Novel pipeline connecting pressure-resisting flange and application

A flange and pipeline technology, applied in the field of pipeline connection design, can solve the problems of insufficient flange stiffness, warping deformation, neglect of compressive performance, short flange life, etc., to avoid distortion or damage, easy alignment, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

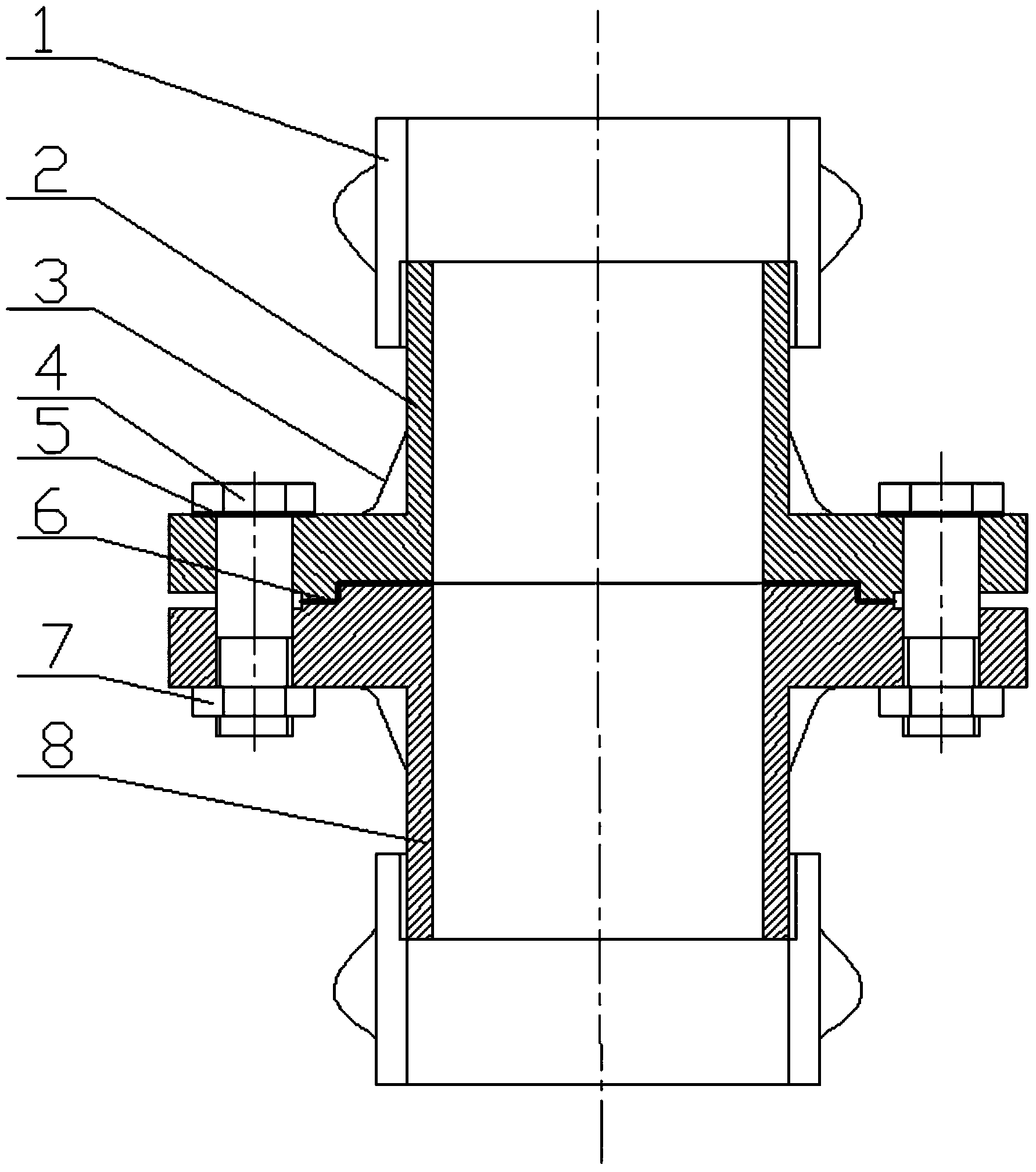

[0017] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, the inner diameter of the pressure-resistant pipe 1 is larger than the outer diameter of the flange connection pipe. After the pipe connection pipe is welded to the concave-convex flange, one end of the pressure-resistant pipe 1 is welded together with the pipe connection pipe, and the other end of the pressure-resistant pipe 1 is a threaded structure. The concave flange 2 and the convex flange 8 are threaded to make the connection between the flange and the pipeline tighter, and to prevent the risk of cracks at the connection between the flange and the pipeline caused by excessive internal pressure of the pipeline. A pair of concave and convex Face flange 28, middle dress flange gasket 6, connect with bolt 4, the nut 7 that bolt 4 matches with it is fixed together.

[0018] Finally, it should be noted that: the above embodiments are only used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com