Container loading machine

A loader and container technology, applied in the direction of hoisting devices, lifting frames, and equipment for transporting goods, etc., can solve the problems of small adjustment range, inability to meet off-road or climbing requirements, large external dimensions and curb weight, etc., to achieve Adjustable platform width, reduced impact feeling, and high transport efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the present invention is further described:

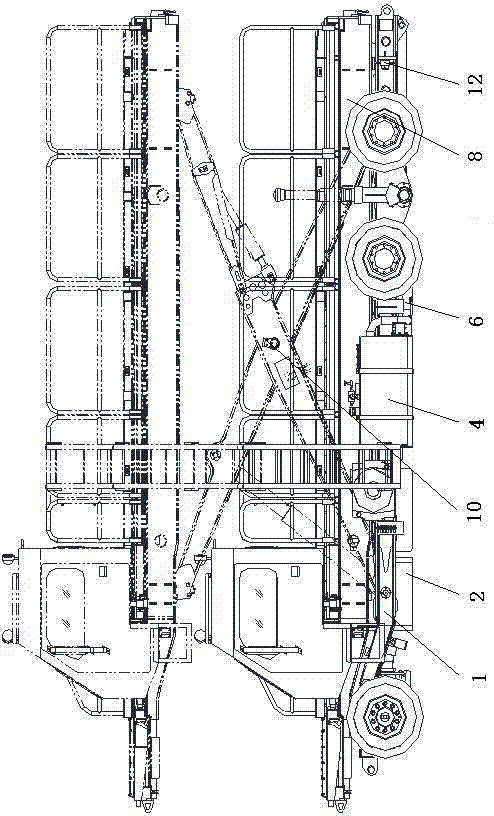

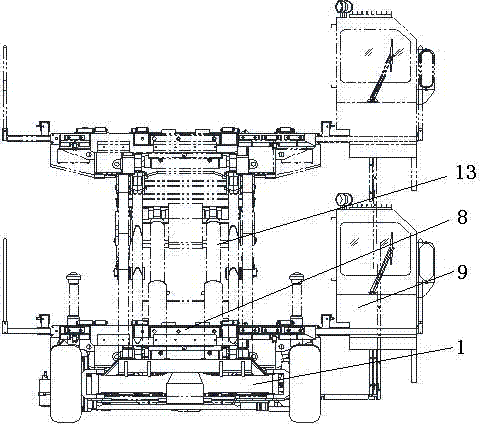

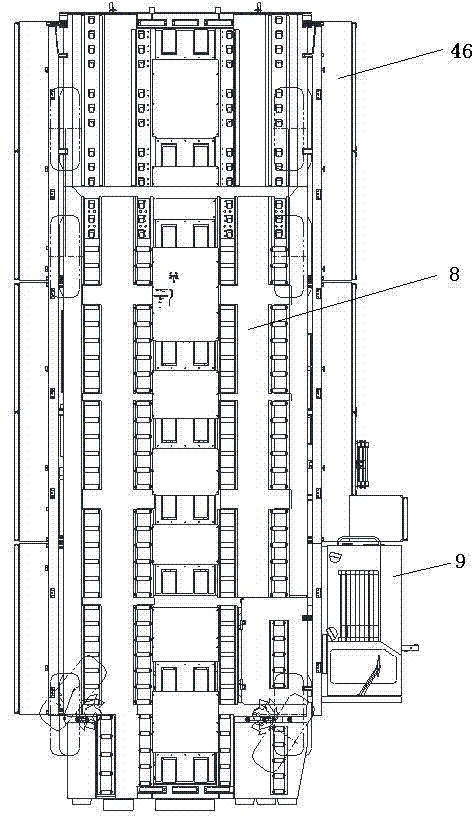

[0036] as attached figure 1 As shown, a container loader includes a car chassis 1, a transmission platform 8, a cab 9, a control system and a scissor support device, and the control system includes an operating system, a power system 2, a hydraulic system 4 and an electric control system 6, The operating system is located in the cab, and the chassis 1 is provided with a power system 2, a hydraulic system 4, and an electric control system 6. The upper end of the chassis 1 is connected to the transmission platform 8 through a scissor support device, and the transmission platform 8 is provided with a cab 9. The structures of the automobile chassis 1, the transmission platform 8, the driver's cab 9, the power system 2, the hydraulic system 4, and the electric control system 6 are the same as those of the prior art. Scissors frame 3, interior scissors frame 5, hinge shaft 7, fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com