Anti-static display panel

A display panel, anti-static technology, applied in instruments, nonlinear optics, optics, etc., can solve the problem that the static electricity of the thin film transistor substrate cannot be effectively discharged, and achieve the effect of avoiding abnormal display.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

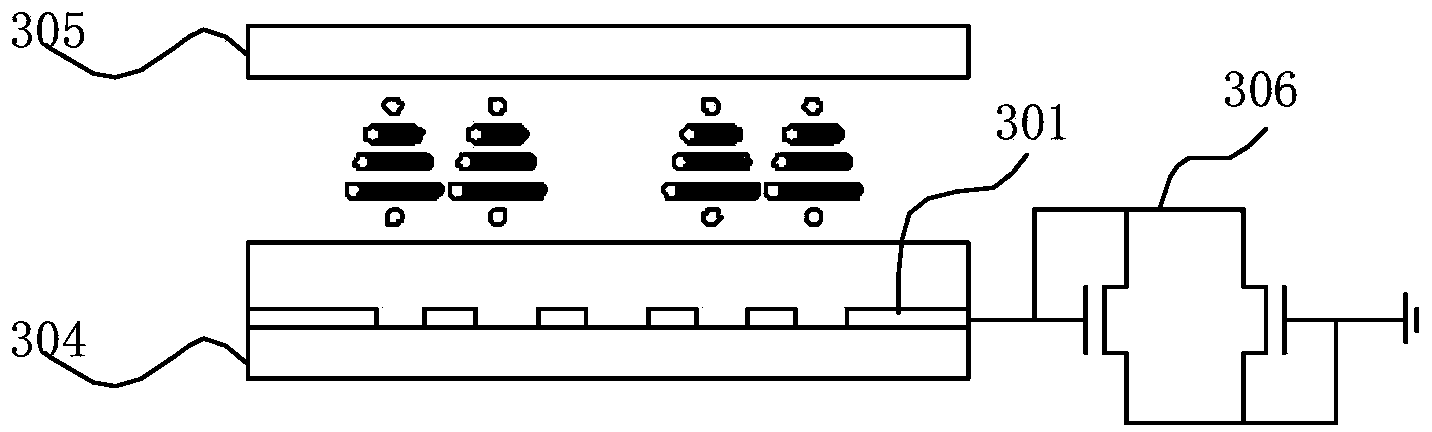

[0046] Such as image 3 As shown, a thin film transistor liquid crystal display panel provided in Embodiment 1 of the present invention includes: a TFT substrate 304, a CF substrate 305, a liquid crystal disposed between the TFT substrate and the CF substrate, and the liquid crystal display panel includes a display area and a non-display area, the non-display area is arranged around the display area, and the common electrode 301 surrounding the display area is arranged in the non-display area.

[0047] It also includes: an electrostatic protection device (ESD device) 306, one end of which is connected to the common electrode 301, and the other end is grounded.

[0048] The electrostatic protection device 306 can be one-stage, two-stage or multi-stage.

[0049] Preferably, the electrostatic protection device 306 is one-stage or two-stage.

[0050] Figure 4 with Figure 5 It is a schematic circuit diagram of a one-level and two-level ESD protection device. Figure 4 The el...

Embodiment 2

[0055] Such as Figure 6 As shown, the thin film transistor substrate provided by the second embodiment of the present invention at least includes a display area AA, and a non-display area surrounding the display area AA; in the non-display area, a display area surrounding the thin film transistor substrate is provided An ESD device 606 is also provided in the non-display area; the common electrode 601 is connected to one end of the ESD device 606; a ground connection around the display area of the thin film transistor substrate is also provided in the non-display area The protection ring 607; the other end of the ESD device 606 is connected to the protection ring 607.

[0056] The material of the protection ring 607 is metal.

[0057] The guard loop potential of the guard loop 607 is provided by a peripheral driving circuit.

[0058] At least two ends of the protection loop 607 are grounded.

[0059] In the above-mentioned thin film transistor liquid crystal display pane...

Embodiment 3

[0062] As shown in FIG. 7( a ), Embodiment 3 of the present invention provides an IPS-LCD display panel, including: a TFT substrate 704 , a CF substrate 705 , and liquid crystal disposed between the TFT substrate and the CF substrate. A transparent conductive layer 708 is disposed on the CF substrate.

[0063] As shown in FIG. 7( b ), the TFT substrate 704 includes a display area AA and a non-display area, and the non-display area surrounds the display area AA.

