Flexible bituminous mixture, preparation method and application thereof

A technology of asphalt mixture and mixture, applied in the field of rollable asphalt mixture, the preparation field of said rollable asphalt mixture, can solve the problems of little research and difficulty of asphalt pavement, achieve reliable quality assurance and reduce disadvantages Affecting and alleviating traffic congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

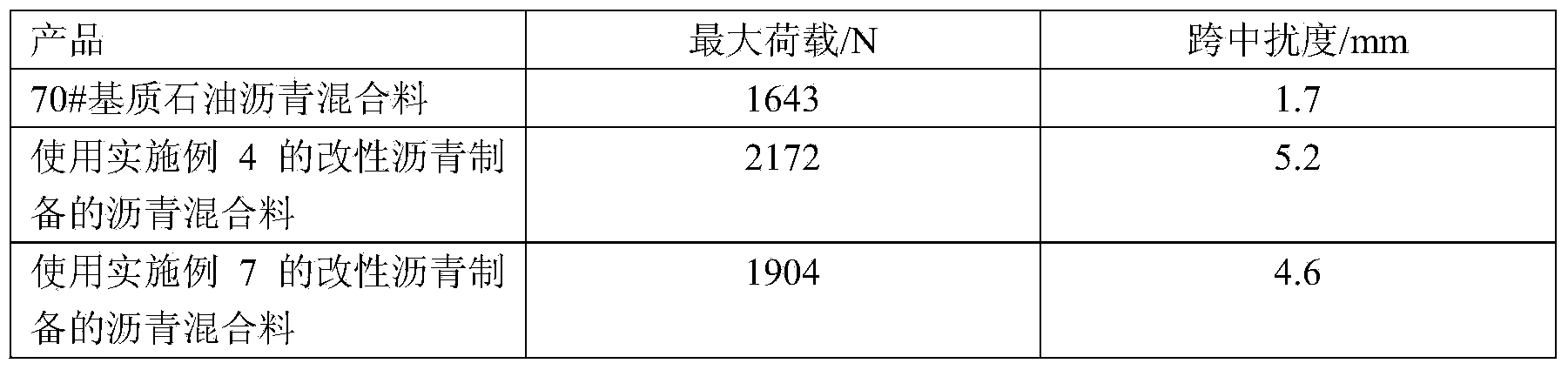

Examples

preparation example Construction

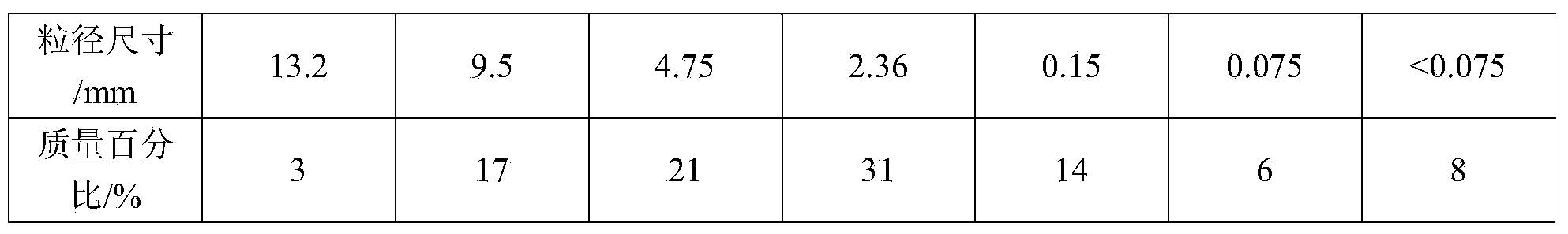

[0031] The present application also provides a method for preparing the rollable asphalt mixture according to the present application, the method comprising: mixing the additive with the aggregate; mixing the mixed mixture with petroleum asphalt; and mixing the previous The mixture obtained after the mixing step is mixed with filler to obtain a curly asphalt mixture.

[0032] In this field, mineral materials are divided into aggregates and fillers, which essentially refer to stone materials. Generally speaking, aggregates with a particle size greater than 0.075mm, and fillers with a particle size below 0.075mm. In the preparation method described in this application, the mineral material is divided into aggregate and filler and added separately.

