Large warp silicon wafer pre-alignment device and method

A pre-alignment and silicon wafer technology, which is applied in photolithographic process exposure devices, optics, instruments, etc., can solve the problem of increased vertical vibration at the edge of large warped silicon wafers, blurred images at the edge of silicon wafers, and inability to perform pre-alignment And other problems, to achieve the effect of clear image on the edge of the silicon wafer, high alignment accuracy, increased convenience and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below, the present invention will be further described in detail in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

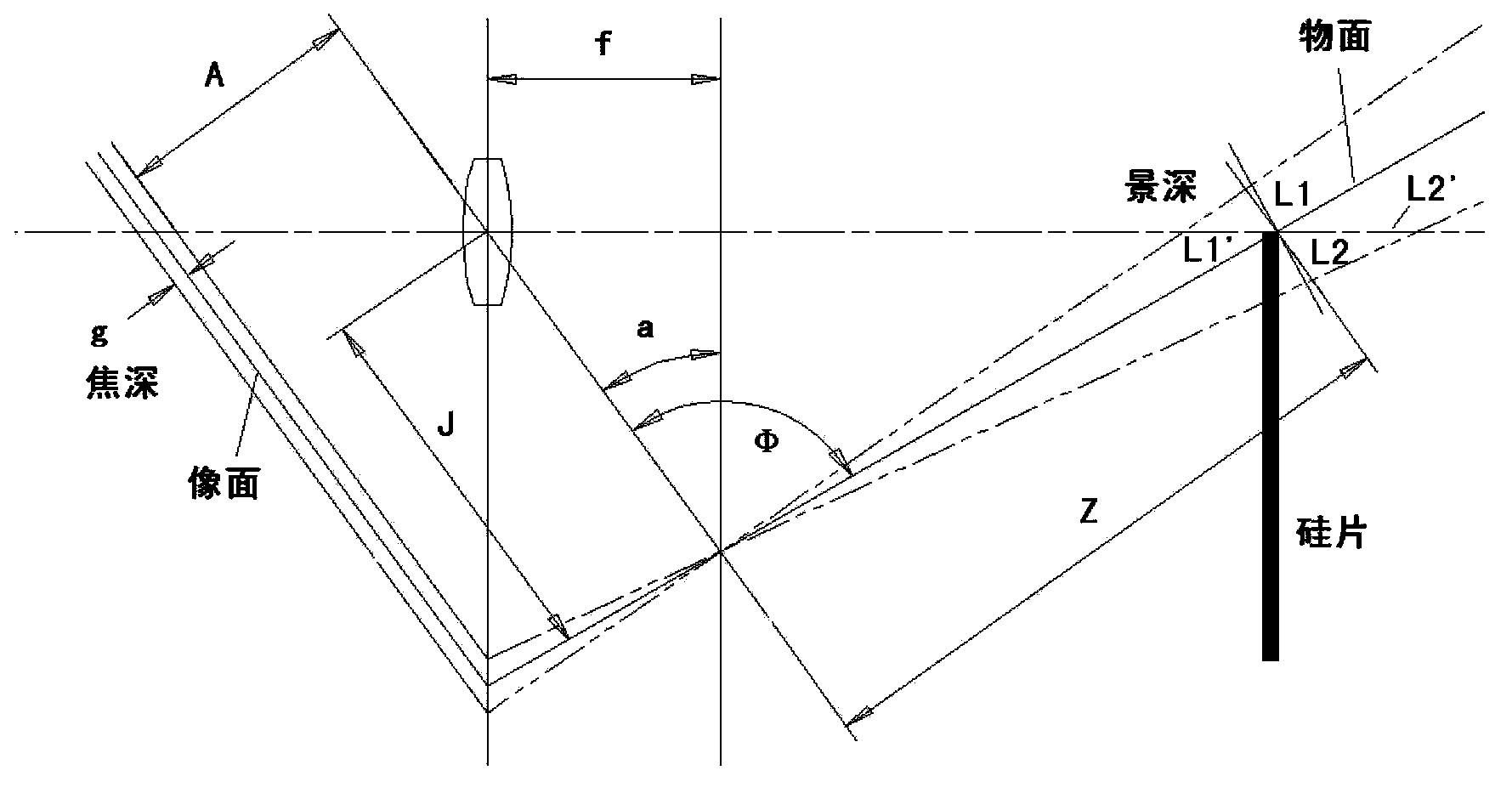

[0031] Due to the large deformation of the edge of the large warped silicon wafer, and when the size of the silicon wafer increases, the edge of the rotating silicon wafer vibrates greatly, which causes the image quality of the edge of the silicon wafer to deteriorate, and the pre-alignment accuracy decreases or cannot be completed. The invention provides a device and method for pre-alignment of silicon wafers used in photolithography machines, aiming to solve the problems of centering and orientation of large warped silicon wafers.

