Electronic device printing device

A technology of electronic printing and printing devices, applied in the direction of electric solid-state devices, printing, printing machines, etc., can solve the problems of high pollution treatment costs, large material consumption, complicated manufacturing procedures, etc., and achieve low material loss and low environmental requirements , the effect of reducing complexity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

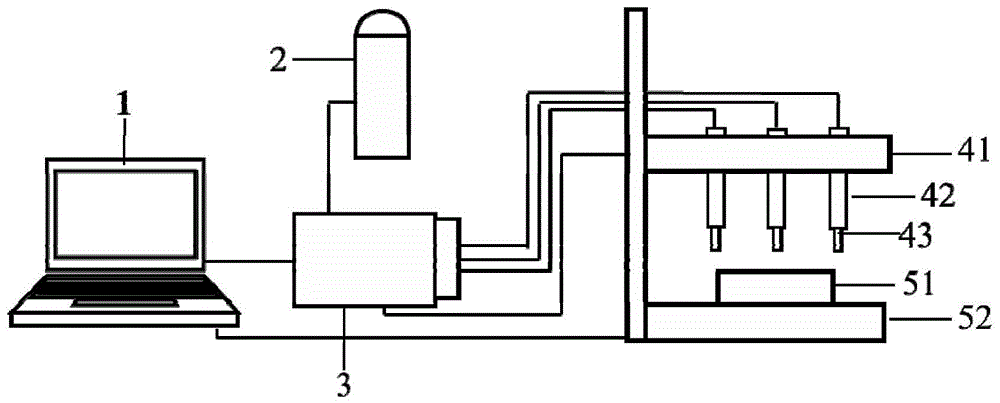

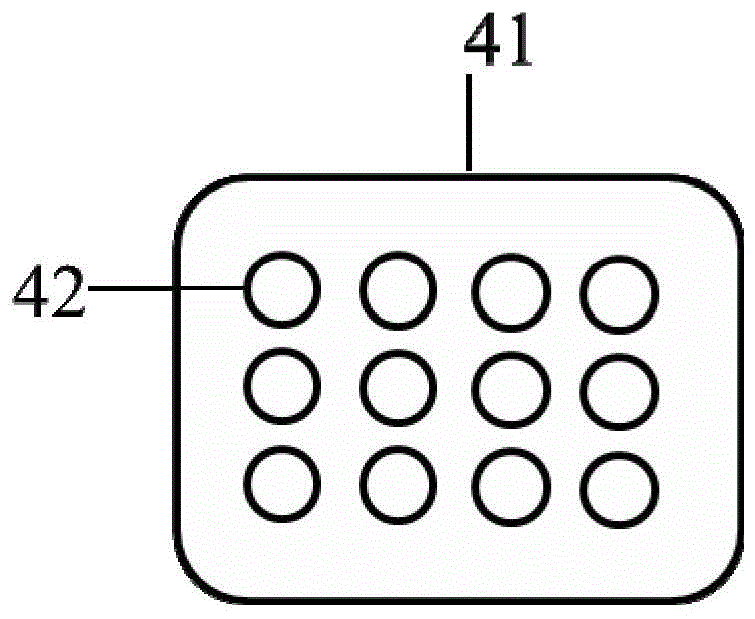

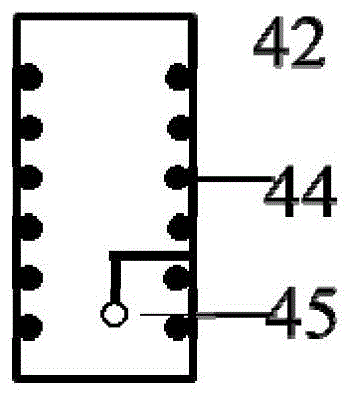

[0037] The present invention provides an electronic device printing device. The printing device includes a controller, an ink cartridge array mechanism and a substrate carrying mechanism, wherein:

[0038] The controller is used to control the ink cartridge array mechanism and the substrate carrying mechanism;

[0039] The ink cartridge array mechanism is used to provide electronic printing ink, and use the electronic printing ink to perform electronic printing;

[0040] The substrate carrying mechanism is used to carry electronic device substrates.

[0041] The above-mentioned electronic device substrate can be fixed on the substrate carrying mechanism by means of adhesive, lock or negative pressure; the substrate can be plastic, rubber, silicon, glass, silk fabric, polydimethylsiloxane (PDMS) , At least one of ceramics and paper.

[0042] Optionally, the device further includes a computer connected to the controller, the computer is used to generate printing control instructions; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com