Flap unloading type air lock controllable unloading machine

A technology of unloading machine and unloading mechanism, which is applied in the direction of conveyor objects, transportation and packaging, etc., and can solve the problems of accurately controlling the state of material distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

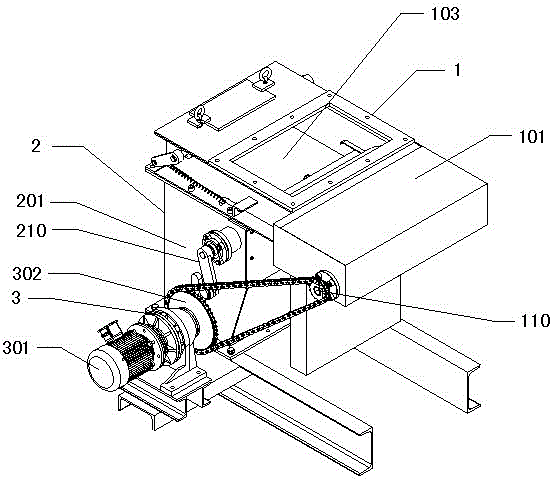

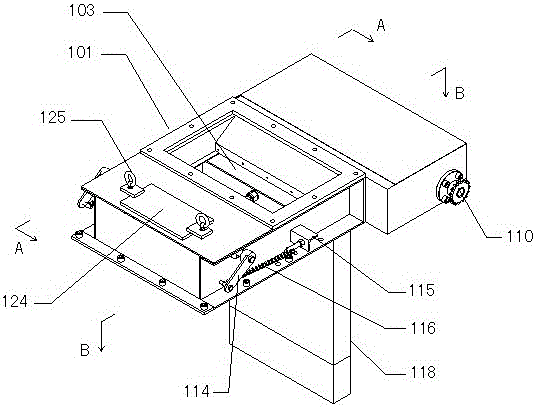

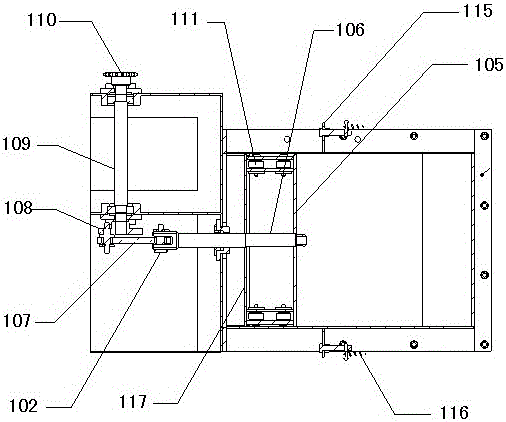

[0022] Such as Figure 1 to Figure 6 As shown, the panel-discharging air-lock controllable unloading machine of the present invention includes a material distribution mechanism 1, a material discharge mechanism 2 and a power mechanism 3; the material distribution mechanism includes a material distribution box 101 and a pushing device 102, and The top of one side of the material box body is provided with a material inlet 103, and the bottom of the other side of the material distribution box body is provided with a material discharge port 104. The pushing device includes a front push plate 105, a push rod 106, a connecting rod 107, an eccentric wheel 108, and a crank Shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com