[0033] Wherein, the mixing temperature of the additive and the aggregate is 160-210°C, and the mixing time is 20-120 seconds; the mixing temperature of the mixed mixture and petroleum asphalt is 160-210°C, and the mixing time The mi...

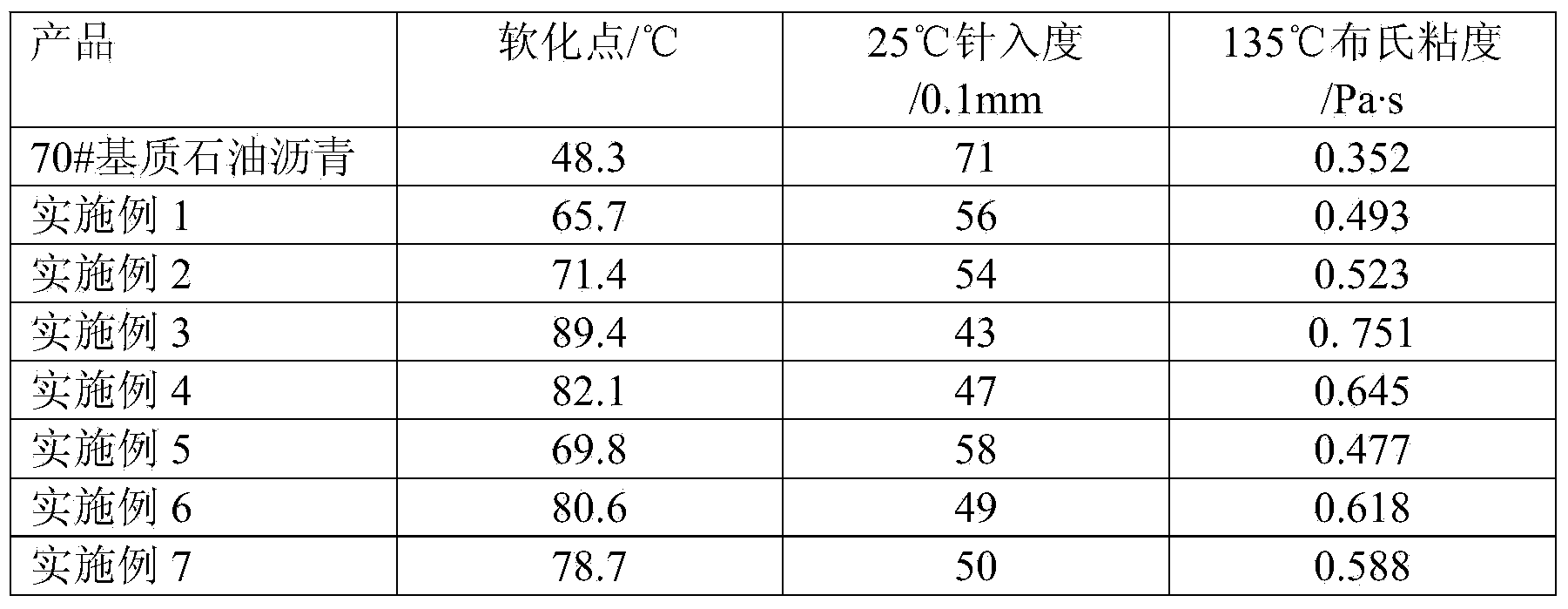

Embodiment 1

[0044] Heat the Zhonghai 70# base petroleum asphalt with a mass ratio of 78% (based on the quality of the prepared modified asphalt) to 160°C, add an additive with a mass ratio of 22% (based on the quality of the prepared modified asphalt), and stir to be added Soluble in petroleum asphalt, cut with a high-speed shearing machine at a speed of 4000r / min for 30 minutes, dissolve evenly, put it in an oven, and develop it at 160°C for 30 minutes to obtain modified asphalt.

Embodiment 2

[0046] Heat the Zhonghai 70# base petroleum asphalt with a mass ratio of 82% (based on the quality of the prepared modified asphalt) to 170°C, add an additive with a mass ratio of 18% (based on the quality of the prepared modified asphalt), and stir to be added Soluble in petroleum asphalt, cut with a high-speed shearing machine at a speed of 5000r / min for 30 minutes, dissolve evenly, put it in an oven, and develop it at 160°C for 30 minutes to obtain modified asphalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com