Decoloration chamber of decoloration device

A technology of discharging device and heating device, applied in the field of fading room, can solve the problems of uneven fading of plastic, different PH value of plastic, different chemical composition, etc., and achieve the effect of large market promotion value and simple and practical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

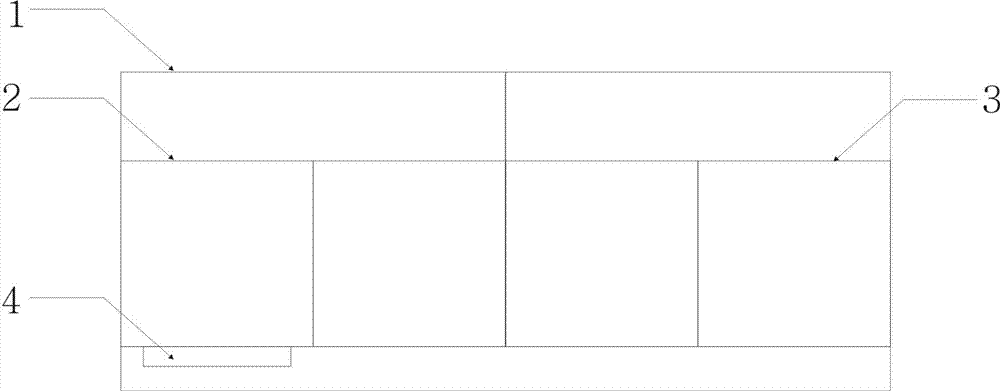

[0014] Such as figure 1 As shown, the present invention includes a decolorization chamber, and the decolorization chamber is divided into a first decolorization chamber and a second decolorization chamber, and two chambers are respectively arranged in the first decolorization chamber and the second decolorization chamber, and the decolorization chamber and the discharge chamber The device is connected, one chamber in the first fading chamber is provided with sodium carbonate solution, the other chamber is provided with clear water, one chamber in the second fading chamber is provided with hydrogen peroxide solution, and the other chamber is provided with clear water, the A heating device is provided at the bottom of the first fading chamber.

[0015] The invention solves the problem in the prior art that the pH value of the plastic is different due to the different chemical composition when the plastic is colored, so the plastic will fade unevenly, and the structure of the inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com