Counting device and counting method for metallurgy bars

A technology of counting device and counting method, which is applied in the direction of counting mechanism/items, instruments, etc., can solve the problems of not being able to truly reflect the actual diameter of the bar, high requirements for light stability, and affecting counting accuracy, so as to improve anti-interference ability, Suitable for popularization and application, with high counting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention relates to a metallurgical rod counting device and a method for counting metallurgical rods using the device.

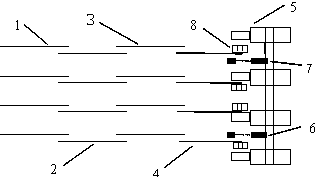

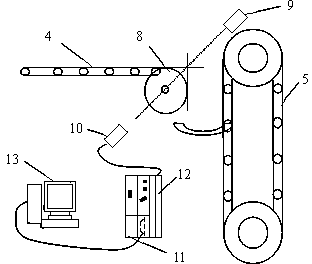

[0025] As shown in the figure, this metallurgical bar counting device includes a conveyor chain, a first group of photoelectric counting gratings 6 , a second group of photoelectric counting gratings 7 , a collecting device 5 , a counting template 12 , a PLC 11 , a counting template 12 , and a PC 13 .

[0026] The figure shows that the conveyor chain is divided into multiple sections, and the multi-section conveyor chain is connected end to end. The transmission speed of the rear conveyor chain is greater than that of the front conveyor chain. The distance between the bars is opened by the differential speed to separate the steel. The front end of the first section of the conveyor chain 1 is connected to the steel moving device, and the rear end of the last section of the conveyor chain is connected to the collection device 5, and the bars are tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com