Device for preparing carbon-doped chemical vapor deposition tungsten coating

A technology of chemical vapor deposition and gas mixing device, which is applied in the direction of coating, gaseous chemical plating, metal material coating process, etc., can solve the problems of increased maintenance cost, incomplete application, loss of raw materials, etc., to reduce energy consumption and The effect of reducing cost, reducing ineffective loss, and reducing recycling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

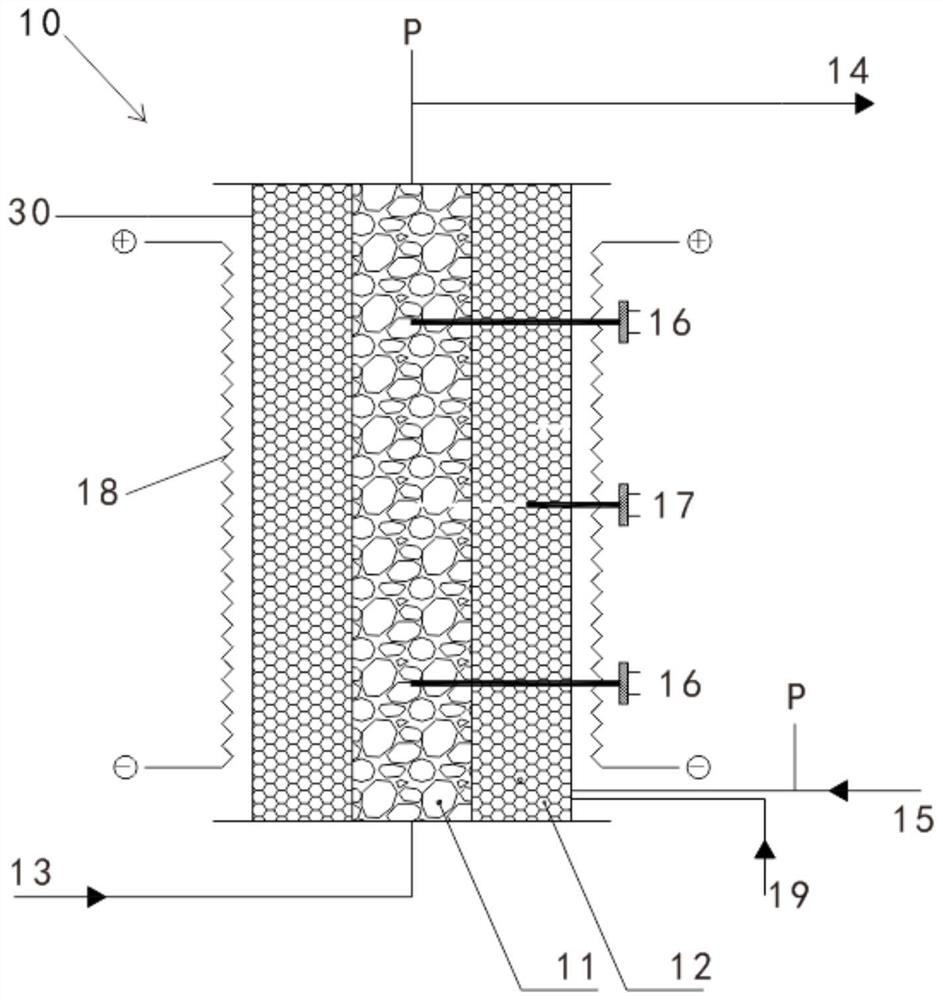

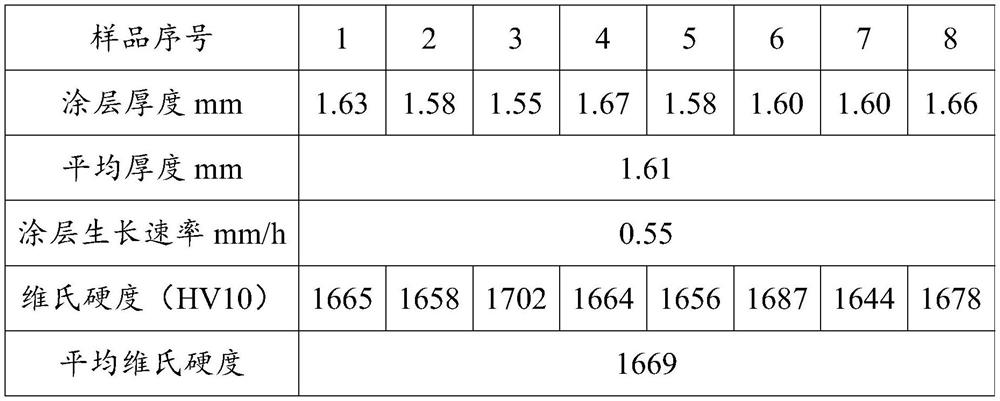

[0071] According to the carbon-doped chemical vapor deposition tungsten coating device provided by the present invention, the carbon-doped chemical vapor deposition tungsten coating is carried out, the substrate material is copper, the