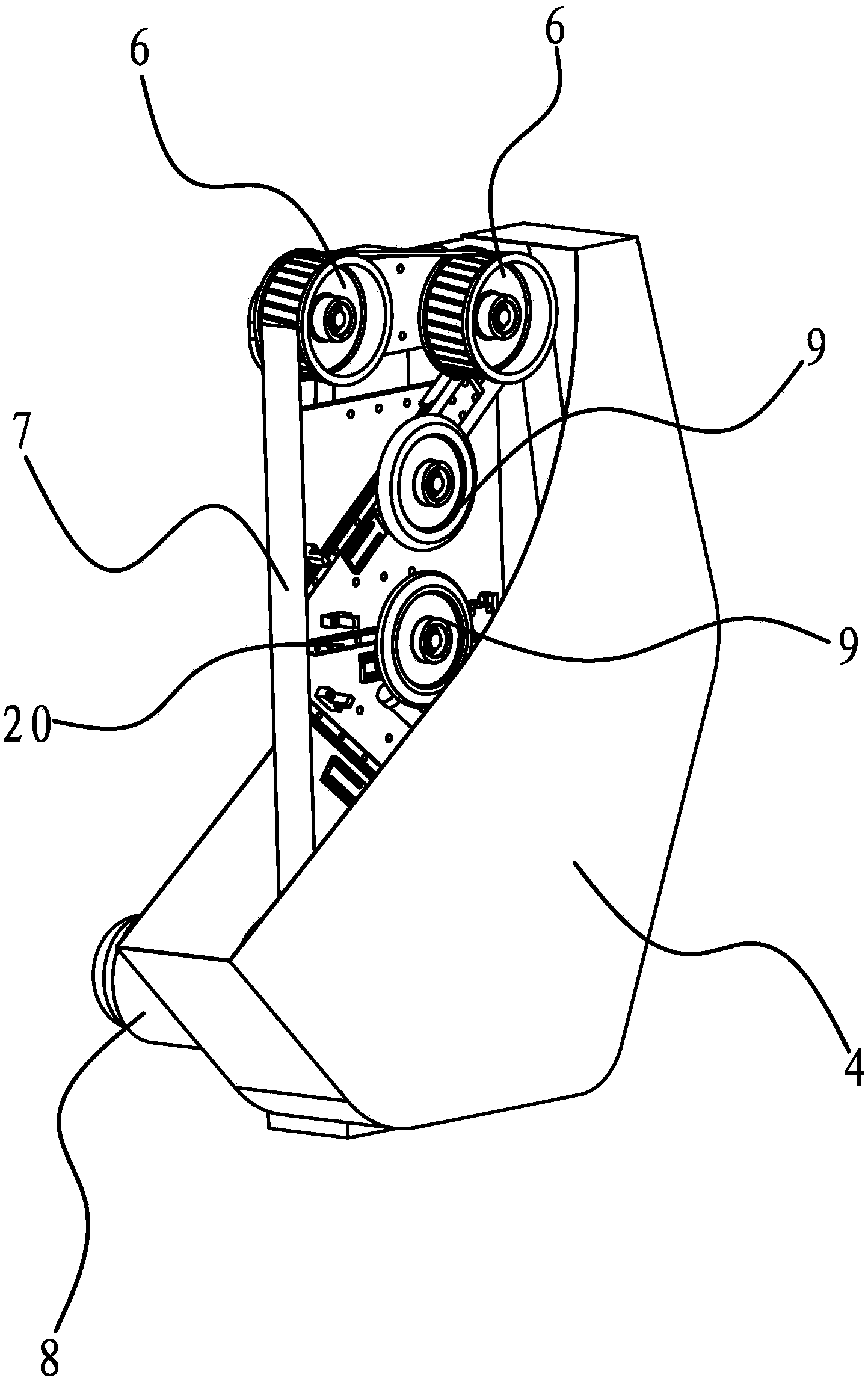

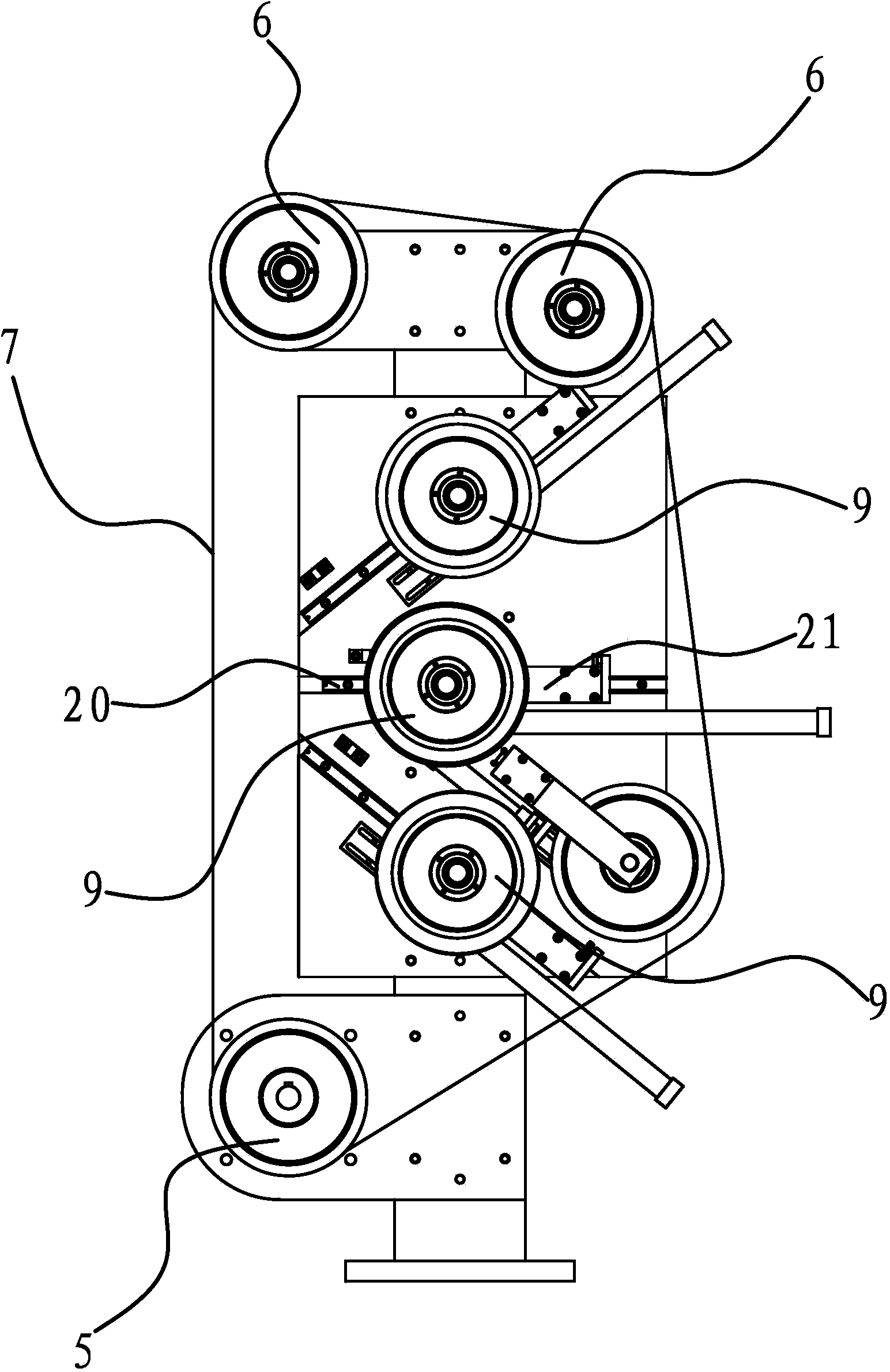

[0048] Such as Figure 5 , Figure 7 and Figure 8 As shown, the manipulator 2 can hold the machined workpiece at the machining center 1 and transport it to the corresponding grinding machine 3 for grinding according to the set sequence. Manipulator 2 comprises base 10, clamping frame 11 and clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com