Split-level superimposed biological filtration and oxygenation device

A biological filtration and split-layer technology, which is applied in the direction of sustainable biological treatment, aerobic process treatment, animal husbandry, etc., can solve the problems of large space occupation, low efficiency, and the failure of biological filters to continue to work normally for a long time, so as to ensure normal operation running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

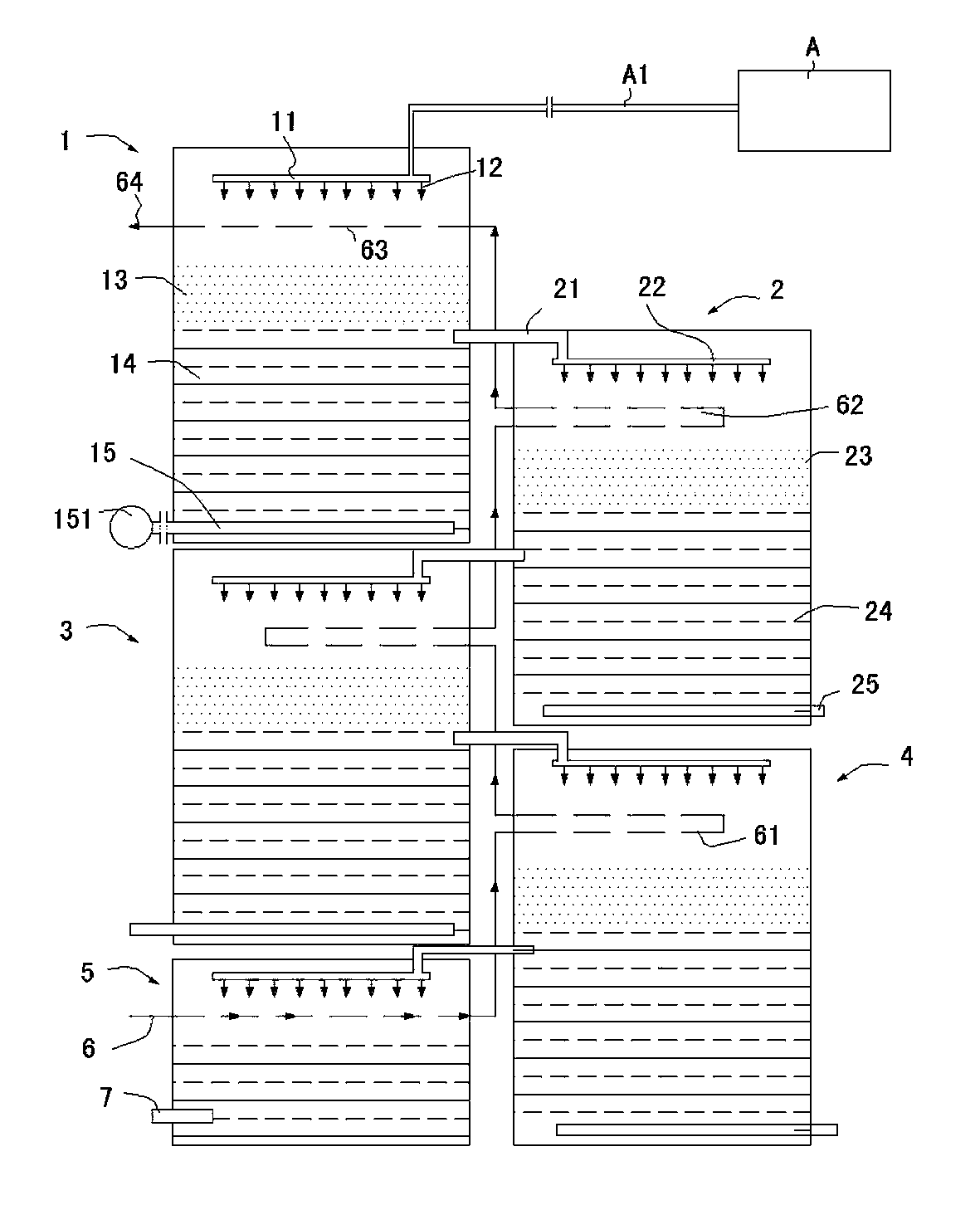

[0016] In this embodiment, four circulating water containers are taken as an example for illustration, and of course, the quantity in actual implementation can be selected according to the actual situation. The size of each circulating water container can be set as required. In this embodiment, it is 0.8*0.88*1.1m, and the manufacturing material can be stainless steel or fiberglass.

