Composition for an FPCB coverlay and method for producing the same

A circuit substrate, flexible printing technology, applied in the direction of printed circuit manufacturing, printed circuit, printed circuit, etc., can solve the problems of thickness deviation, lower productivity, lower overall characteristics, etc., achieve excellent flexibility and electrical characteristics, increase design freedom, The effect of shortening the production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

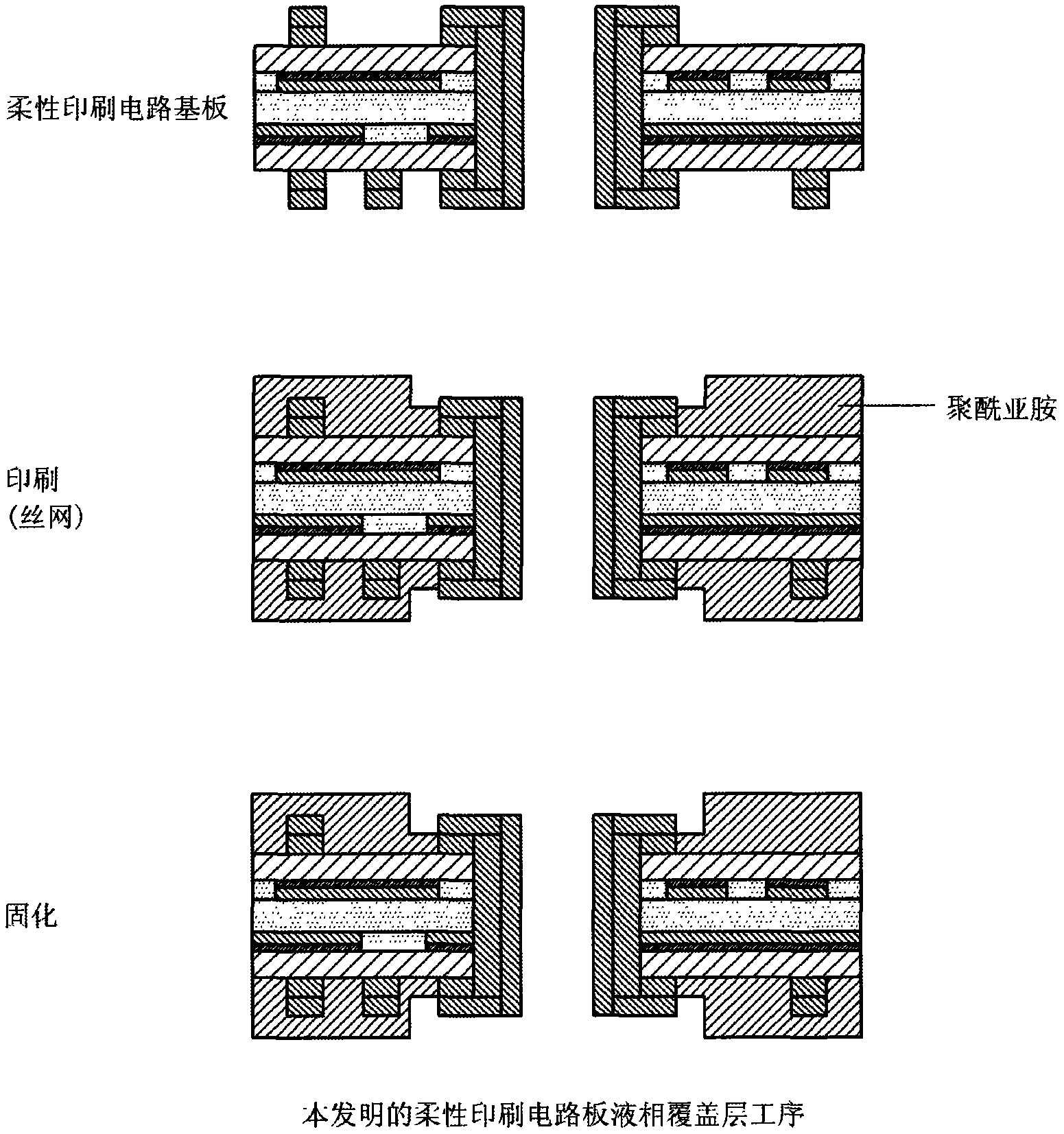

[0032] Hereinafter, the present invention will be specifically described through preferred embodiments.

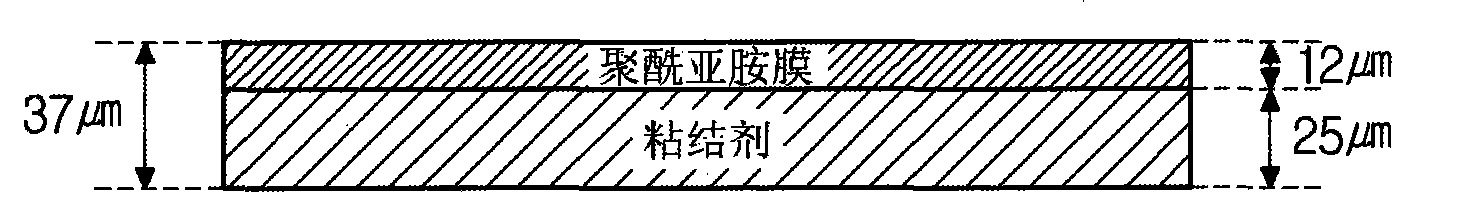

[0033] First, a polyimide is synthesized to prepare the composition for a covering layer of the present invention. Polyimide is a polymer resin formed by polymerization of acid anhydride and amine. First, polyamic acid (PAA, Polyamic Acid) is synthesized by polymerizing acid anhydride and diamine monomers, and adding additives to prepare polyimide.

[0034]As the acid anhydride (dianhydride) used at this time, there are pyromellitic dianhydride (PMDA, pyromellitic dianhydride), phthalic anhydride (PA, phthalic anhydride), 3,3'4,4'-biphenyl Tetracarboxylic dianhydride (BPDA, 3,3′4,4′-biphenyltertracarboxylic dianhydride), 3,3′4,4′-benzophenone tetracarboxylic dianhydride (BTDA, 3,3′4,4′- benxophenonetetracar boxylic dianhydride), 4′4-oxydiphthalic anhydride (ODPA, 4′4-oxydiphthalic anhydride), ethylene glycol bis-trimellitic anhydride (TMEG, trimellitic ethylene glycol), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com