Energy storage and pressurizing type hydraulic station

A technology of hydraulic station and supercharger, applied in the hydraulic field, can solve the problems of huge system, system vibration, affecting the normal operation of the system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

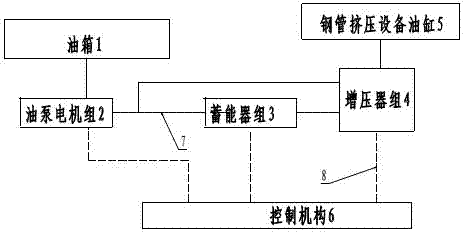

[0025] Referring to Fig. 1, the present invention comprises fuel tank 1, oil pump motor unit 2, accumulator group 3, supercharger group 4, control mechanism 6 and hydraulic pipeline 7, described fuel tank 1, oil pump motor unit 2, accumulator group 3. The supercharger group 4 is connected through the hydraulic pipeline 7, the oil tank 1 is fixedly installed above the oil pump motor unit 2, the oil circuit inlet of the oil pump motor unit 2 is connected to the oil tank 1, and the oil circuit outlet is connected to the energy storage The accumulator group 3 is connected, and the accumulator group 3 is composed of a group of accumulator units connected in parallel, and the supercharger group 4 is connected behind the accumulator group 3, and the supercharger group 4 includes two groups of parallel The supercharger units are provided with two superchargers in each supercharger unit.

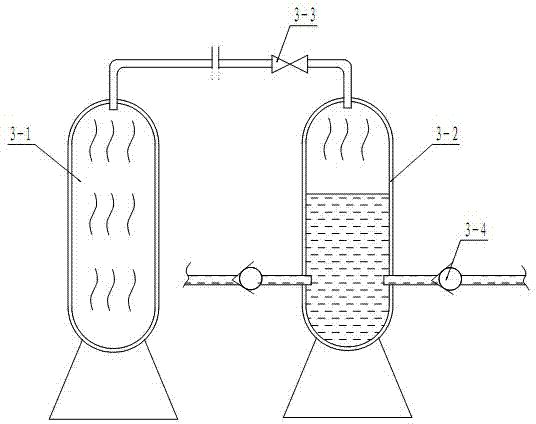

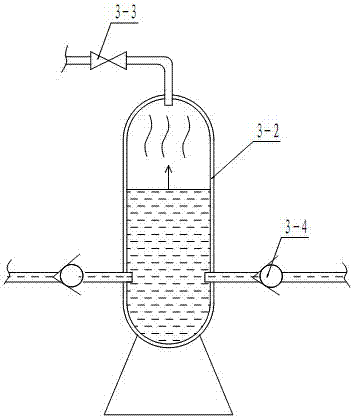

[0026] see figure 1 , figure 2 , Figure 5 , the accumulator unit of the present invention co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com