Device and method for measuring effective porosity of low-permeability rock on basis of inert gas experiment

A technology of effective porosity and inert gas, which is applied in the direction of measuring devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of large error in porosity measurement and unstable results, and achieve high test accuracy, The effect of short experimental period and simple calculation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

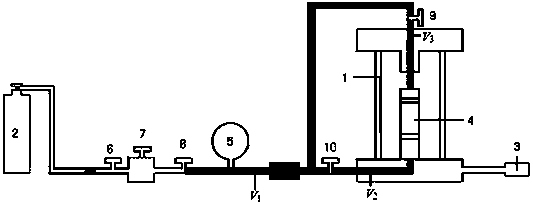

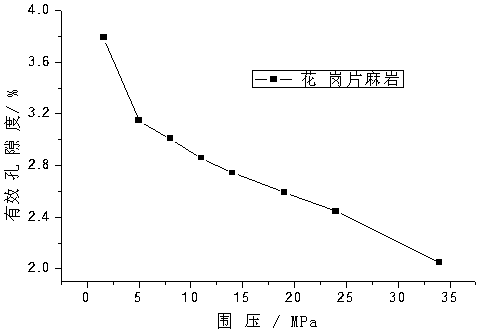

[0034] 1. Select the natural low-permeability rock-Late Proterozoic granite gneiss, process the rock sample into a cylindrical shape, measure the diameter and height, and calculate the volume of the rock sample V ;

[0035] 2. After the rock sample is covered with high-performance rubber, put it into the pressure chamber 1, and adjust the position of the sample to make it balanced;

[0036] 3. Turn on the confining pressure control device 3 to apply the confining pressure to the predetermined value and then close it, so that the confining pressure is continuously stable at the predetermined value;

[0037] 4. Close the first valve, open the second to fifth valves to connect all the pipelines with the outside atmosphere, leave it for a period of time until the gas inside the instrument is discharged, and calibrate the high-precision pressure gauge 5 to 0;

[0038] 5. Close the second, fourth and fifth valves, open the first and third valves, and open the air pressure loading s...

Embodiment 2

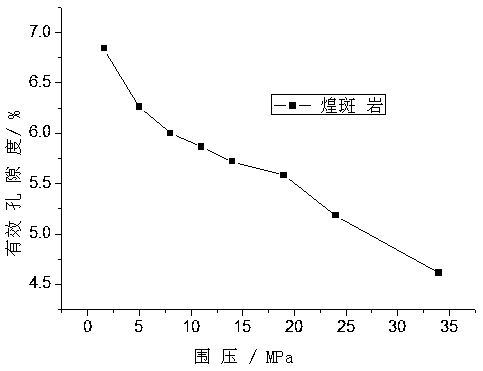

[0051] 1. Select the natural low-permeability rock-Cretaceous lamprophyre, process the rock sample into a cylindrical shape, measure the diameter and height, measure and calculate the volume of the rock sample V ;

[0052] 2. After the rock sample is covered with high-performance rubber, put it into the pressure chamber 1, and adjust the position of the sample to make it balanced;

[0053] 3. Turn on the confining pressure control device 3 to apply the confining pressure to the predetermined value and then close it, so that the confining pressure is continuously stable at the predetermined value;

[0054] 4. Close the first valve, open the second to fifth valves to connect all the pipelines with the outside atmosphere, leave it for a period of time until the gas inside the instrument is discharged, and calibrate the high-precision pressure gauge 5 to 0;

[0055] 5. Close the second, fourth and fifth valves, open the first and third valves, and open the air pressure loading sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com