Compound complex type greasing agent and preparation method thereof

A technology of fatliquor and emulsifier, which is applied in the field of synthesis of compound fatliquor and its preparation, and can solve problems such as poor stability and easy rancidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

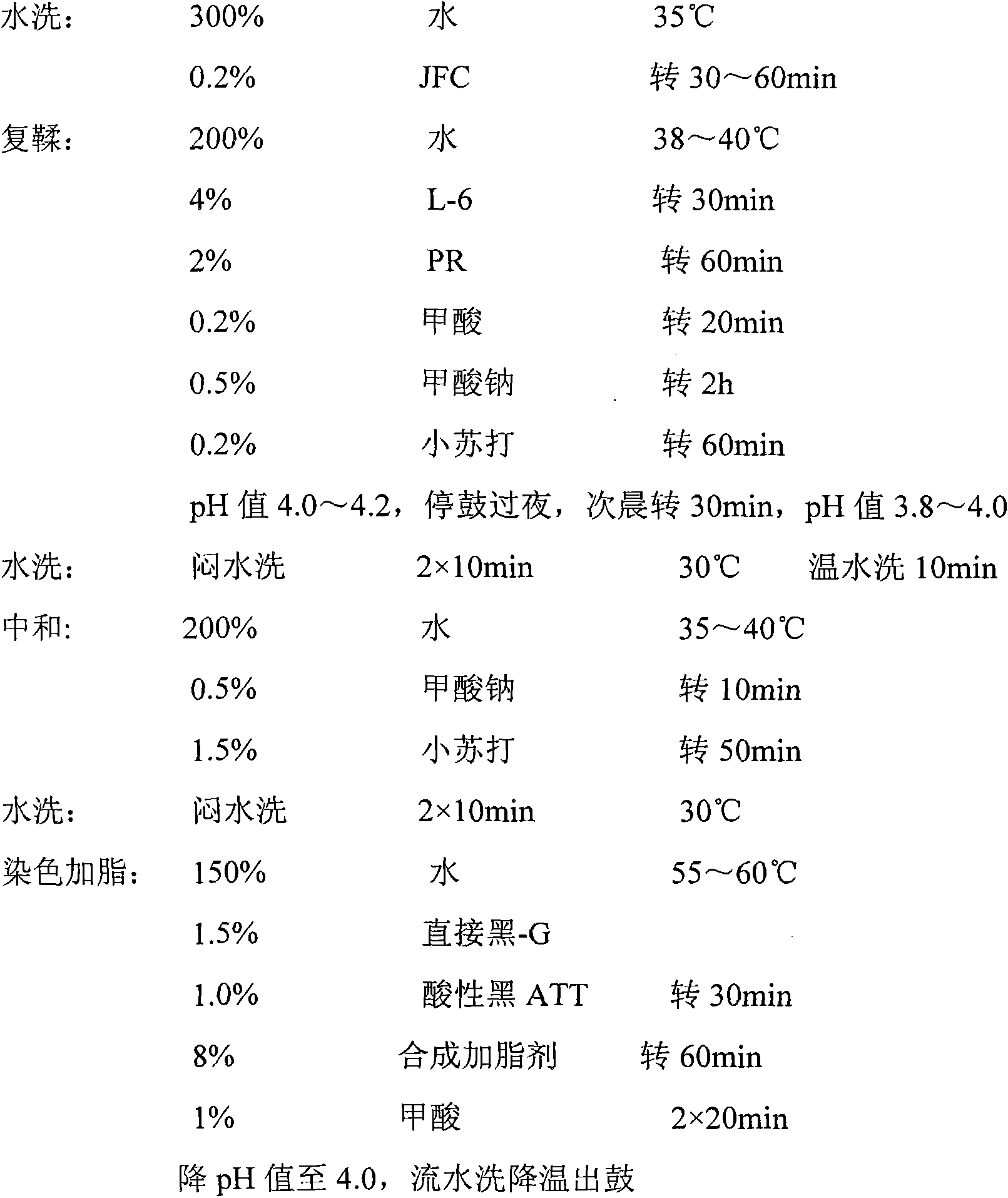

Examples

Embodiment 1

[0031] (1) Add 250 parts of triolein and 220 parts of 1303 to the reaction kettle, raise the temperature to 80°C, take a sample to detect the moisture, add 92 parts of maleic anhydride and 5 parts of antioxidant BHT under stirring after there is no moisture, and raise the temperature to 190- React at 195°C for 1 hour;

[0032] (2) Cool down to 80°C, add 10.5 parts of 1303 and 31.5 parts of AEO-9, and slowly add 168 parts of sodium hydroxide solution with a concentration of 30% by mass;

[0033] (3) Add 318 parts of sodium metabisulfite solution with a mass percent concentration of 33%, and incubate and react at 90-95°C for 4 hours;

[0034] (4) Cool down to about 60°C, add 500 parts of glyceryl trioleate, 640 parts of sulfonated oil SS (75%), 63 parts of ethylene glycol and 10 parts of preservative Kathon, then add 705 parts of water to adjust the solid content to 60% obtained 3013 parts of reddish-brown transparent liquid, which is the synthetic composite fatliquoring agent ...

Embodiment 2

[0039] (1) Add 200 parts of triolein and 200 parts of 1309 to the reaction kettle, raise the temperature to 80°C, take a sample to detect moisture, add 80 parts of maleic anhydride and 5 parts of antioxidant BHT under stirring after no moisture, and raise the temperature to 200- Reaction at 205°C for 1 hour;

[0040] (2) Cool down to 80°C, add 10 parts of 1303 and 40 parts of AEO-9, and slowly add 152 parts of sodium hydroxide solution with a concentration of 30% by mass;

[0041] (3) Add 300 parts of sodium bisulfite solution with a mass percent concentration of 33%, and incubate at 90-95° C. for 3 hours;

[0042] (4) Cool down to about 60°C, add 600 parts of glyceryl trioleate, 800 parts of sulfonated oil SS (75%), 60 parts of 1,4-butanediol and 10 parts of preservative Kathon, and then add 737 parts of water Adjust the solid content to 60% to obtain 3194 parts of reddish-brown transparent liquid, which is the synthetic composite fatliquoring agent of the present invention....

Embodiment 3

[0047] (1) Add 300 parts of glyceryl trioleate, 200 parts of 1303 and 50 parts of 1307 into the reaction kettle, raise the temperature to 80°C, take a sample to detect moisture, add 100 parts of maleic anhydride and 5 parts of antioxidant BHT under stirring after no moisture , heat up to 190-195°C and react for 1 hour;

[0048] (2) Cool down to 80°C, add 15 parts of 1303 and 45 parts of AEO-9, and slowly add 180 parts of sodium hydroxide solution with a concentration of 30% by mass;

[0049] (3) Add 200 parts of sodium metabisulfite solution with a concentration of 33% by mass and 100 parts of sodium bisulfite solution with a concentration of 33% by mass, and insulate and react at 90-95° C. for 4 hours;

[0050] (4) Cool down to about 60°C, add 500 parts of glyceryl trioleate, 500 parts of sulfonated oil SS (75%), 50 parts of ethylene glycol, 20 parts of 1,2-propylene glycol and 10 parts of preservative Cathone, and then Add 748 parts of water to adjust the solid content to 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com