Steel-reinforced concrete base of large-span net rack roof and construction method of steel-reinforced concrete base

A steel-reinforced concrete and construction method technology, which is applied in the processing of building materials, long-strip structural members for load-bearing, structural elements, etc. performance and other issues, to achieve the effect of solving the contradiction between architectural aesthetics and structural safety, shortening the construction period and reducing the weight of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

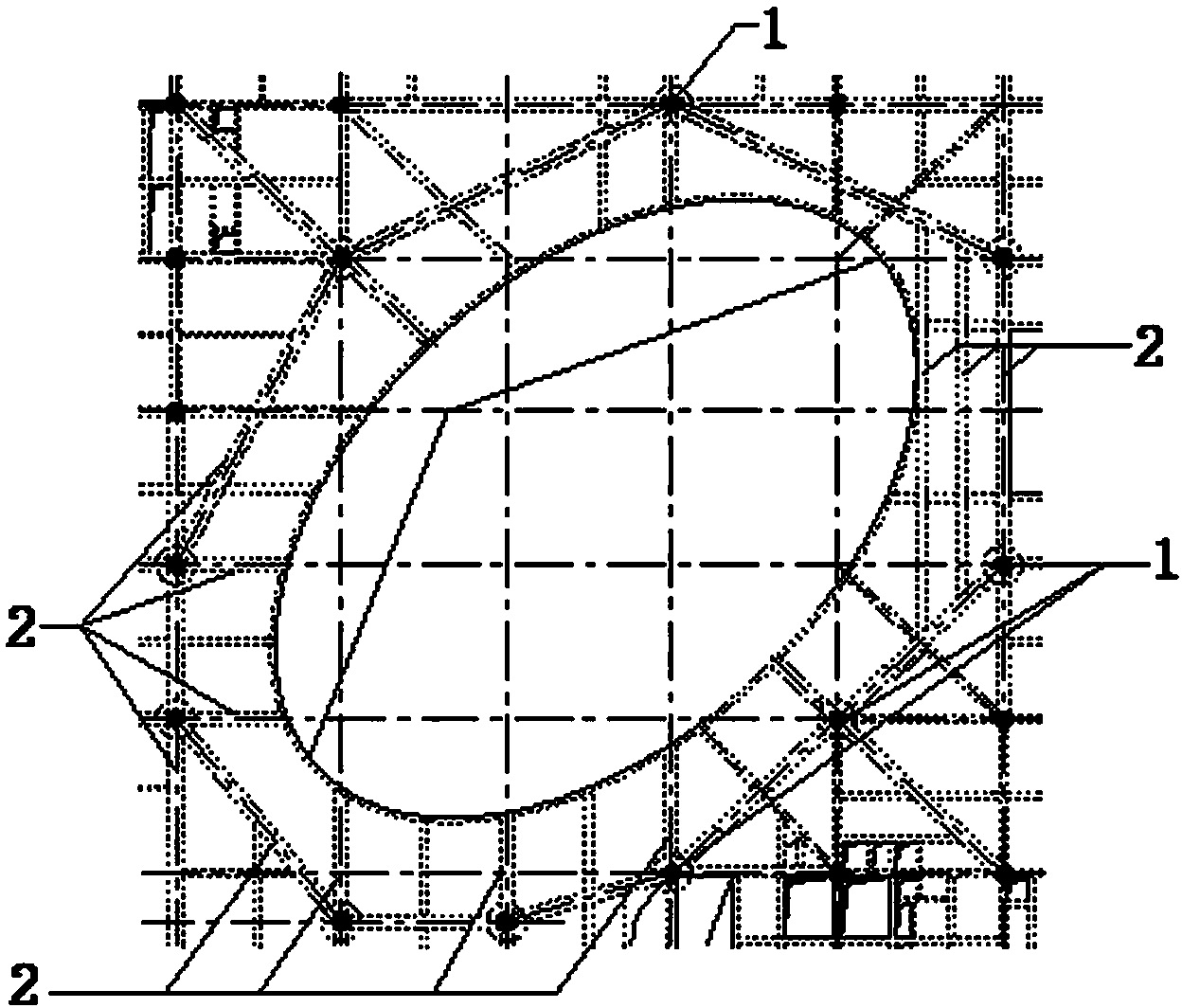

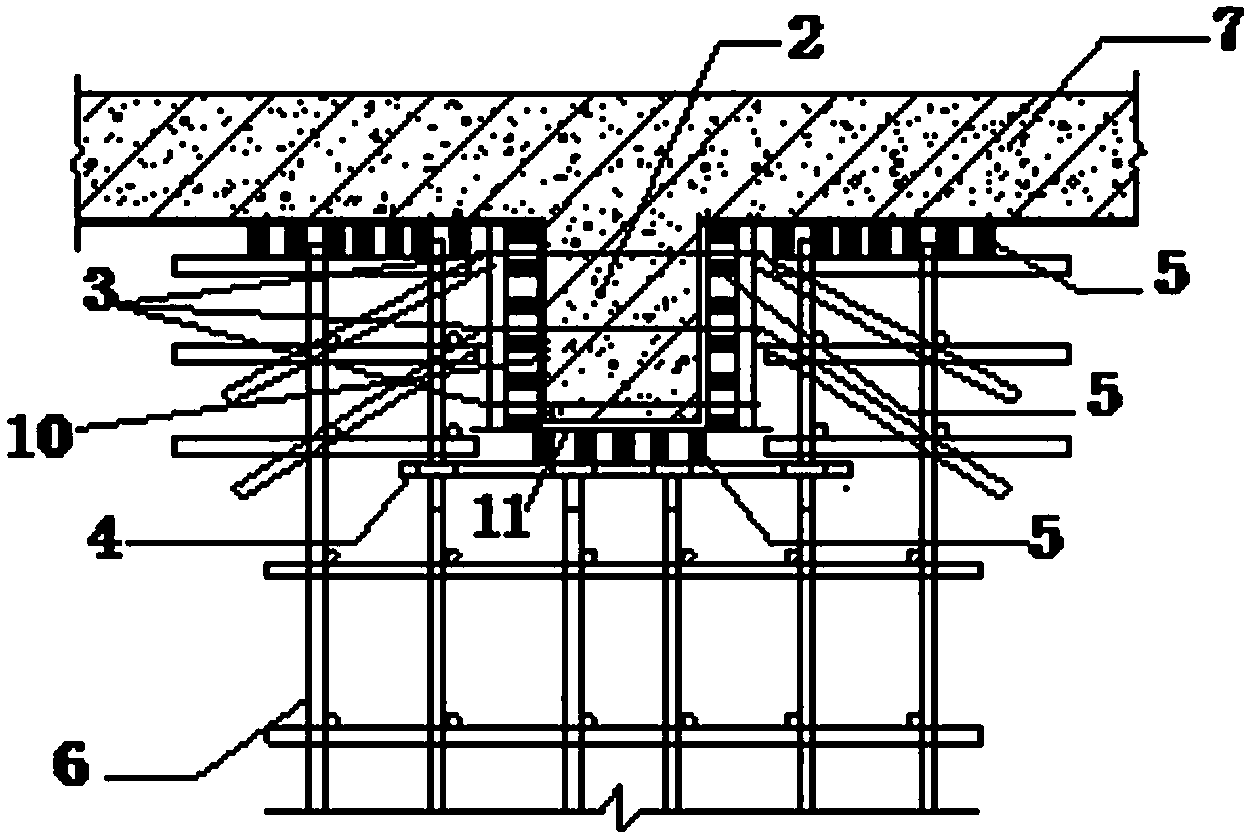

[0022] figure 1 It is a real picture of the oval grid roof of a shopping mall, such as figure 2 As shown, multiple steel-reinforced concrete columns and steel-reinforced concrete beams form the tall oval space of the commercial part, which is also the base of the grid roof. The steel-reinforced concrete base includes a circular steel-reinforced concrete column and a rectangular steel-reinforced concrete beam, and the steel-reinforced concrete beam is supported on the steel-reinforced concrete column; steel bars are provided in the steel-reinforced concrete column and the steel-reinforced concrete beam; The steel-reinforced concrete beam includes two-end support beams and cantilevered beams, and the steel-reinforced concrete beam forms an oval space for supporting the grid roof on the upper part of the building.

[0023] The diameter of the steel reinforced concrete column is 1000mm, the steel frame inside the column is φ510×24mm steel pipe, and the material is Q345B; the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com