size is 40mm×40mm×5mm, and the target carbon-doped chemical vapor deposition tungsten coating is The thickness is 1.4-1.8mm, the Vickers hardness (HV10) is 1500-2000, and the quantity is 8 pieces.

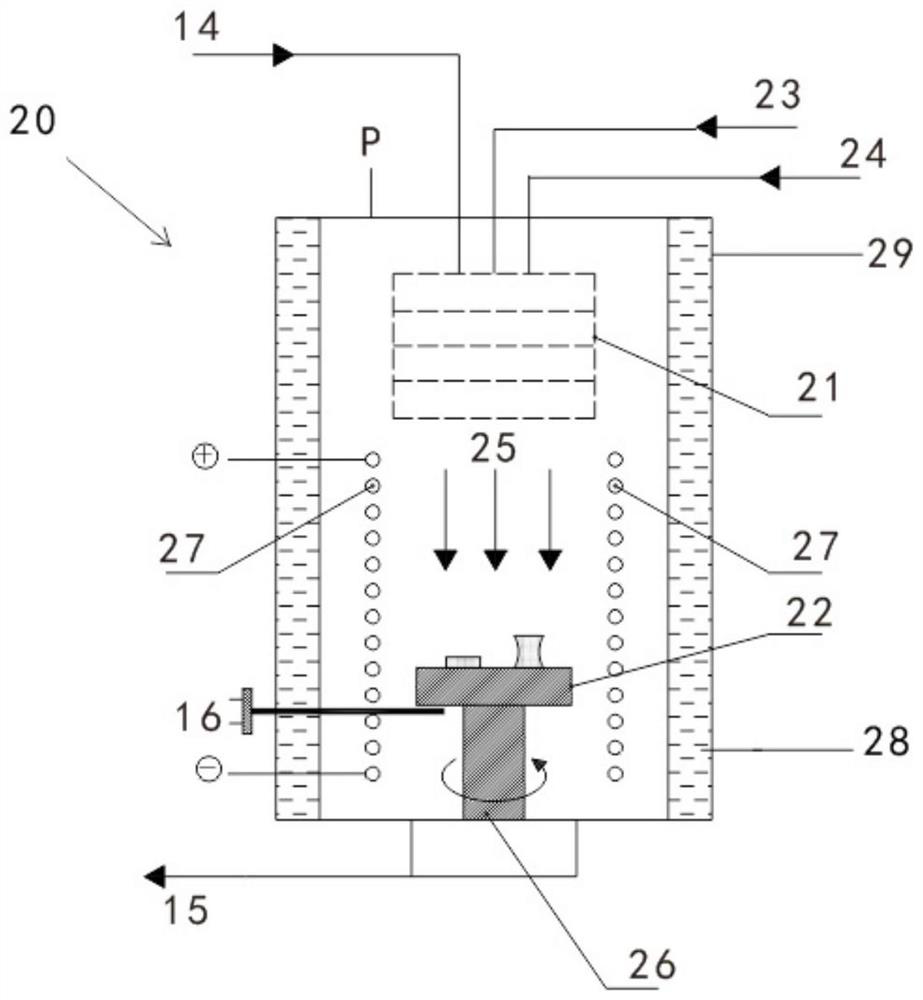

[0072] Among them, n-butane (C 4 h 10 ) gas enters the activation zone 11 through the first inlet pipe 13 and enters the gas mixing device 21 through the activation pipeline 14 after being activated at first, and tungsten hexafluoride (WF 6 ) gas and hydrogen (H 2 ) into the gas mixing device 21 through the second inlet pipe 23 and the third inlet pipe 24 respectively, and the copper base material to be coated is evenly placed on the deposition platform 22, the material of the deposition platform 22 is alumina, and the loading capacity is 8 pieces ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com