Safe releasing tool for horizontal well

A technology for throwing away tools and horizontal wells, which is applied in wellbore/well parts, earthwork drilling and production, etc. It can solve problems such as unreasonable structure, low work efficiency, cumbersome installation and use, etc., and achieve reasonable structural design, saving production costs, The effect of low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

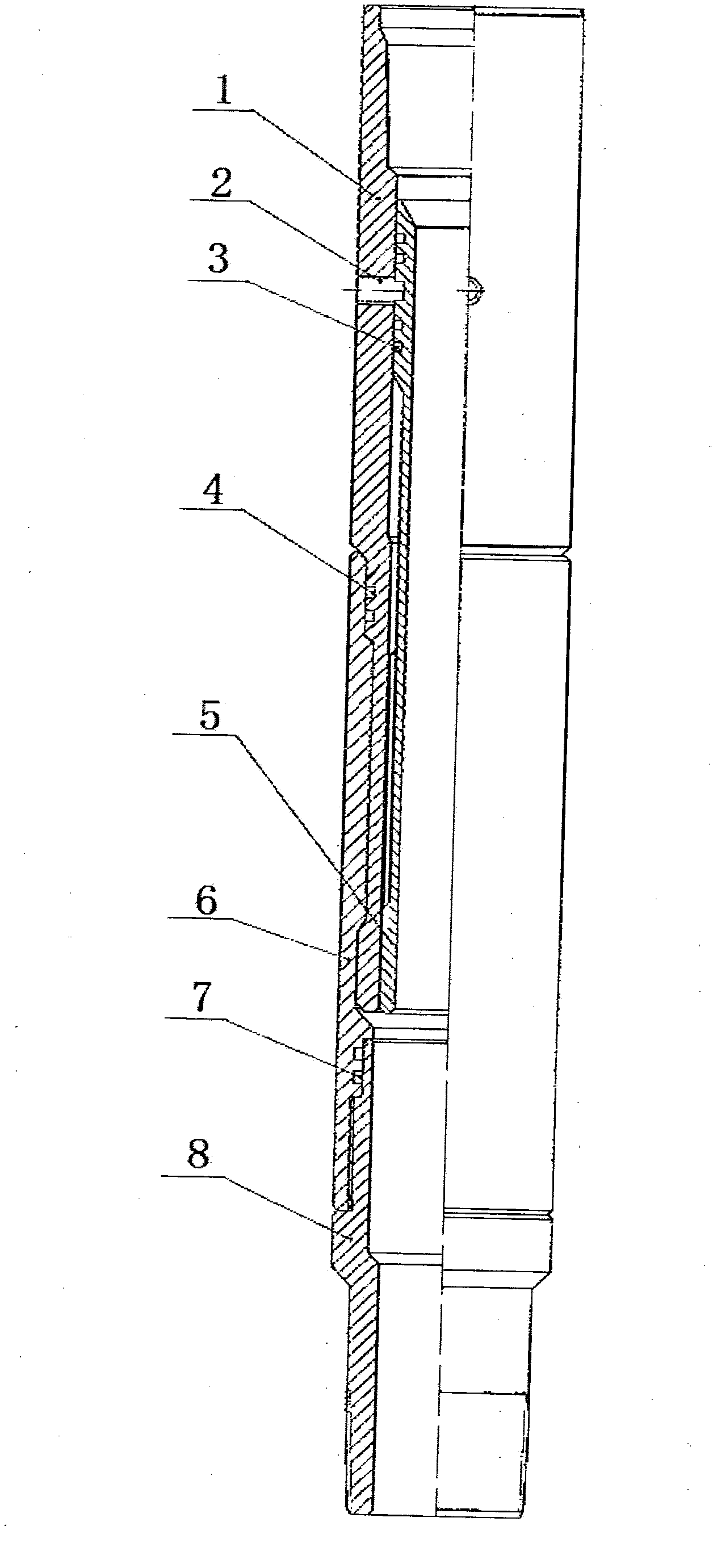

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] A safe hands-free tool for horizontal wells, comprising an upper joint 1, shear nails 2, a seal ring 3, a seal ring A4, a hands-free sliding sleeve 5, a seal sleeve 6, a seal ring C7, and a lower joint 8, and is characterized in that The sealing ring C7 is embedded in the sealing groove of the sealing sleeve 6, and then connected with the lower joint 8 through threads and tightened; the sealing ring A4 is embedded in the sealing groove of the upper joint 1, and the sealing ring 3 is embedded in the sliding sleeve 5; install the lower end of the upper joint 1 into the inner groove of the sealing sleeve 6, and install the sliding sleeve 5 of the upper sealing ring 3 into the inner hole of the upper joint 1, so that the upper joint 1 The lower end is just pressed into the inner groove of the sealing sleeve 6 . Install the scissors 2 into the scissors grooves of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com