U-shaped structure sapphire fiber grating temperature and stress sensor and manufacturing method thereof

A stress sensor and fiber grating technology, which is applied in the field of U-shaped structure fiber grating temperature stress sensor and its preparation, can solve the problems of inability to realize simultaneous measurement of temperature stress, measurement limitation, and difficulty in ensuring the adhesion between fiber grating and metal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is implemented on the premise of the technical solution of the present invention, and the detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

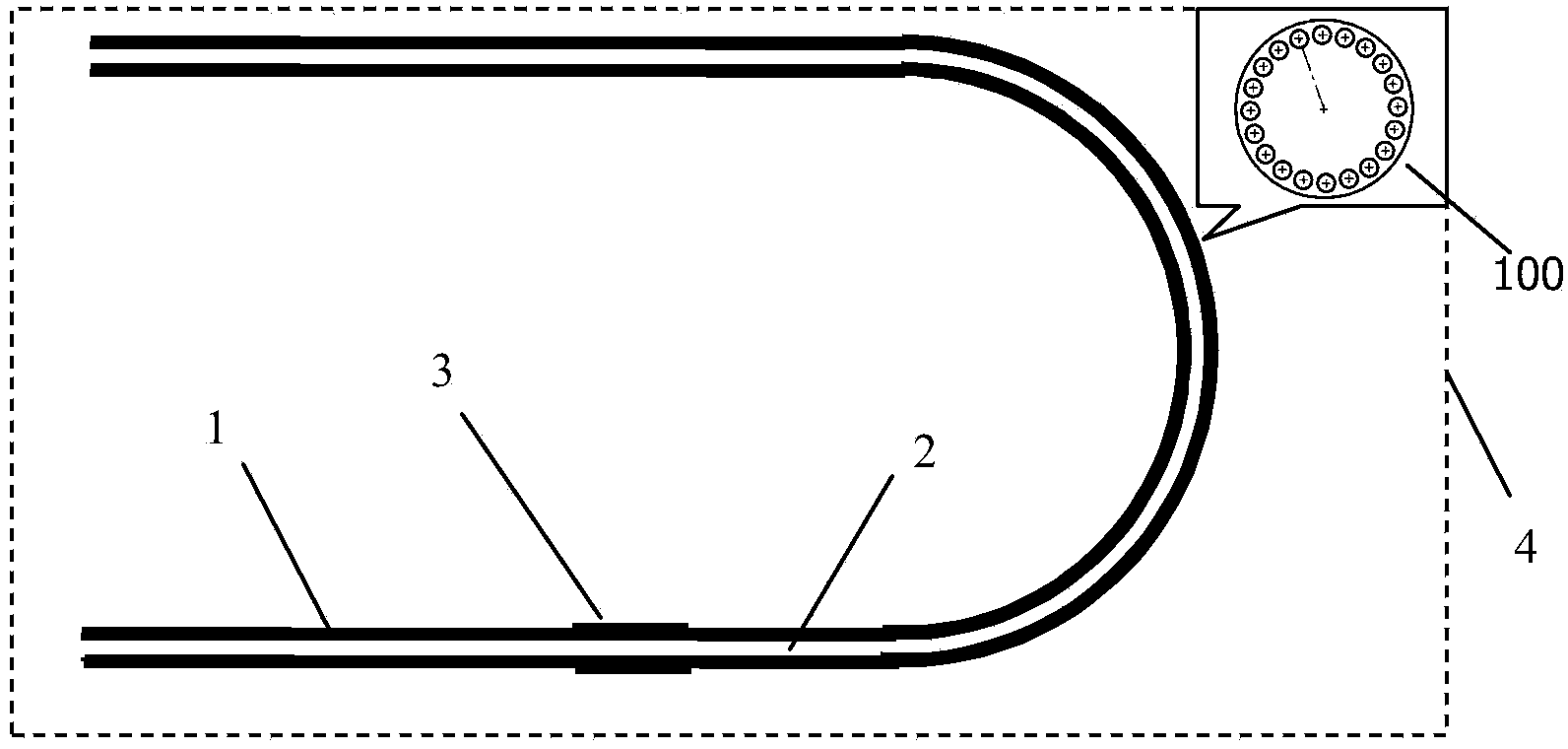

[0047] Such as figure 1 As shown, the present invention is a sapphire fiber grating temperature and stress sensor with a U-shaped structure, including a U-shaped sapphire optical fiber 1 with a micro-hole structure on the end face, wherein the sapphire optical fiber 1 is provided with a surface doped with magnesium oxide The formed magnesium-aluminum spinel long-period fiber grating 2 and a conventional long-period grating 2 are arranged on one side of the sapphire fiber U-shaped structure, wherein the magnesium-aluminum spinel long-period fiber grating There is a crystal thin film 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com