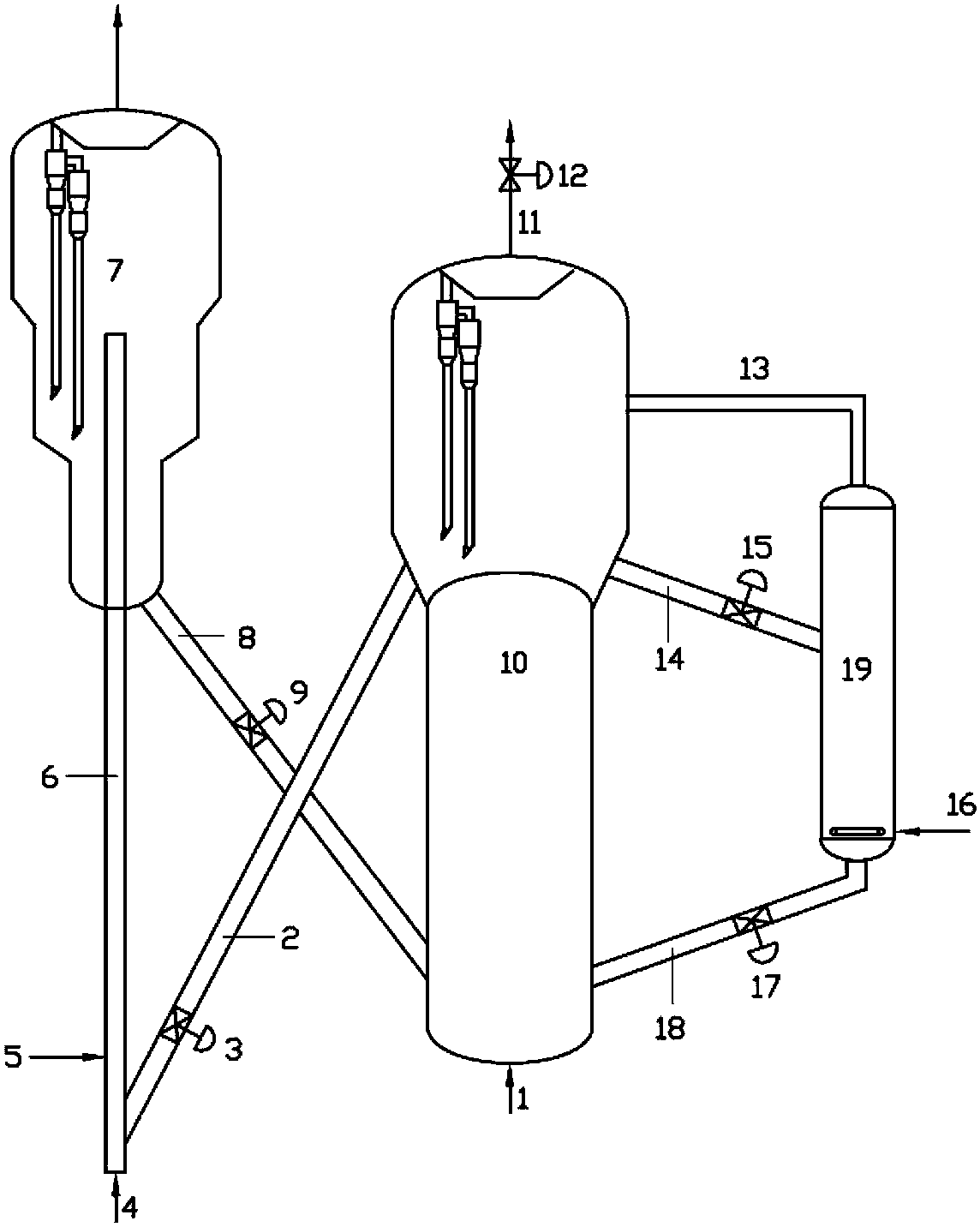

Work starting method for catalytic cracking unit

A catalytic cracking device and catalyst technology, which is applied in the direction of catalytic cracking, cracking, petroleum industry, etc., to achieve the effect of saving cost and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 illustrates the effect of hydrothermal treatment of fresh catalyst under pressurized conditions using the method provided by the present invention.

[0037] A pressurized fixed fluidized bed experimental device was used to simulate the conditions in the start-up stage of the catalytic cracking unit regenerator. Put the MMC-2 fresh catalyst into the fixed fluidized bed, and at the same time, pass the air into the bottom of the fluidized bed as the fluidized medium, and use electric heating to heat the catalyst in the fixed fluidized bed and stabilize it at 650°C to vaporize the water After being overheated to 400°C, it is passed into the bottom of the fluidized bed, and the injection of air into the fluidized bed is stopped, and the superficial linear velocity of water vapor in the fluidized bed is controlled to be 0.4 m / s. The pressure of the fixed fluidized bed is controlled at 0.4MPa through the automatic pressure regulating valve at the outlet of the fixed ...

Embodiment 2

[0039] Example 2 illustrates the effect of using the method provided by the present invention to further improve the effect of hydrothermal treatment of fresh catalyst under the conditions of temperature and high pressure.

[0040] The basic method of the experiment is the same as in Example 1, except that the pressure of the fixed fluidized bed is controlled at 2.5 MPa, the temperature of the catalyst is controlled at 670° C., and the superficial linear velocity of water vapor in the fluidized bed is 0.7 m / s. The catalyst was hydrothermally treated under the above conditions for 12 hours. The main conditions of the treatment and the microreaction activity of the catalyst after treatment are listed in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com