Terminal box

A terminal box and box technology, which is applied to the board/panel/desk of the substation/switchgear, the shell of the substation/distribution device, and the cooling/ventilation of the substation/switchgear, etc. , heat dissipation, etc., to prevent lightning strikes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

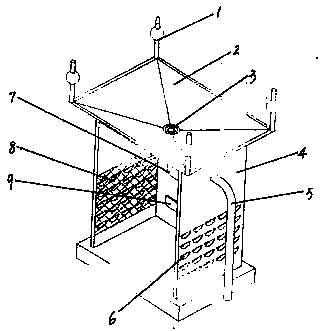

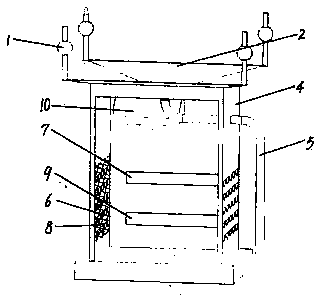

[0011] as attached figure 1 , 2 As shown, it includes a box body 4, a cover 2 arranged on the box body 4, a temperature sensor 7 arranged in the box body 4, a humidity sensor 9 arranged in the box body 4, and an air conditioner 10 arranged in the box body 4; The cover 2 is funnel-shaped, with a through hole 3 in the center; the through hole 3 is connected to one end of the discharge pipe 5, and the other end of the discharge pipe 5 is set outside the box body 4; the cover 2 is provided with a lightning rod 1, which can effectively prevent the lightning during the lightning-prone season. Struck by lightning; louvers 6 are set on the side of the box body 4 to dissipate the heat generated in the terminal box; steel wire mesh 8 is set on the inside of the louvers 6, which can effectively prevent insects and small animals from entering the box through the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com