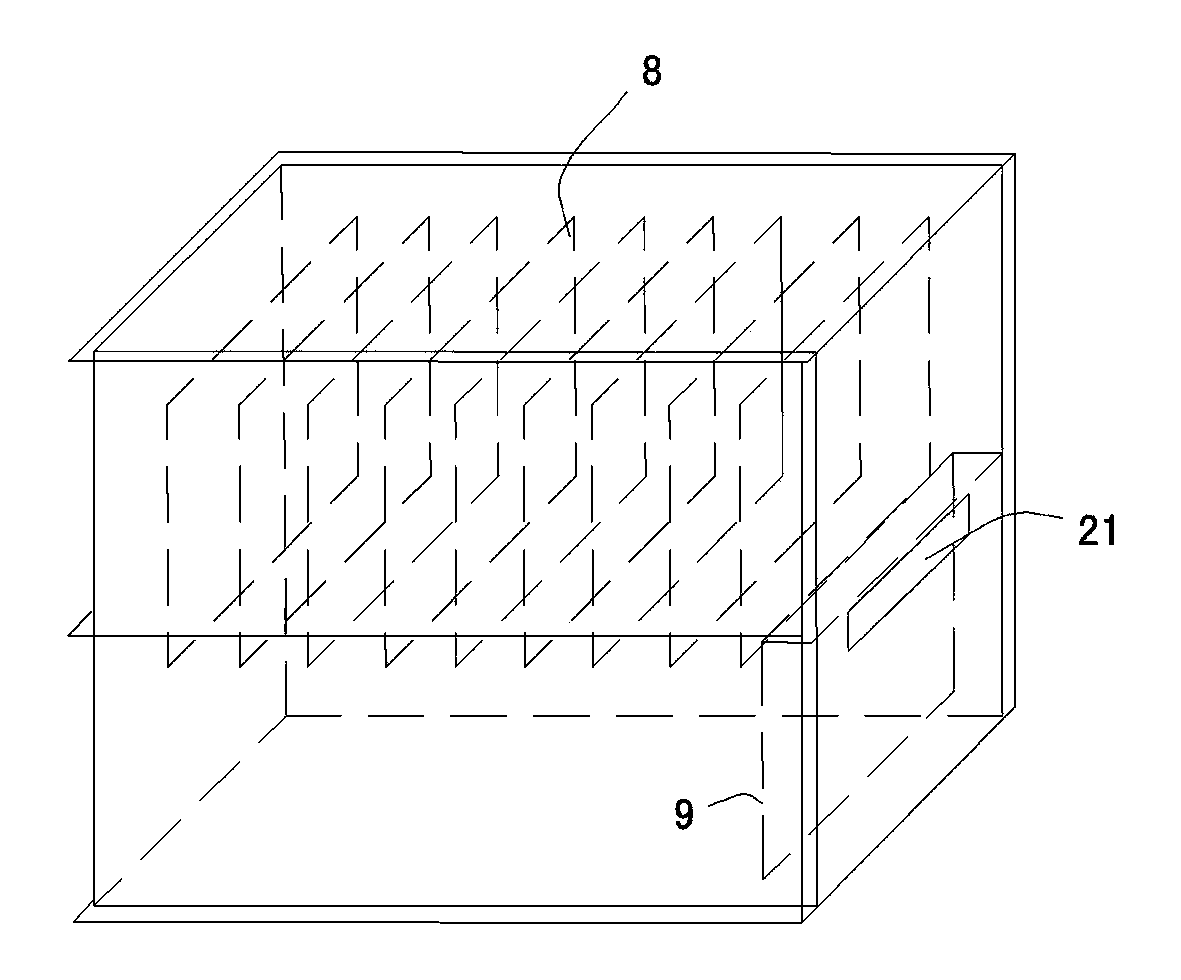

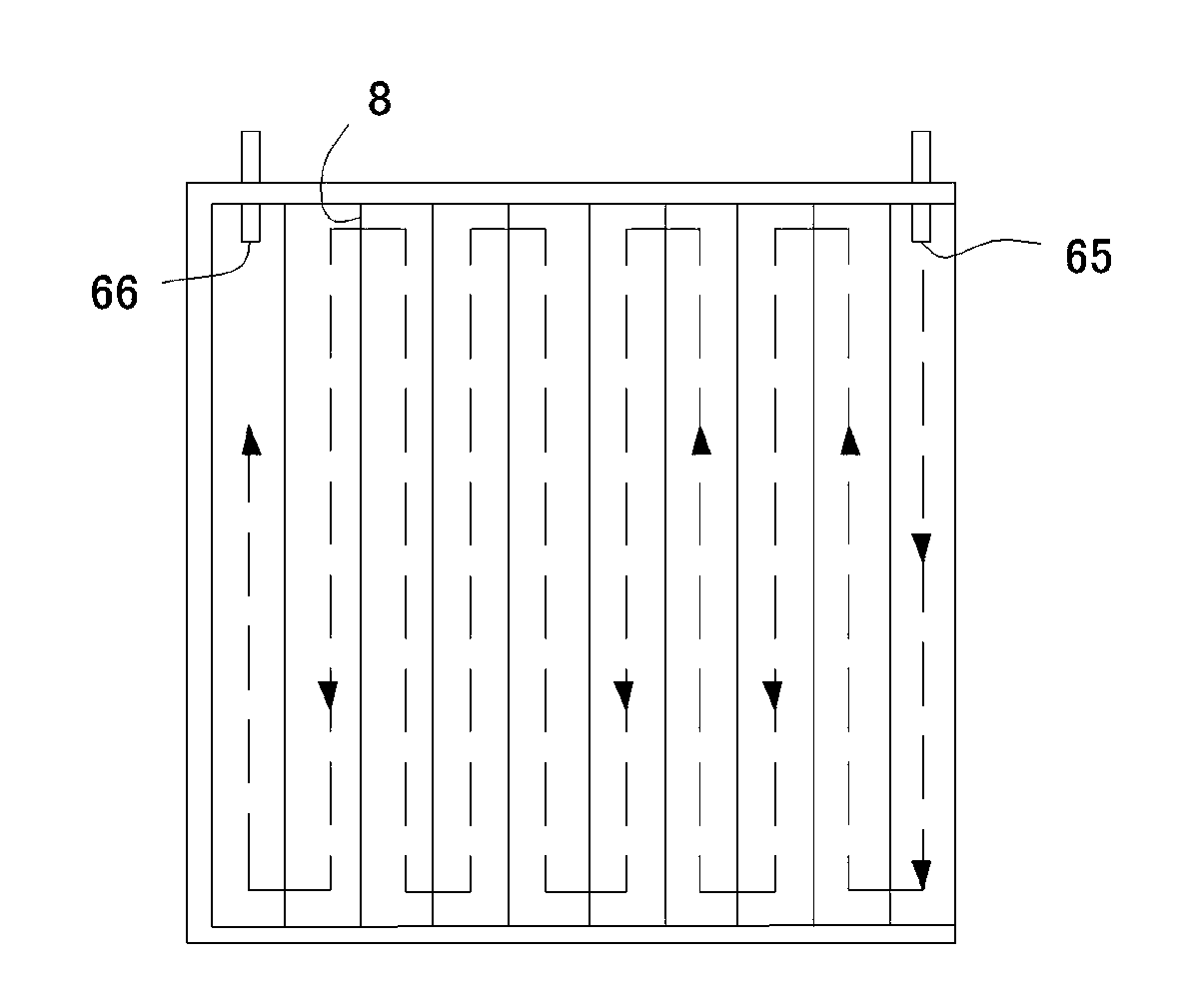

[0017] see figure 1 . From top to bottom, the device is composed of the first circulating water container 1, the second circulating water container 2, the third circulating water container 3, the fourth circulating water container 4 and the mixing container 5 stacked in staggered layers in series through connecting water pipes. The water in the breeding pond A is connected to the cavity of the porous water shower plate 11 in the inner cavity of the first circulating water container 1 located at the highest place through the delivery pipeline A1. Each circulating water container has the same str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com