Method for preparing phase transition insulation mortar and test method thereof

A technology of thermal insulation mortar and testing method, which is applied in the direction of material thermal development, etc., can solve the problems such as the standard is not yet perfect, and achieve the effect of rapid and effective preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation method of phase change thermal insulation mortar:

[0028] The first step is to screen porous vitrified microbeads with a particle size within 2mm as the carrier material, and dry them in an oven at 50°C for 2 hours before preparation;

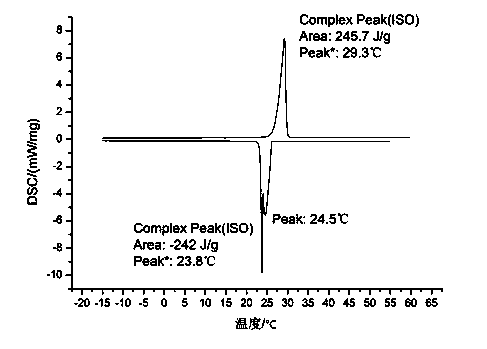

[0029] The second step is to carry out the capillary adsorption of vitrified microbeads on the phase change material n-octadecane under 50°C water bath heating and 5000rpm mechanical stirring to obtain a composite phase change material, and repeat this step to obtain sufficient composite phase change materials;

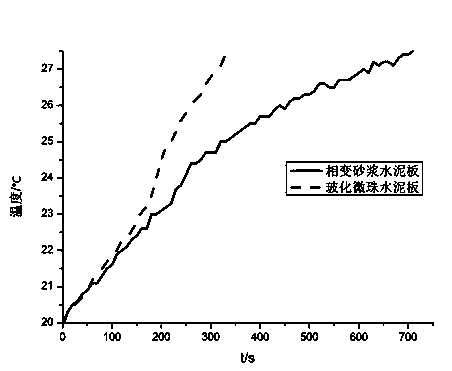

[0030] The third step is to mix the composite phase change material, cement and water in proportion to prepare the phase change insulation mortar, in which the mass ratio of cement to water is 2:1, and the ratio of cement to composite phase change material is 3:1, and then use specific specifications The mold is used to make a 20cm*20cm*1.3cm phase-change mortar cement board and a corresponding blank test sample (th...

Embodiment 2

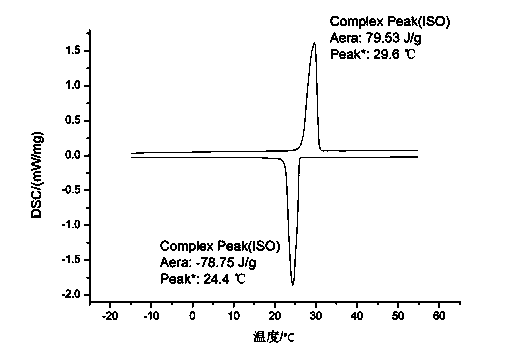

[0033] Preparation method of phase change thermal insulation mortar:

[0034] The first step is to screen porous vitrified microbeads with a particle size within 2mm as the carrier material, and dry them in an oven at 50°C for 3 hours before preparation;

[0035] The second step is to carry out the capillary adsorption of vitrified microbeads on the phase change material n-octadecane under 100°C water bath heating and 2000rpm mechanical stirring to obtain a composite phase change material. Repeat this step to obtain sufficient composite phase change materials;

[0036] The third step is to mix the composite phase change material, cement and water in proportion to prepare the phase change insulation mortar, in which the mass ratio of cement to water is 2:1, and the ratio of cement to composite phase change material is 4:1, and then use specific specifications The mold is used to make a 20cm*20cm*1.3cm phase-change mortar cement board and a corresponding blank test sample (that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com