Valve

A valve seat and piston technology, applied in the field of valves, achieves simple manufacturing, large tolerance, weight and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

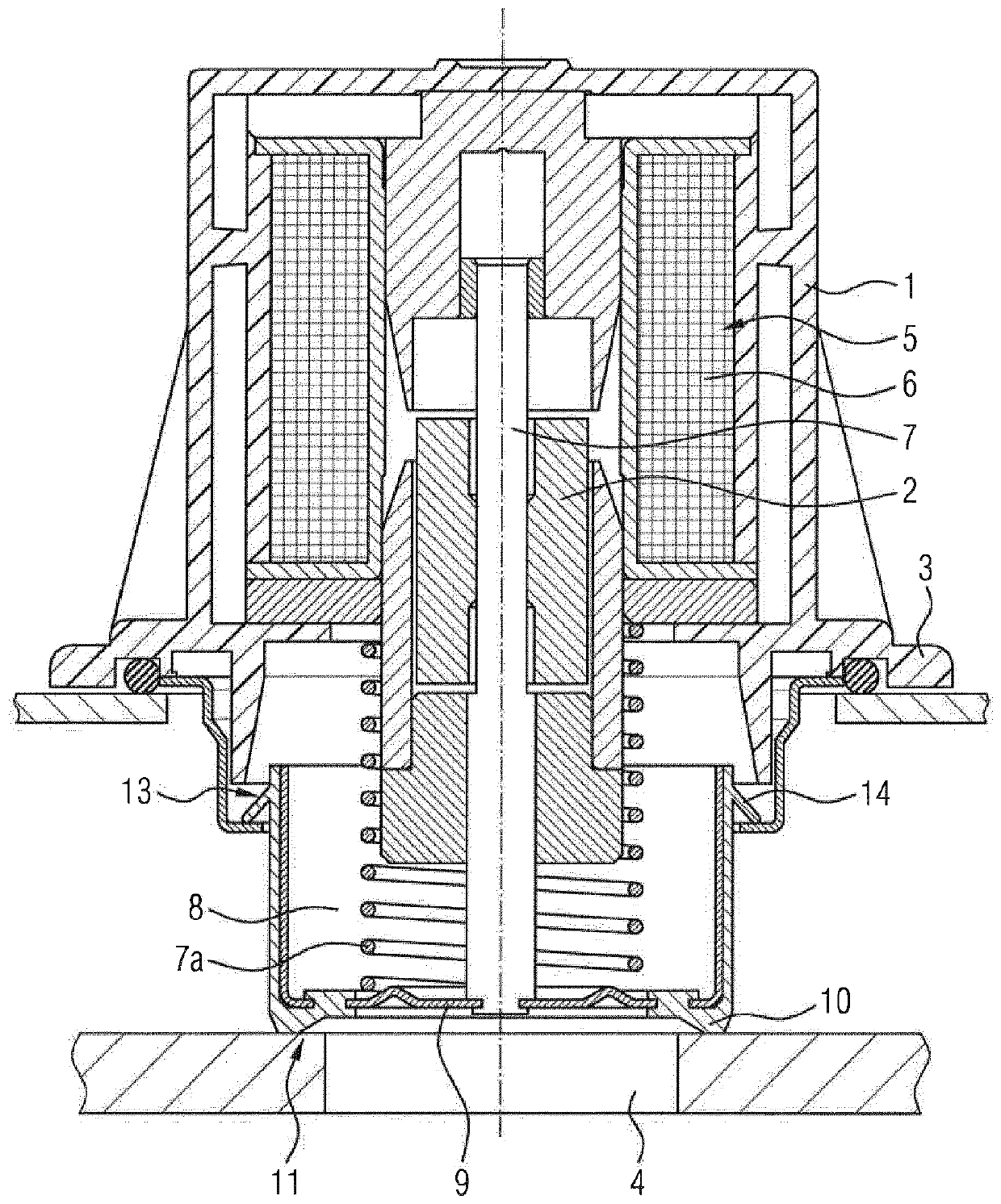

[0025] figure 1 The valve is shown, including the housing 1 . Furthermore, the housing 1 has an integral flange 3 , via which the housing 1 is flanged to a turbocharger (not shown) in the region of the bypass line 4 . A solenoid 5 with a coil 6 and a metal rod 7 is arranged in the housing 1 . The metal rod 7 is connected to a pot-shaped piston 8 which has a seal 10 on the circumference of its base 9 . In the closed position shown, the sealing structure 10 bears against the valve seat 11 in order to close the bypass line 4 so that no medium can flow from the line 4 into the line 12 . In this case, the spring 7 a pushes the piston 8 against the valve seat 11 . A further seal 13 with a sealing lip 14 is arranged at the open end of the piston 8 . If the solenoid 5 is energized, a magnetic force acts on the armature 2 , thereby moving the piston 8 in the direction of the housing 1 . The sealing lip 14 here seals the piston 8 relative to the housing 1 .

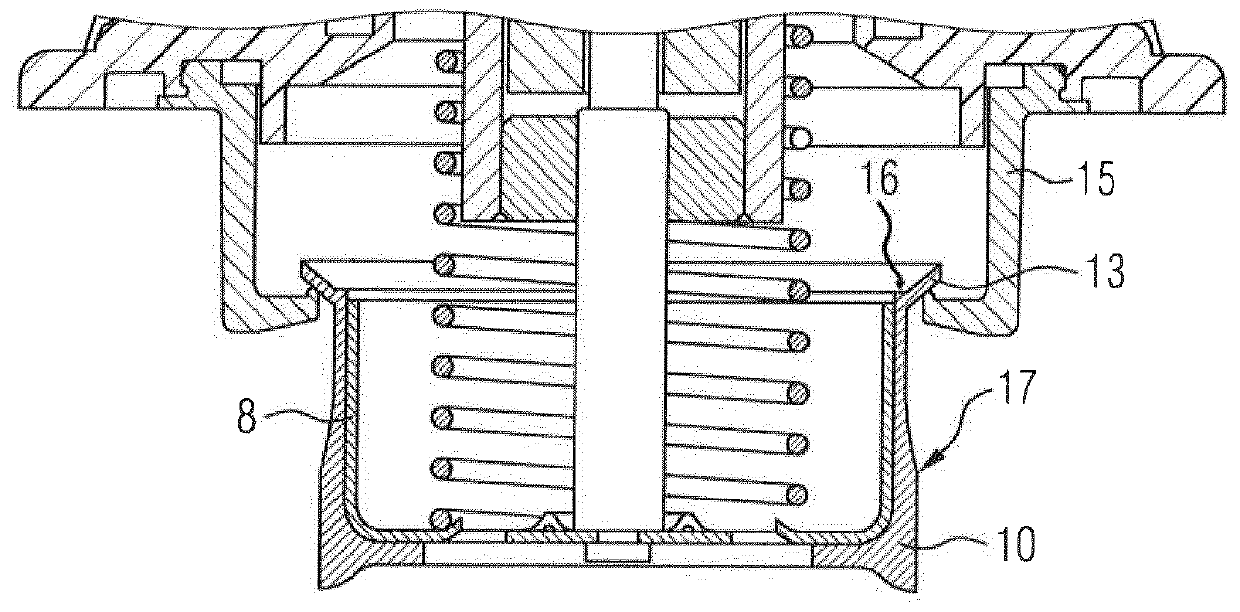

[0026] figure 2 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com