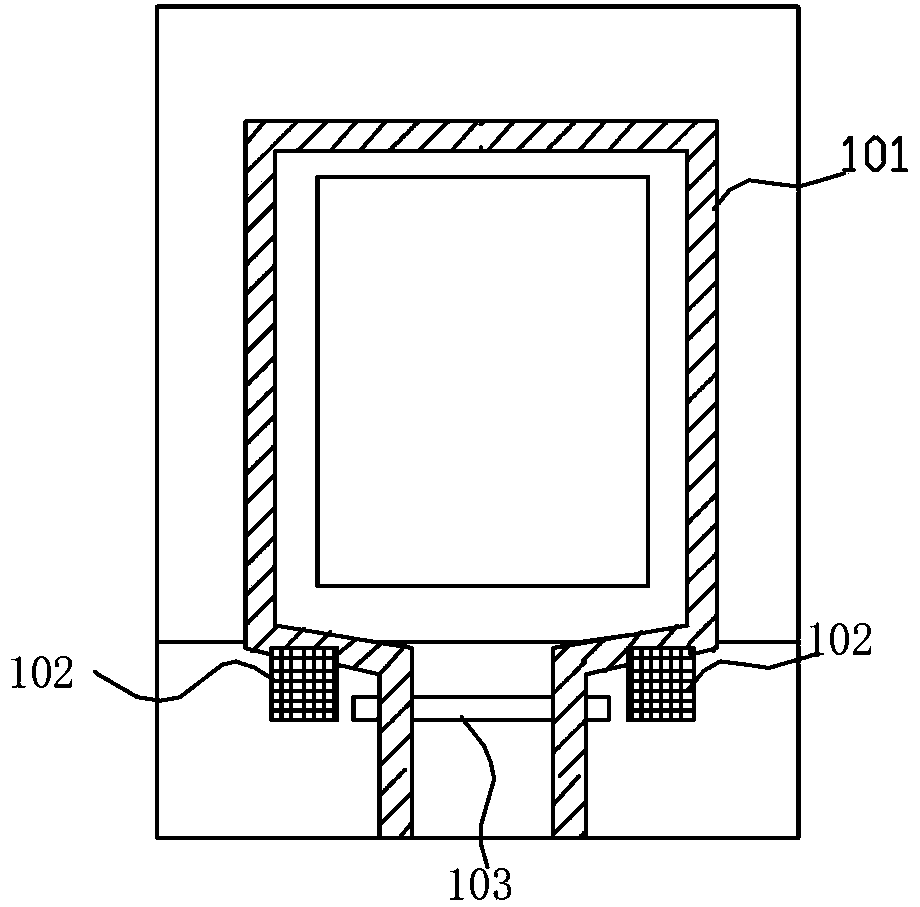

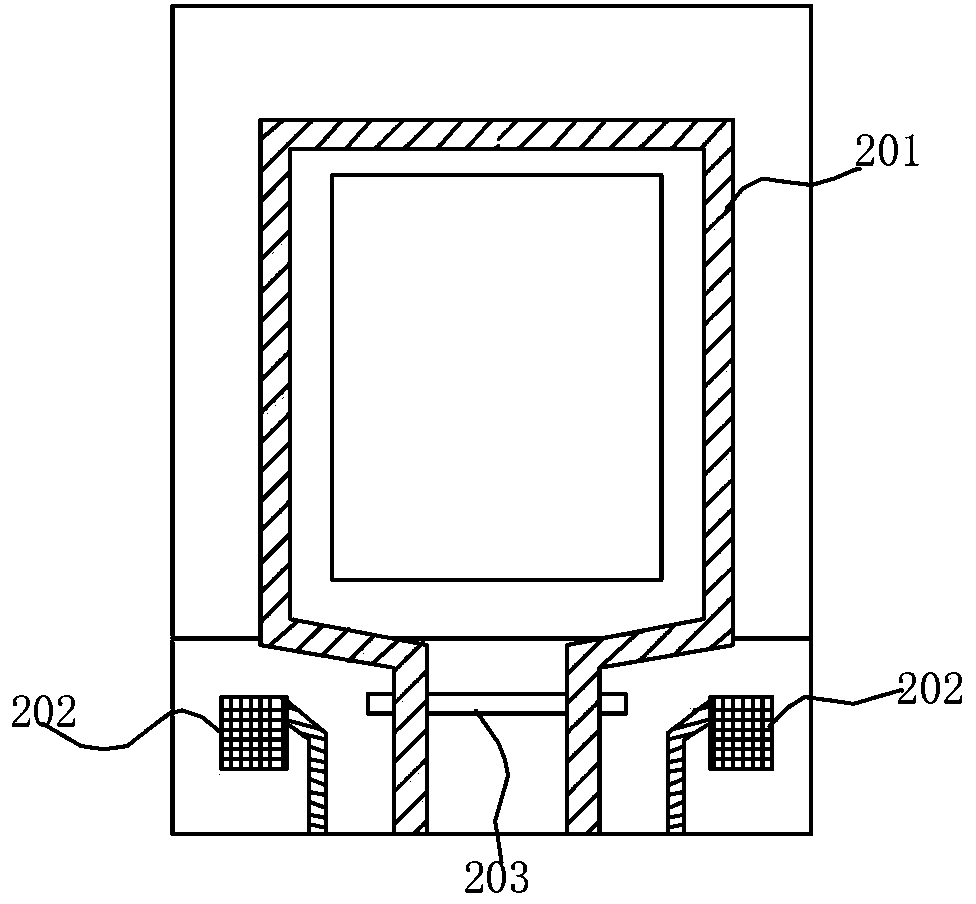

[0064] The common electrode 701 is disposed in the non-display area and surrounds the display area AA. An ESD device 706 is arranged in the non-display area; the common electrode 701 is connected to one end of the ESD device 706; a grounded protection loop 707 is also arranged in the non-display area, and the protection loop 707 surrounds the The display area; the other end of the ESD device 706 is connected to the protection ring 707. At least one conductive pad 702 is arranged on the guard ring 707 . The conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com