Aerator of ceramic composite steel pipe

A composite steel pipe and oxygen-increasing device technology, which is applied in the coating process and coating of metal materials, can solve the problems of insufficient air, affecting product quality, etc., and achieve the effects of simple structure, favorable spontaneous combustion reaction, and convenient manufacture

Inactive Publication Date: 2014-03-26

JIANGSU DIDU PIPELINE

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when producing pipe fittings with a diameter greater than 600mm, due to the rapid reaction of thermite in the production process of ceramic composite steel pipes, a large amount of oxygen needs to be absorbed, and the air in the pipes is insufficient, which affects the quality of the products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

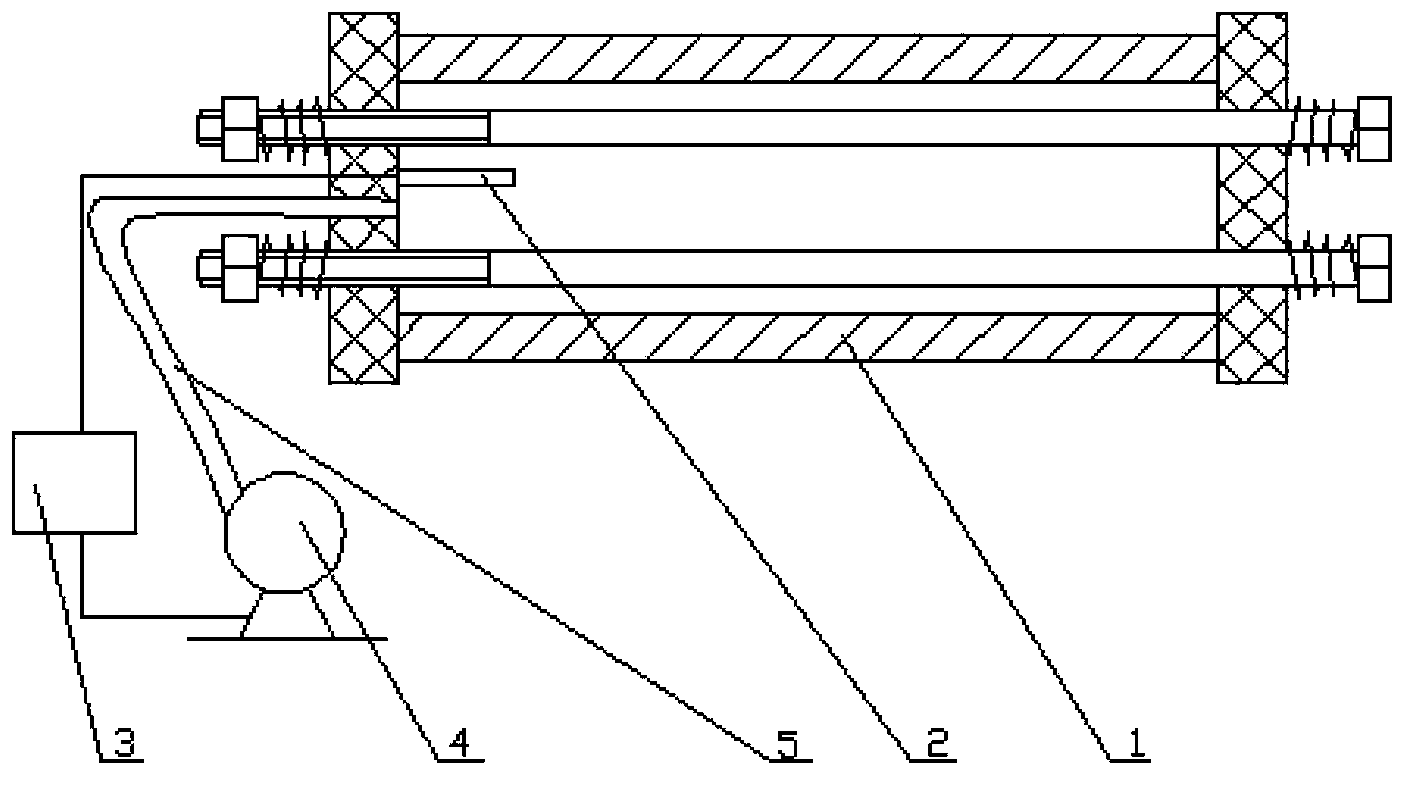

[0010] exist figure 1 Among them, the oxygenation device of the ceramic composite steel pipe includes an oxygen sensor 2, the oxygen sensor 2 is set in the ceramic composite steel pipe 1, the oxygen sensor 2 is connected to the controller 3, the controller 3 is connected to the oxygenation pump 4, and the oxygenation pump 4 is connected to the The pipe 5 communicates with the ceramic composite steel pipe 1 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention discloses an aerator of a ceramic composite steel pipe. The aerator comprises an oxygen sensor, wherein the oxygen sensor is arranged inside the ceramic composite steel pipe, and connected with a controller; the controller is connected with an aeration pump; the aeration pump is communicated with the ceramic composite steel pipe through a connecting pipe. The aerator of the ceramic composite steel pipe is simple in structure, and convenient to manufacture, oxygen is added to the ceramic composite steel pipe, and spontaneous combustion reaction of a thermite in the ceramic composite steel pipe is facilitated.

Description

technical field [0001] The invention belongs to a device for increasing oxygen, in particular to a device for increasing oxygen in the process of producing ceramic composite steel pipes. Background technique [0002] Ceramic composite steel pipes are generally manufactured by self-propagating synthesis technology. A mixture of iron oxide powder and aluminum powder is added to the steel pipe. The name of the mixture is thermite. Under the high-speed rotation of the centrifuge, the thermite will spontaneously ignite immediately after ignition. After the thermite reacts, the products are corundum and iron, which release a large amount of heat at the same time. Because the reaction is very fast, it only takes a few seconds. The light corundum is distributed on the inner wall of the iron. Due to the rapid heat absorption and heat transfer of the steel pipe, the reactants are quickly layered and solidified, and finally a ceramic composite steel pipe with a steel pipe layer, a tran...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): C23C24/10

Inventor 潘爱军王文成

Owner JIANGSU DIDU PIPELINE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap