Semi-conductive internal shielding material composition, semi-conductive internal shielding material and manufacturing method thereof, as well as medium and low-pressure and 110KV cable

A low-voltage cable, inner shielding technology, applied in the direction of power cables with shielding layer/conductive layer, etc., can solve the problem of not being able to use 110kV rated cables, and achieve the effect of high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

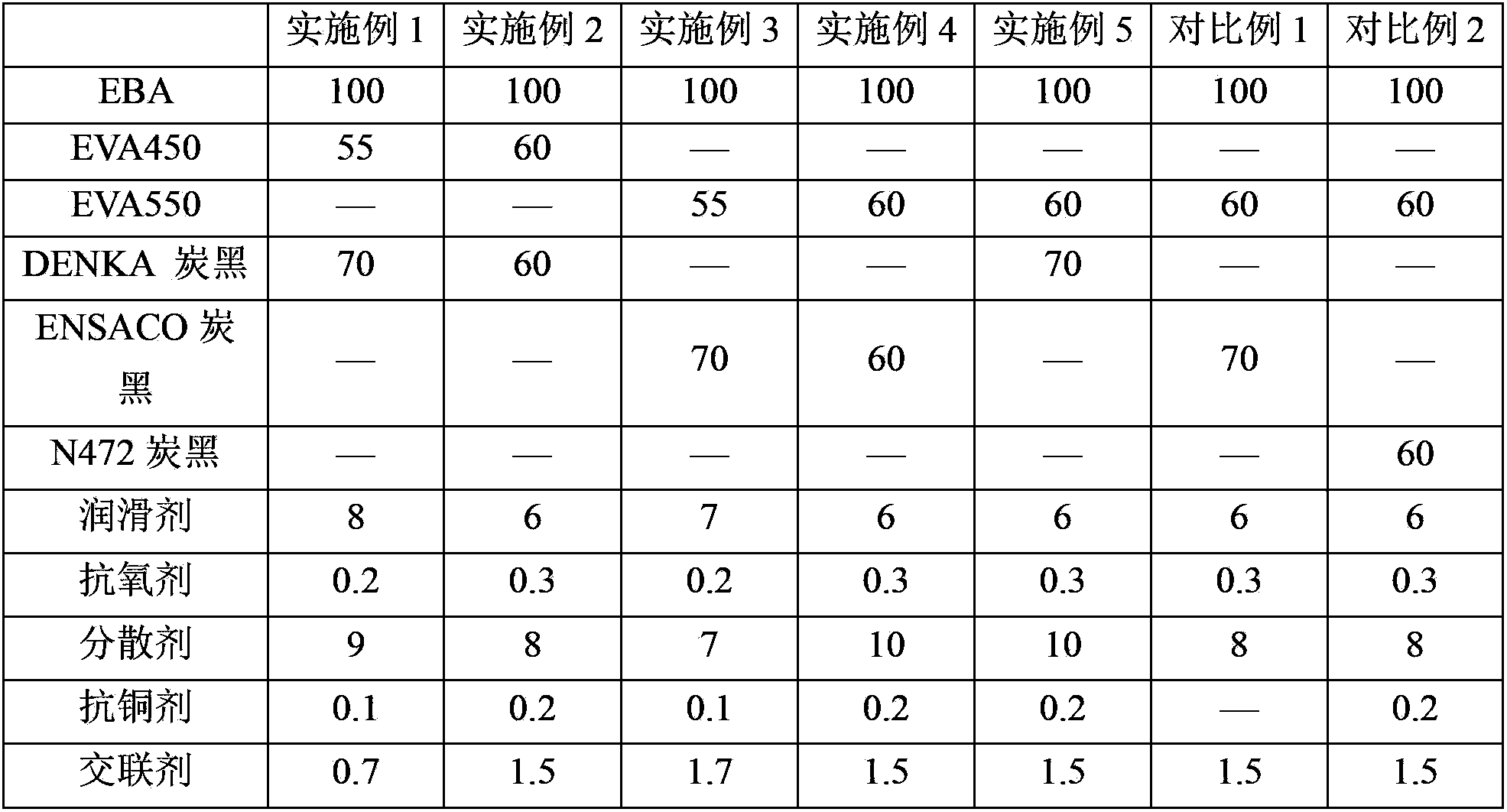

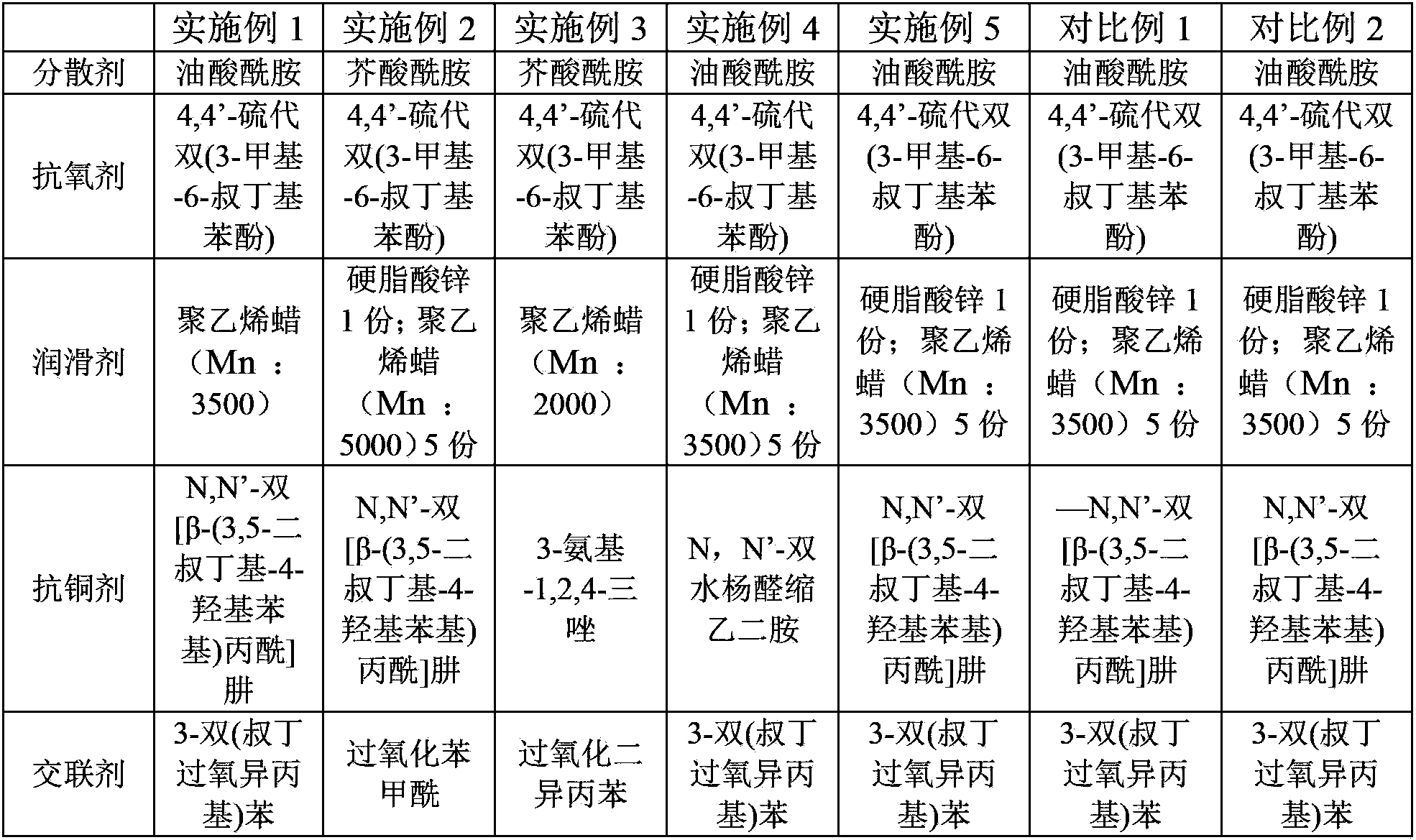

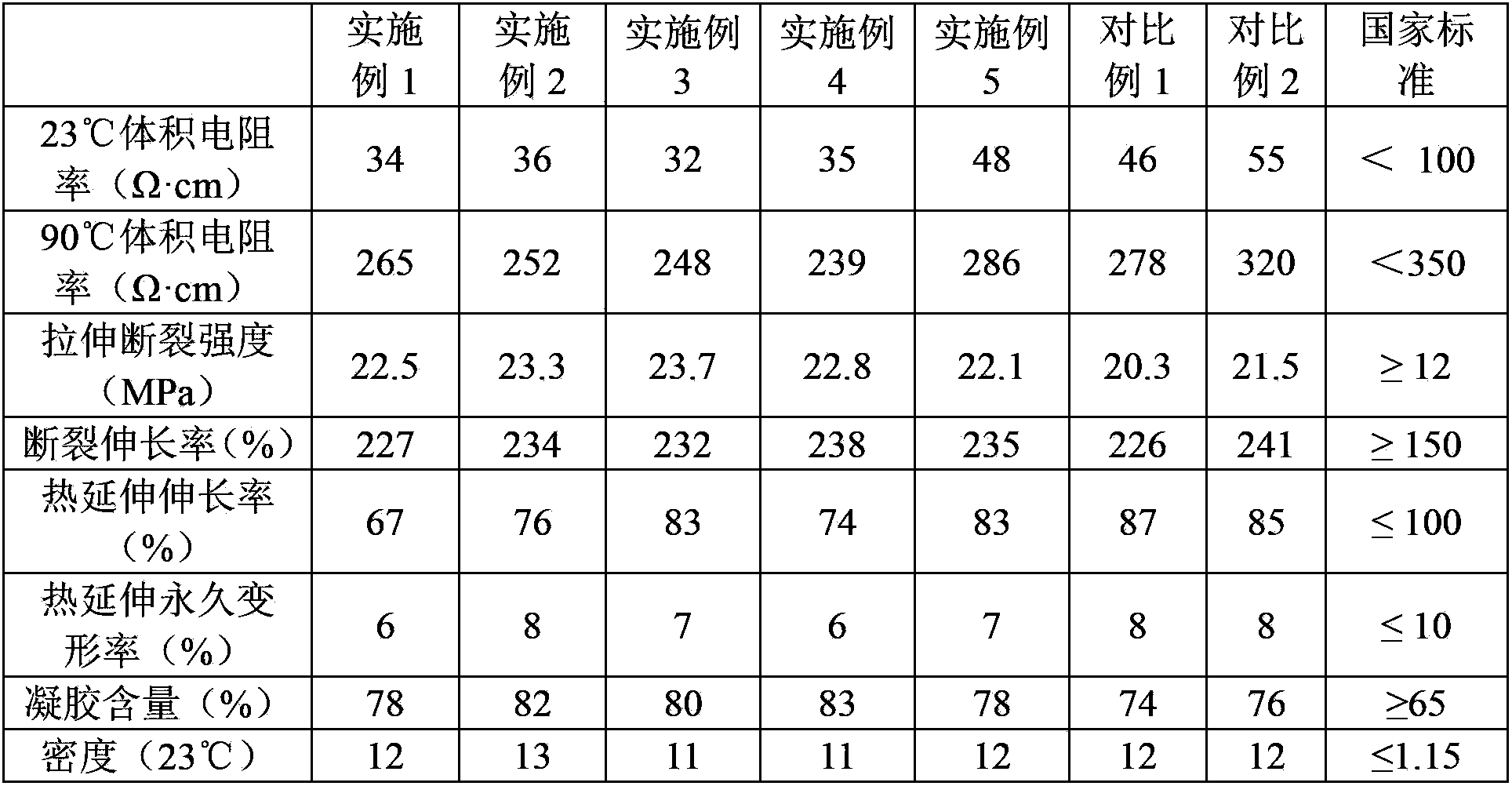

Examples

preparation example Construction

[0043] According to the preparation method of the semi-conductive inner shielding material for 110 kV cables of the present invention, the present invention utilizes the self-weight , the conditions for mixing and contacting with the crosslinking agent in a high-speed mixer are not particularly limited. Preferably, the conditions for mixing and contacting in step (2) include: contact temperature is 60-80°C, preferably 65-70°C; contact time Specifically, the mixed contact can be first mixed with the semi-conductive inner shielding cable material premix granules for 110 kV cables and the cross-linking agent for 5-8 minutes, and then left to stand after mixing to allow the cross-linking agent to soak into the 110 kV cables. Semi-conductive inner shielding material 2-3h, preferably 2.5-3h.

[0044] According to the method for preparing a semi-conductive inner shielding material for 110 kV cables of the present invention, preferably, the method further includes vacuum packaging the...

Embodiment 5

[0053] The extrusion process parameters of Example 5 are the same as those of Example 1 above, but all operations are carried out in ordinary workshops without providing dust-free and positive pressure preparation conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com