High-efficient and environment-friendly transferring and unloading method for powder and powder container used for same

A powder and container technology, applied in the field of transshipment and unloading methods and the equipment used, can solve the problems of wasting resources and fuel, increasing tank pressure, and high unloading costs, achieving high efficiency, reducing transportation energy consumption, and transshipment low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The high-efficiency and environmentally-friendly transfer and unloading method for powder of the present invention is:

[0025] a. Set up a flexible, waterproof and foldable powder container on the transportation tool, and load the powder into the powder container and transport it to the destination;

[0026] b. The powder is sucked out from the powder container under negative pressure (the powder is sucked out from the powder container through a suction mechanism with a negative pressure fan) and transported to the destination powder yard or destination storage.

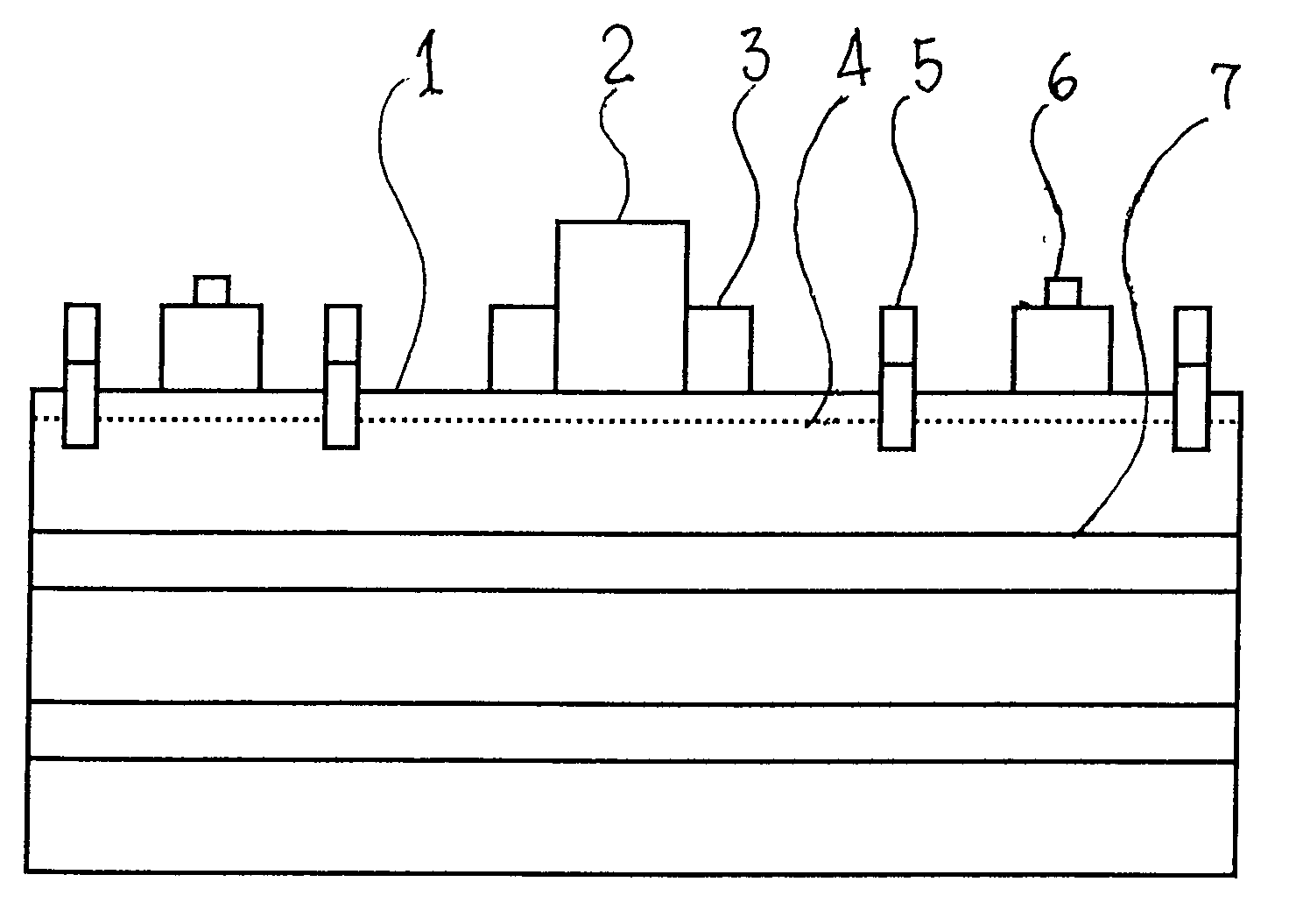

[0027] As shown in the figure, the powder container of the present invention is made of foldable flexible waterproof material (made of high-strength three-proof fabric tested and certified by the national railway quality inspection department, which can be waterproof, acid and alkali resistant, and high temperature resistant). A foldable flexible waterproof material wall 1 is provided with a powder channel 2 and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com