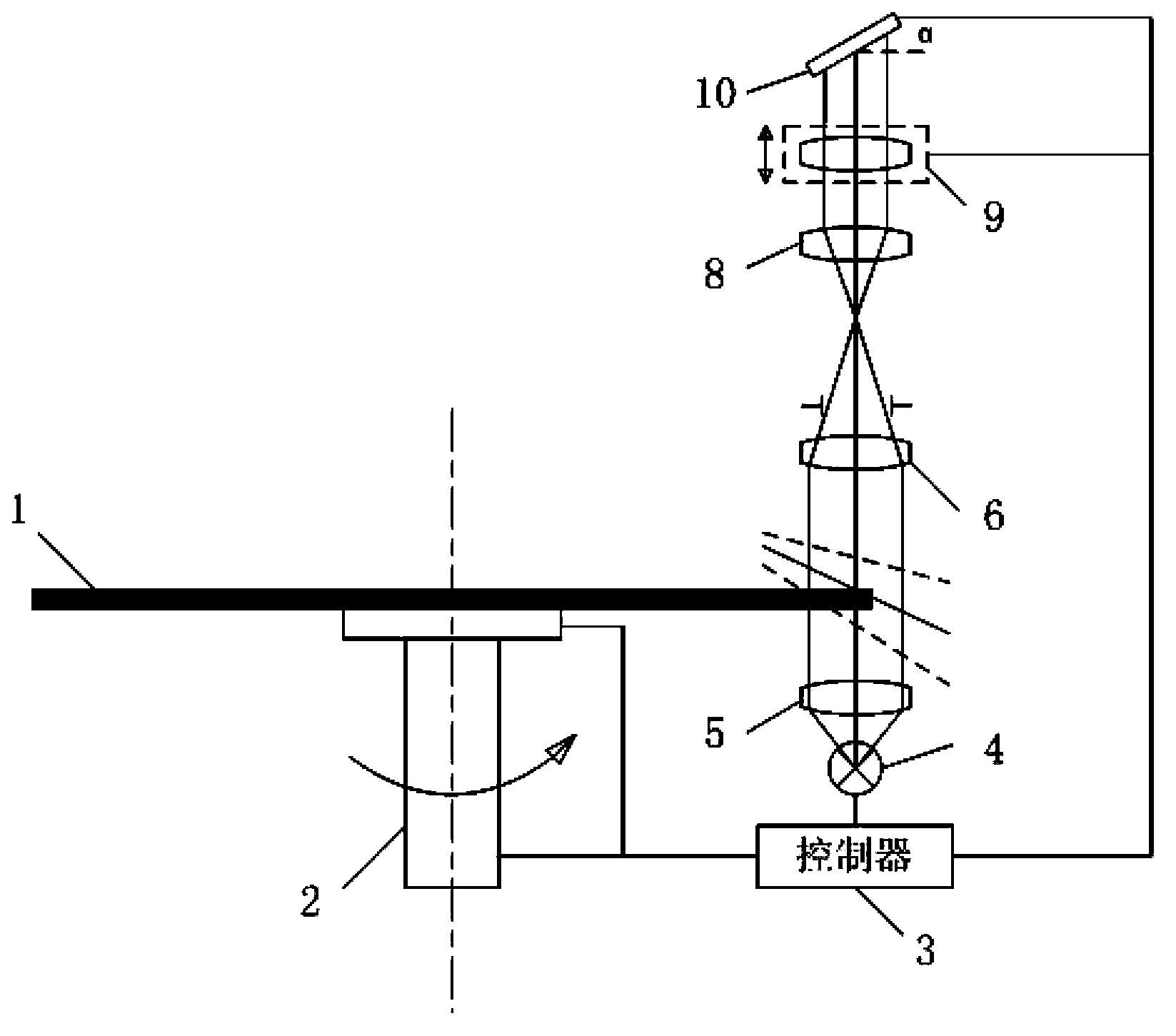

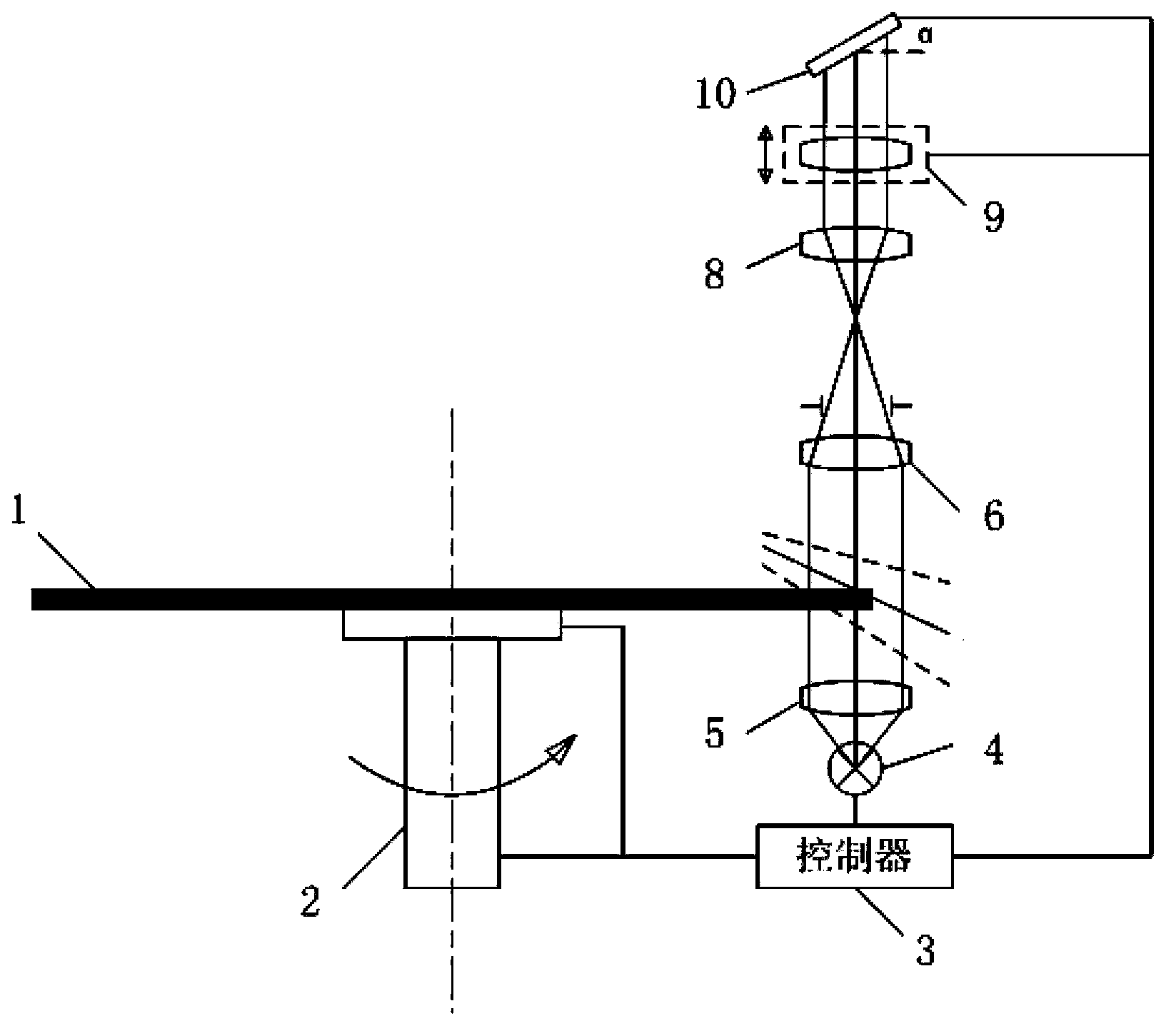

[0032] figure 1 It is a composition di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com