Printed circuit element polarity machine vision detection method and device

A machine vision inspection, printed circuit technology, applied in the direction of instruments, measuring electricity, measuring devices, etc., can solve problems such as lack of interference, achieve the effect of improving product quality, improving the degree of inspection automation, and saving personnel costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

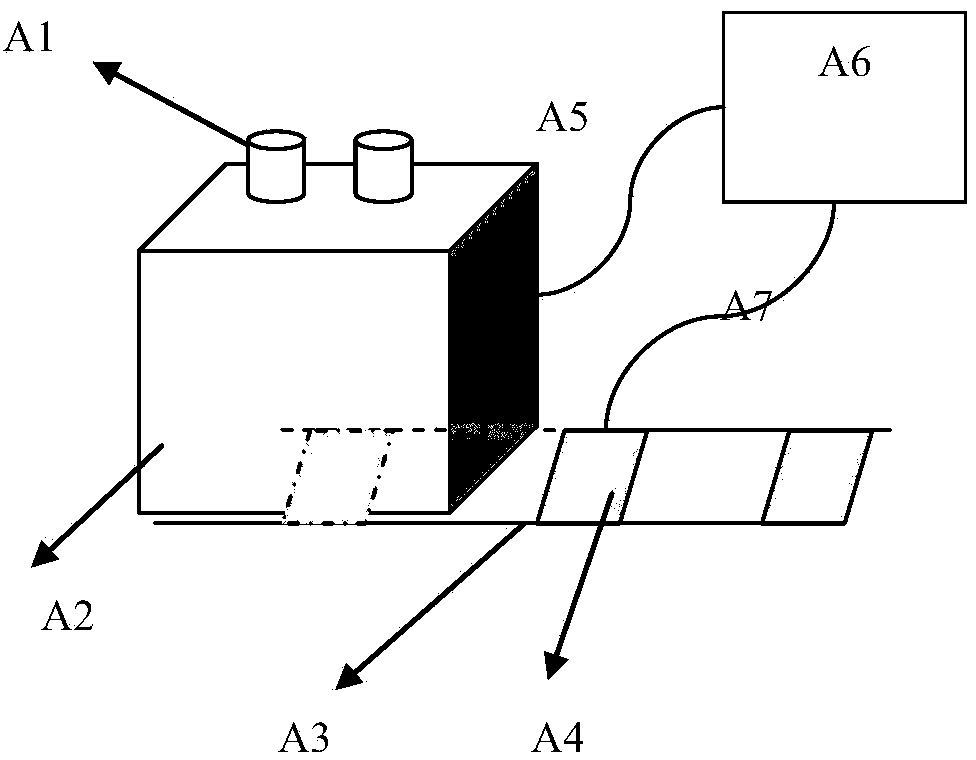

[0042] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0043] The machine vision detection method of the printed circuit element polarity of the present invention comprises the following steps:

[0044] (1) Place different types of components to be tested in sequence in the test area of a closed work box containing an adjustable light source, take multiple photos for each type of component, and obtain component samples;

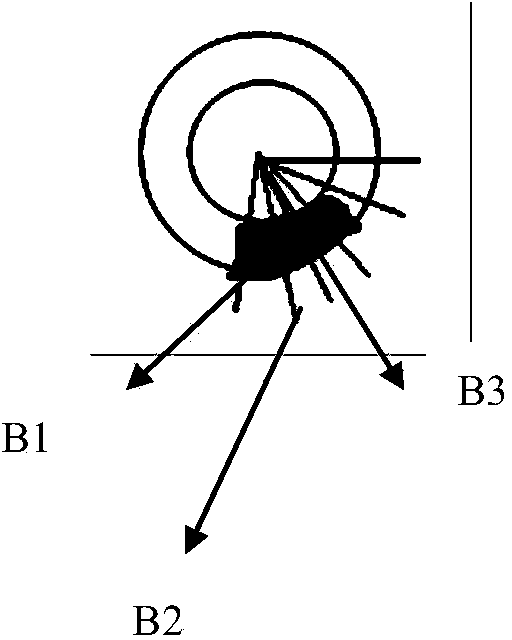

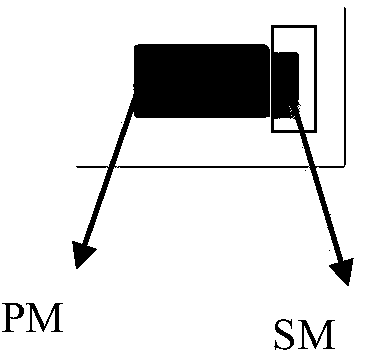

[0045] (2) For component samples, classify according to the type of capacitance or diode, determine the detection parameters required for each type of component to be tested, and form all the used detection parameters into a detection parameter set; the detection parameter set is: to be detected Component model, capacitor polarity identification binarization threshold, capacitor polarity identification direction, capacitor body outline circle diameter and pixel area size, capacitor polarity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com